The Moment of Truth, and the Danger that Follows

A beekeeper places a single drop of honey onto the glass prism. A quick look through the eyepiece reveals the sharp blue-and-white line against the scale: 17.8%. Perfect. The moisture content is exactly where it needs to be for stable, high-quality honey.

The immediate task is done. The natural impulse is to record the number, set the instrument down, and move to the next barrel.

This is the most dangerous moment for the refractometer. The measurement itself is only the first half of the job. The second, and arguably more critical half, is the disciplined process that happens after the reading is taken. It’s a process we often neglect because our brain has already received its reward: the data.

The Cognitive Blind Spot of "Later"

We are wired to prioritize the primary task and downgrade the cleanup. "I'll clean it later," we think. A single, forgotten drop of honey seems trivial.

But this is a cognitive blind spot. We fail to appreciate the compounding cost of this small neglect. That single drop doesn’t just sit there; it begins a process of crystallization and corrosion that silently undermines the core function of this precision instrument.

This isn't about laziness; it's about underestimating how a simple sugar solution can wage war on optical physics.

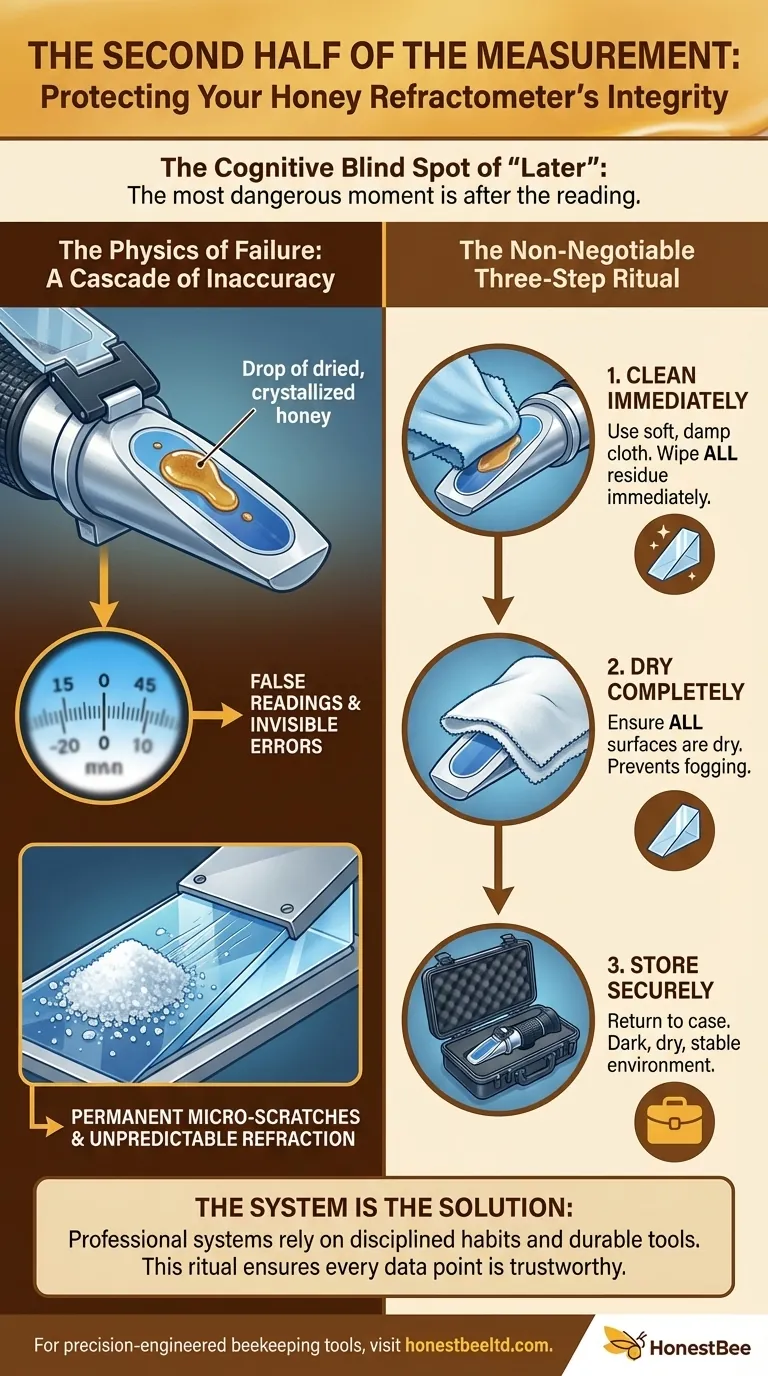

The Physics of Failure: A Cascade of Inaccuracy

Failure to properly care for a refractometer isn't a single event. It's a cascade that begins with a simple mistake and ends with a permanently compromised tool.

From Residue to False Readings

Dried honey residue left on the prism alters the refractive index for the next sample. It creates a false baseline. Your next reading won't be a measurement of the new honey sample alone, but a contaminated reading of the new sample plus the old, crystallized residue.

This introduces an invisible error into your entire quality control process. You might believe a batch is stable when it's not, or vice versa, leading to flawed decisions about storage, blending, or sales.

From Crystals to Scratches

Hardened sugar crystals are incredibly abrasive. If you close the cover plate onto a dirty prism or attempt to scrape off old, dried honey, you are essentially grinding a mineral against a delicate optical surface.

This will cause permanent micro-scratches on the prism. These scratches don't just get dirty; they refract light unpredictably, destroying the instrument's ability to give a clear, accurate reading. The damage is irreparable.

The Non-Negotiable Three-Step Ritual

To prevent this cascade, the post-measurement process must become a non-negotiable ritual. It’s not just "cleaning"; it's a systematic preservation of accuracy.

-

Clean Immediately: Use a soft, damp, lint-free cloth to gently wipe all honey from the prism and the underside of the cover plate. Do this the moment you finish your reading, before the sugar has any time to set. Never use paper towels or a rough cloth.

-

Dry Completely: Use a dry part of the cloth to remove every trace of moisture. Storing the instrument while damp can lead to condensation fogging the internal optics, especially with temperature changes.

-

Store Securely: Always return the refractometer to its protective case. Store that case in a dark, dry environment with a stable temperature—not in a truck or a hot honey house. This shields it from physical shock, dust, and environmental damage.

The Workflow at a Glance

| Step | Action | Why It's Critical |

|---|---|---|

| 1. Clean | Wipe prism & cover with a damp, lint-free cloth. | Prevents dried honey from causing false readings or scratches. |

| 2. Dry | Ensure all surfaces are completely dry with a soft cloth. | Stops moisture damage, condensation, and mold growth. |

| 3. Store | Place in protective case in a dark, dry location. | Shields from physical shock, dust, and environmental damage. |

The System is the Solution

Professional results depend on professional systems, and professional systems rely on disciplined habits and durable tools. Treating your refractometer with this level of care is not a chore; it is an affirmation of your commitment to quality. It ensures that every single data point you collect is trustworthy.

For commercial apiaries and distributors, where consistency is paramount, this discipline is the foundation of brand reputation. It requires equipment built to withstand the rigors of daily, professional use. At HONESTBEE, we supply the robust, precision-engineered beekeeping tools that professionals rely on. We understand that the best equipment is that which supports and rewards meticulous care.

The integrity of your honey is a direct reflection of the integrity of your process. Ensure both are flawless. Contact Our Experts to equip your operation with supplies built for professional standards.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

Related Articles

- From Ambiguity to Certainty: The Practical Case for Digital Honey Refractometers

- How to Perfect Honey Moisture Levels: A Beekeeper’s Guide to Refractometer Mastery

- Mastering Honey Refractometer Basics: A Guide to Precision and Profitability

- How to Accurately Test Honey Readiness: Science-Backed Methods for Beekeepers

- From Profit to Spoilage: The One Number Every Commercial Beekeeper Must Know