Beekeepers know that hive tools are the unsung heroes of apiary maintenance—when used correctly, they can dramatically improve efficiency while protecting colony health. This guide reveals professional techniques to maximize your tool's effectiveness without compromising hive integrity.

Essential Hive Tool Functions

Prioritizing High-Impact Maintenance Tasks

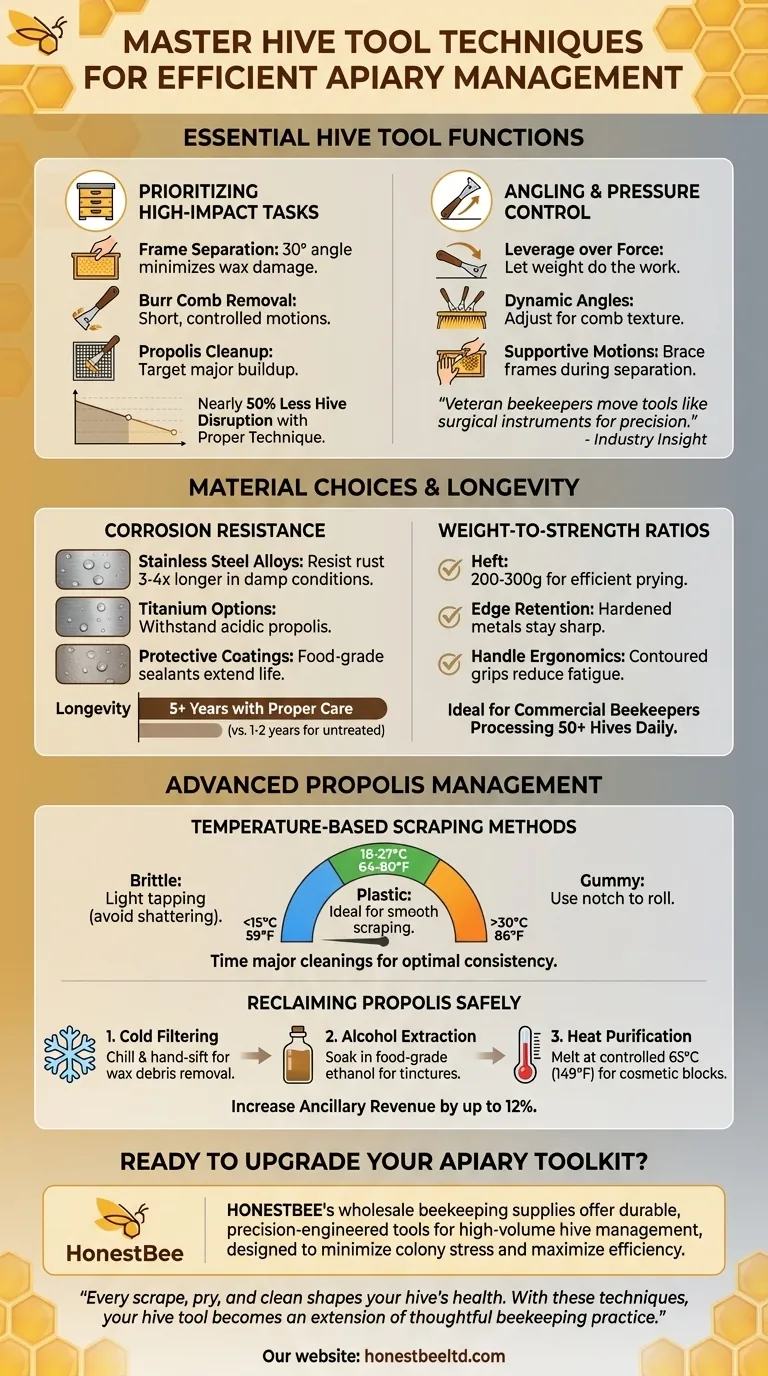

Focus your hive tool on tasks where it delivers the most value:

- Frame separation: Insert the tool at a 30° angle between boxes to minimize wax damage

- Burr comb removal: Use the scraper edge in short, controlled motions

- Propolis cleanup: Target major buildup points near frame rests and queen excluders

Research shows proper technique reduces hive disruption by nearly half compared to haphazard scraping.

Angling and Pressure Control for Delicate Components

The key to preserving comb integrity lies in:

- Leverage over force: Let the tool's weight do the work—excessive pressure crushes brood cells

- Dynamic angles: Adjust your scraping angle based on comb texture (e.g., steeper for crystallized propolis)

- Supportive motions: Brace frames with your free hand during separation

"Have you noticed how veteran beekeepers move their tools like surgical instruments? That precision comes from understanding pressure distribution."

Material Choices and Longevity

Corrosion Resistance in Humid Environments

When selecting hive tools, consider:

- Stainless steel alloys: Resist rust 3-4x longer than carbon steel in damp conditions

- Titanium options: Though costlier, they withstand acidic propolis corrosion exceptionally well

- Protective coatings: Some brands apply food-grade sealants that extend tool life

Humid apiaries report tools lasting 5+ years with proper care versus 1-2 years for untreated metals.

Weight-to-Strength Ratios for Prolonged Use

The ideal tool balances:

✔ Heft: Enough mass for efficient prying (200-300g range)

✔ Edge retention: Hardened metals stay sharp through hundreds of hive inspections

✔ Handle ergonomics: Contoured grips reduce hand fatigue during marathon sessions

Commercial beekeepers processing 50+ hives daily should prioritize these durability factors.

Advanced Propolis Management

Temperature-Based Scraping Methods

Propolis becomes:

- Brittle below 15°C (59°F): Requires light, tapping motions to avoid shattering

- Plastic between 18-27°C (64-80°F): Ideal for smooth scraping

- Gummy above 30°C (86°F): Use the tool's notch to roll rather than scrape

Seasoned apiarists time major cleanings to mid-morning when temperatures optimize propolis consistency.

Reclaiming Propolis Safely for Reuse

Transform scraped propolis into valuable byproducts by:

- Cold filtering: Remove wax debris by chilling then hand-sifting

- Alcohol extraction: Soak clean propolis in food-grade ethanol for tinctures

- Heat purification: Melt at controlled 65°C (149°F) for cosmetic-grade blocks

One commercial operation increased ancillary revenue by 12% through systematic propolis recovery.

Ready to upgrade your apiary toolkit? HONESTBEE's wholesale beekeeping supplies give commercial operators the durable, precision-engineered tools needed for high-volume hive management—all designed to minimize colony stress while maximizing your efficiency.

Every scrape, pry, and clean shapes your hive's health. With these techniques, your hive tool becomes an extension of thoughtful beekeeping practice.

Visual Guide

Related Products

- Multi-Function Hive Tool with Integrated Hammer for Beekeeping

- Wooden Bee Brush with Triple Row Artificial Fiber for Beekeeping

- Ergonomic Two Person Foldable Hive Lifter

- Professional Drop-Style Hive Handles for Beekeeping

- Ergonomic High Visibility Plastic Frame Grip Handles

Related Articles

- Beyond the Pry Bar: The Physics and Psychology of the J-Hook Hive Tool

- Engineering for Propolis: The Physics and Psychology of the Right Hive Tool

- The Gentle Art of Leverage: Why Your Hive Tool Isn't a Crowbar

- A Beekeeper's Oath: The Biosecurity and Ethics Engineered into a Bee Brush

- More Than Steel: How a Simple Hive Tool Dictates the Success of an Apiary