Beeswax processing requires precise thermal control to preserve product integrity while maximizing operational efficiency. For commercial apiaries and equipment distributors, understanding these technical nuances directly impacts product quality and profitability. This guide examines critical wax melting parameters, equipment selection strategies, and best practices for industrial-scale operations.

Beeswax Preparation Fundamentals

Thermal Properties of Beeswax

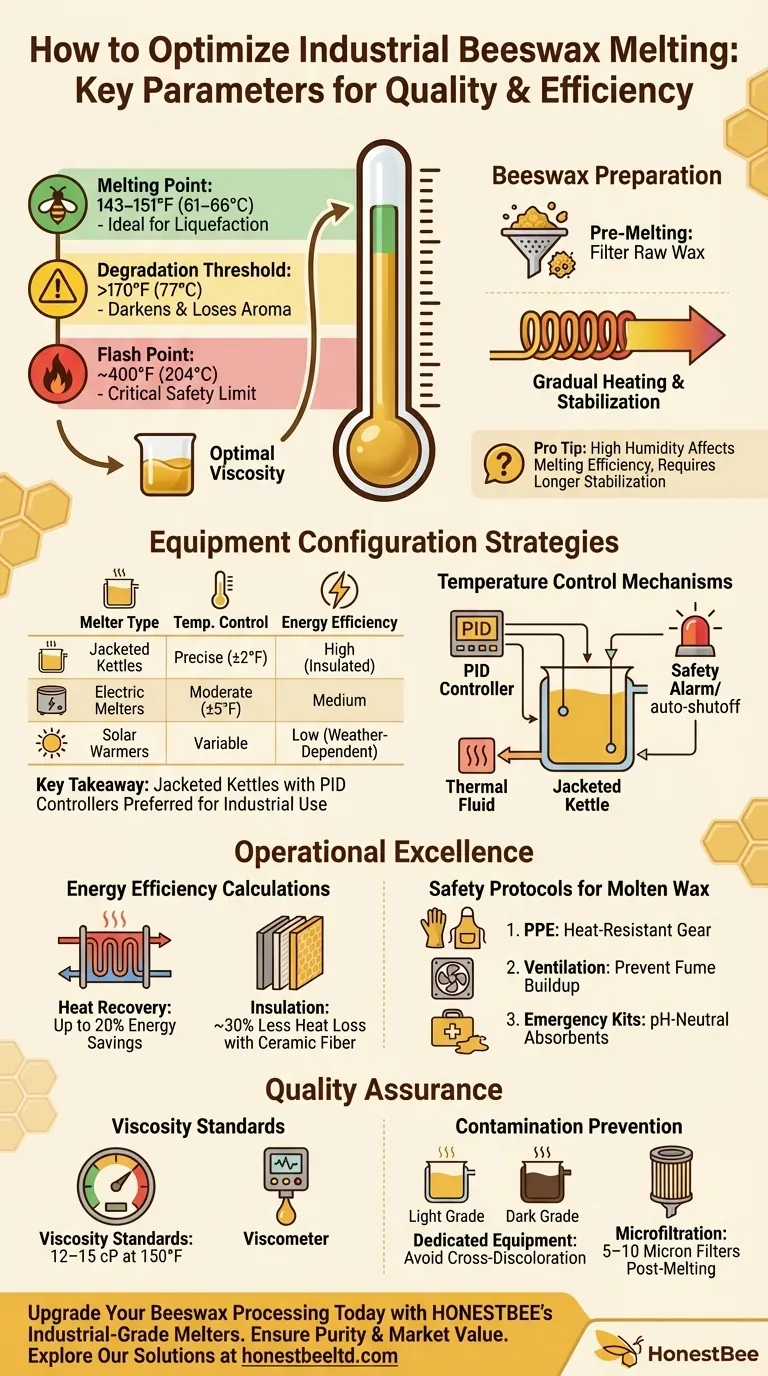

Beeswax undergoes distinct phase transitions that dictate processing conditions:

- Melting Point: 143–151°F (61–66°C) — The ideal range for liquefaction without compromising quality.

- Degradation Threshold: Beyond 170°F (77°C), wax darkens and loses aromatic compounds, reducing market value.

- Flash Point: ~400°F (204°C) — Critical for safety protocols in high-volume operations.

Research shows that maintaining temperatures within the 143–151°F window ensures optimal viscosity for downstream applications like embossing or candle molding.

Phase Transition Requirements

- Pre-Melting Preparation: Filter raw wax to remove hive debris (e.g., propolis or pollen).

- Gradual Heating: Avoid direct high heat to prevent localized overheating.

- Stabilization: Use agitation to ensure even heat distribution during melting.

Pro Tip: Have you considered how ambient humidity affects melting efficiency? In high-moisture environments, wax may require longer stabilization times to achieve uniform consistency.

Equipment Configuration Strategies

Wax Melter Types Comparison

| Type | Best For | Temperature Control | Energy Efficiency |

|---|---|---|---|

| Jacketed Kettles | Large batches (>500 lbs) | Precise (±2°F) | High (insulated) |

| Electric Melters | Medium-scale operations | Moderate (±5°F) | Medium |

| Solar Warmers | Eco-conscious processing | Variable | Low (weather-dependent) |

Key Takeaway: Jacketed kettles with PID controllers are preferred for industrial settings, minimizing thermal fluctuations that risk degradation.

Temperature Control Mechanisms

- PID Controllers: Automatically adjust heating elements to maintain ±2°F accuracy.

- Thermal Fluid Systems: Use food-grade oils for indirect heating, reducing hot spots.

- Alarms & Auto-Shutoff: Mandatory for safety when wax approaches 170°F.

Operational Excellence

Energy Efficiency Calculations

- Heat Recovery: Up to 20% energy savings by recycling waste heat from cooling phases.

- Insulation: High-grade ceramic fiber reduces heat loss by ~30% compared to standard materials.

Safety Protocols for Molten Wax

- Personal Protective Equipment (PPE): Heat-resistant gloves and aprons.

- Ventilation: Prevent vapor buildup (beeswax fumes can irritate respiratory systems).

- Emergency Kits: Include pH-neutral spill absorbents for accidental releases.

Quality Assurance

Viscosity Standards for Embossing

- Target Range: 12–15 cP at 150°F — Achieved through controlled cooling rates.

- Testing: Rotational viscometers verify consistency batch-to-batch.

Contamination Prevention Methods

- Dedicated Equipment: Separate melters for light/dark wax grades avoid cross-discoloration.

- Microfiltration: 5–10 micron filters remove particulates post-melting.

Upgrade Your Beeswax Processing Today

For commercial apiaries and distributors, HONESTBEE’s industrial-grade wax melters combine precision temperature control with robust safety features—ensuring your beeswax retains its purity and market value. Explore our solutions to streamline your production.

Final Thought: Like the bees that produce it, beeswax thrives under carefully balanced conditions. Modern melting technologies are the unseen backbone of quality wax products, from cosmetics to pharmaceuticals.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

Related Articles

- How to Optimize Steam Wax Melting for Higher Yields and Safer Operations

- How to Clean Beeswax Properly: A Step-by-Step Guide to Preserving Quality

- How Beekeepers Turn Old Beeswax into Profitable Ventures

- How to Purify Beeswax Contaminated with Brood Comb: Maximizing Honey Recovery

- The Unseen Engine of the Hive: Decoding the Economics of Wax Production