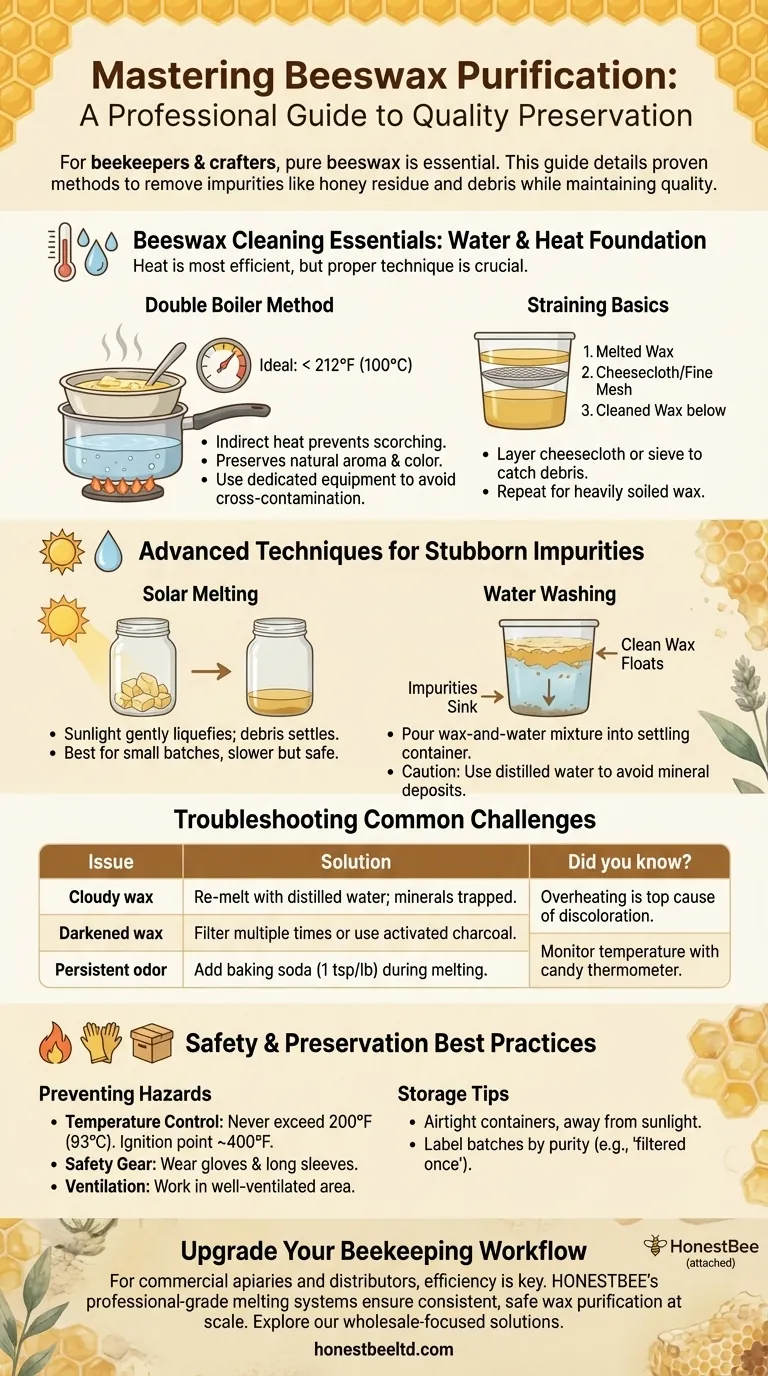

For beekeepers and crafters, beeswax is a valuable resource—but impurities like honey residue, pollen, or debris can compromise its usability. Cleaning beeswax effectively requires balancing thorough purification with safety measures to maintain its natural benefits. This guide covers proven methods to achieve pure, reusable beeswax while avoiding common pitfalls.

Beeswax Cleaning Essentials

Why Water and Heat Are the Foundation of Purification

Beeswax melts at around 145°F (63°C), making heat the most efficient way to separate impurities. However, improper heating can degrade wax quality or pose fire risks. Here’s how to do it right:

-

Double Boiler Method:

- Indirect heat prevents scorching. A water bath keeps temperatures stable, ideally below 212°F (100°C).

- Research shows this method preserves wax’s natural aroma and color better than direct heat.

- Tip: Use a dedicated boiler to avoid cross-contamination with food-grade equipment.

-

Straining Basics:

- Layer cheesecloth or a fine mesh sieve over your melting container to catch debris.

- For heavily soiled wax, repeat straining with progressively finer filters.

Advanced Techniques for Stubborn Impurities

Some contaminants, like propolis or dark discoloration, require extra steps:

-

Solar Melting:

- Place wax in a glass jar or solar melter. Sunlight gently liquefies wax while letting debris settle.

- Best for small batches; slower but avoids overheating.

-

Water Washing:

- After melting, pour wax-and-water mixtures into a settling container. Impurities sink or float for easy removal.

- Caution: Hard water can leave mineral deposits; distilled water is preferable.

Troubleshooting Common Cleaning Challenges

| Issue | Solution |

|---|---|

| Cloudy wax | Re-melt with distilled water; minerals may be trapped. |

| Darkened wax | Filter multiple times or use activated charcoal (food-grade). |

| Persistent odor | Add baking soda during melting (1 tsp per pound of wax). |

Did you know? Overheating is the top cause of discoloration. Monitoring temperature with a candy thermometer helps maintain optimal conditions.

Safety and Preservation Best Practices

Preventing Hazards

- Temperature Control: Never exceed 200°F (93°C). Beeswax ignites around 400°F (204°C).

- Safety Gear: Wear gloves and long sleeves to protect against splashes.

- Ventilation: Work in a well-ventilated area to avoid fume buildup.

Storage Tips

- Keep cleaned wax in airtight containers away from sunlight to prevent brittleness.

- Label batches by purity level (e.g., “filtered once” vs. “double-filtered”).

Upgrade Your Beekeeping Workflow with HONESTBEE

For commercial apiaries and distributors, efficiency is key. HONESTBEE’s professional-grade melting systems ensure consistent, safe wax purification at scale. Explore our wholesale-focused solutions to streamline your process—because pure wax starts with the right tools.

Final Thought: Clean beeswax isn’t just about removing dirt; it’s about preserving a natural material that supports sustainable crafting and beekeeping alike. With these methods, you’ll extend its lifespan while safeguarding quality.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Professional Thermostatic Conical Honey Melter

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

Related Articles

- How to Optimize Industrial Beeswax Melting: Key Parameters for Quality & Efficiency

- How Beekeepers Turn Wax Cappings From Waste to Profit

- How to Purify Beeswax Contaminated with Brood Comb: Maximizing Honey Recovery

- How Beekeepers Turn Old Beeswax into Profitable Ventures

- The Unseen Engine of the Hive: Decoding the Economics of Wax Production