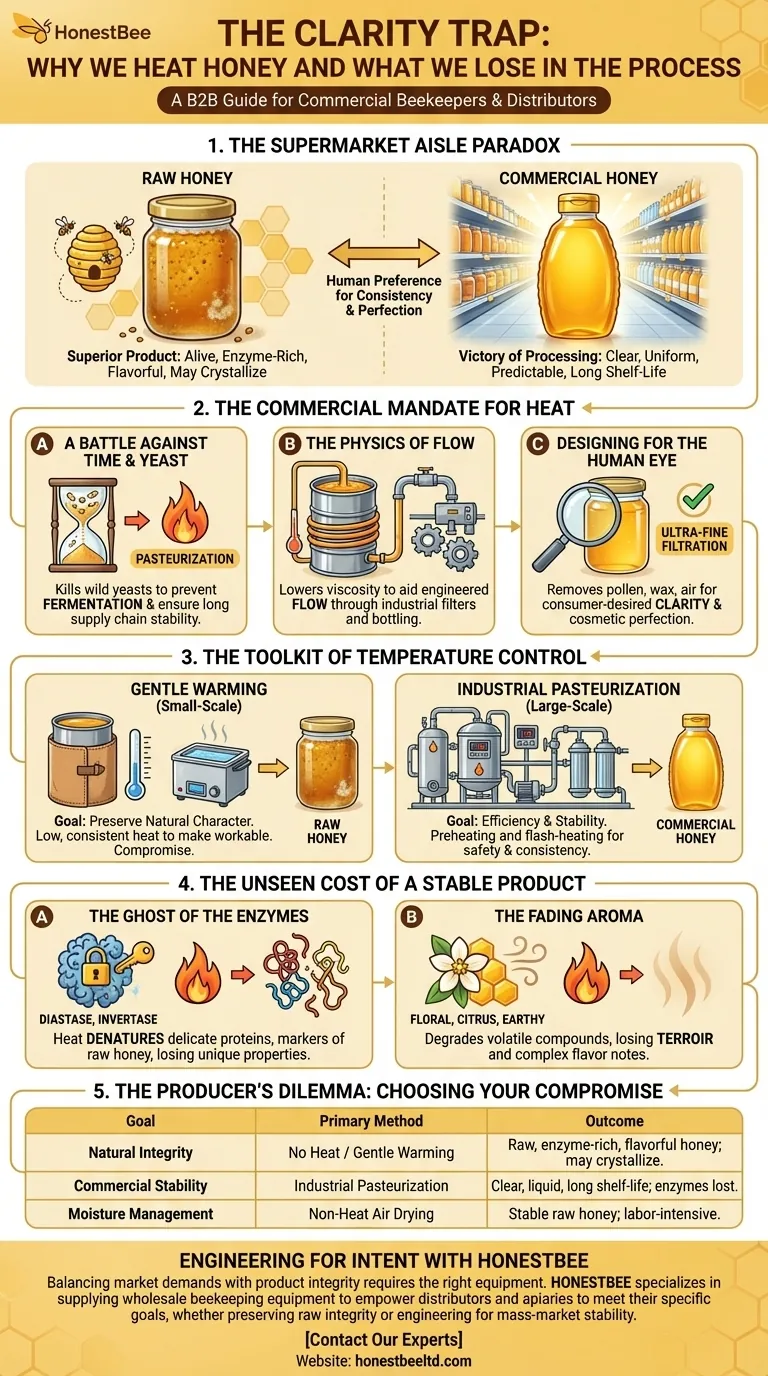

The Supermarket Aisle Paradox

Picture a commercial beekeeper standing in a supermarket aisle. Before them are rows of honey, each bottle a perfect, glowing amber. The liquid is flawlessly clear, uniform, and flows with predictable grace.

They know what this image represents: a victory of industrial processing. They also know it’s a paradox.

The honey they harvested this morning—thick, occasionally cloudy with pollen, and already showing the first signs of crystallization—is, by many measures, a superior product. Yet, it would likely fail the modern consumer's visual test.

The journey from the hive to that pristine bottle is a story of heat, pressure, and filtration. It’s a process born not from a need to improve the honey, but from a need to solve a fundamentally human problem: our deep-seated psychological preference for consistency and cosmetic perfection.

The Commercial Mandate for Heat

The decision to heat honey isn't arbitrary; it's a calculated response to the challenges of time, physics, and consumer perception. For any large-scale operation, it’s practically a requirement.

A Battle Against Time and Yeast

Raw honey is alive. It contains wild yeasts that, given enough moisture, will begin to ferment. For a product that must endure a long supply chain and sit on a shelf for months, fermentation is a fatal flaw.

Pasteurization—the rapid application of high heat—is the industry's insurance policy. It kills these yeasts, creating a biologically stable product with a dramatically extended shelf life.

The Physics of Flow

Honey is notoriously viscous. On a cold morning, it can be as stubborn as concrete. For a commercial operation that needs to move thousands of gallons from drums, through pipes, into filters, and finally into bottles, this is an engineering nightmare.

Gently heating the honey lowers its viscosity, making it pliable. This isn't about changing its essence, but simply making it cooperate with the machinery of modern production.

Designing for the Human Eye

We buy with our eyes. Consumers have been conditioned to associate clarity with purity and crystallization with spoilage. Heat, combined with ultra-fine filtration, removes every last particle of pollen, wax, and even tiny air bubbles that might mar its crystal-clear appearance.

The goal is to produce a honey that looks identical in July and December, whether it was bought in Texas or Maine.

The Toolkit of Temperature Control

The methods for applying this heat are as varied as the goals of the producers themselves. The choice of tool reveals the operator's philosophy—a delicate balance between preservation and processability.

- Gentle Warming: For small-scale apiaries or producers of "raw" honey, water bath heaters or electric drum blankets are the tools of choice. They apply low, consistent heat, just enough to make the honey workable for bottling without "cooking" it. This is a compromise aimed at preserving the honey’s natural character.

- Industrial Pasteurization: In large-scale plants, the process is far more intense. Preheating systems make the honey flow for filtration, followed by flash-heating in a pasteurizer to ensure stability. This system prioritizes efficiency, safety, and consistency above all else.

This is the core dilemma for every honey business: which path do you choose? The answer dictates your equipment needs, your market, and the very nature of your final product.

The Unseen Cost of a Stable Product

Creating that perfectly stable, visually appealing honey comes at a price—one that isn't listed on the label. Heat, for all its practical benefits, fundamentally alters the honey's composition.

The Ghost of the Enzymes

The most significant loss is the destruction of natural enzymes like diastase and invertase. These delicate proteins, which bees add to nectar, are markers of raw, unprocessed honey and are believed to contribute to its unique properties. High heat denatures them, effectively turning a complex, living food into a simple, sterile sweetener.

The Fading Aroma

Heat also degrades the volatile compounds that give honey its soul. The subtle floral notes from a field of clover, the citrusy aroma of orange blossom honey, the rich scent of buckwheat—these are the first casualties of high temperatures. The result is often a more generic, sometimes slightly caramelized flavor that lacks the terroir of its origin.

The Producer's Dilemma: Choosing Your Compromise

The decision to heat honey is not a question of right or wrong. It's an engineering and business choice based on a clear-eyed assessment of priorities.

| Goal | Primary Method | Outcome |

|---|---|---|

| Natural Integrity | No Heat / Gentle Warming | Raw, enzyme-rich, flavorful honey; may crystallize. |

| Commercial Stability | Industrial Pasteurization | Clear, liquid, long shelf-life; enzymes lost. |

| Moisture Management | Non-Heat Air Drying | Stable raw honey; labor-intensive. |

Ultimately, honey processing is an act of engineering for intent. A commercial producer’s challenge is to balance the demands of the market with the integrity of the product. That requires not just skill, but the right equipment to execute their vision flawlessly.

Whether your operation is built around preserving the raw integrity of your harvest or engineering for mass-market stability, having reliable, commercial-grade equipment is the foundation of your success. HONESTBEE specializes in supplying the wholesale beekeeping equipment that empowers distributors and apiaries to meet their specific goals. Contact Our Experts

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

Related Articles

- How to Prevent and Manage Honey Crystallization in Flow Hives: A Beekeeper’s Guide

- How Honey Processing Affects Nutrition: Science-Backed Insights for Healthier Choices

- How Bee Behavior and Weather Dictate Optimal Honey Harvest Times

- Heat, Honey, and Haste: The Physics of Preserving Liquid Gold

- How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines