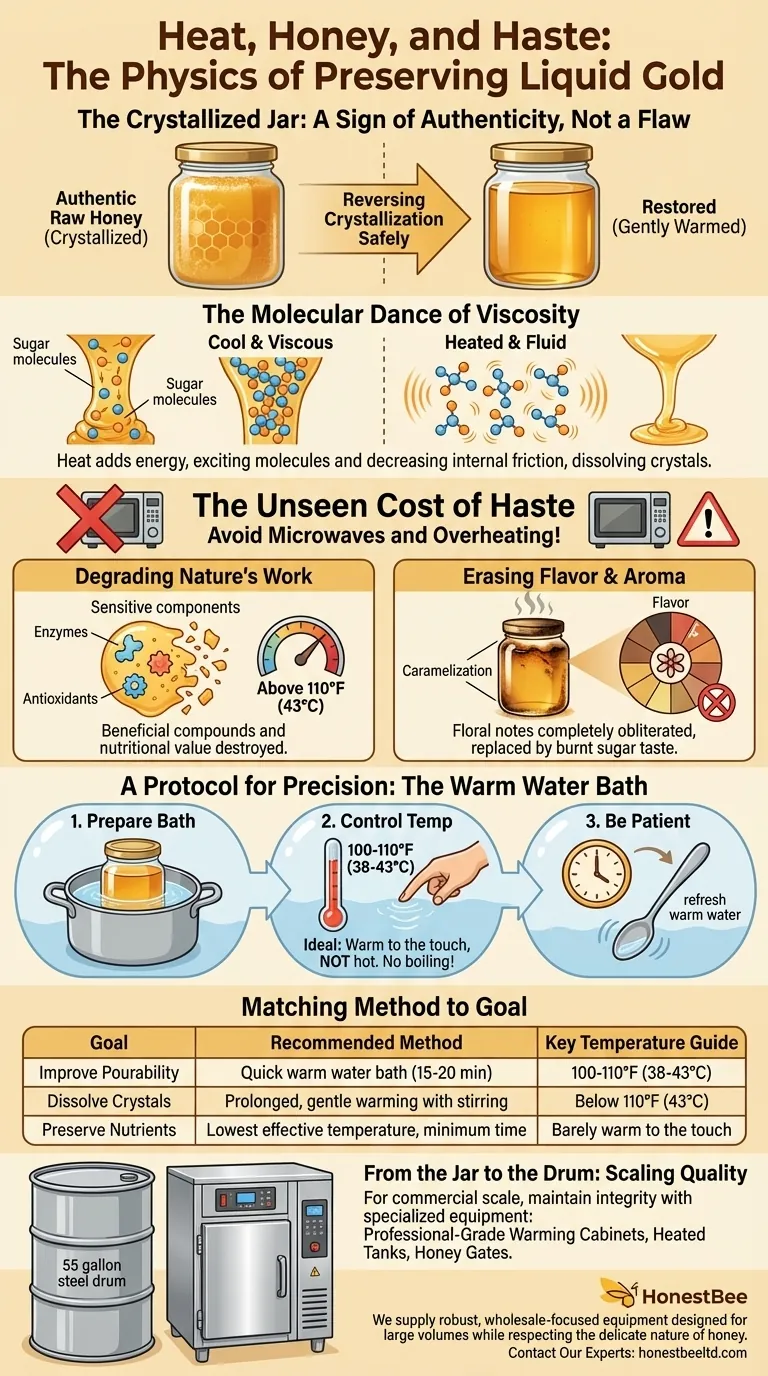

The Crystallized Jar: A Sign of Authenticity, Not a Flaw

Every beekeeper, distributor, and honey lover has faced it: a jar of honey, once clear and flowing, has turned solid and opaque.

Our first instinct is often one of frustration. We see it as a product that has gone bad. But this is a fundamental misunderstanding. Crystallization isn't a sign of spoilage; it's a hallmark of raw, authentic honey. The glucose, a primary sugar, has simply separated from the water.

The real challenge isn't the crystallization itself, but how we choose to reverse it. The path we take determines whether we restore the honey to its liquid glory or irrevocably damage it.

The Molecular Dance of Viscosity

Honey's thickness, its viscosity, is a measure of its internal friction. In its cool, natural state, the sugar molecules are densely packed and move sluggishly, creating that wonderful, slow drizzle.

Applying heat is applying energy. This energy excites the molecules, causing them to vibrate, move faster, and spread further apart. The internal friction decreases, and the viscosity drops.

Simultaneously, this energy gently dissolves the glucose crystals, reintegrating them into the solution. The honey becomes fluid and clear once more. It’s a simple, elegant process of physics.

The Unseen Cost of Haste

The most common mistake is born from impatience. We want a quick fix, so we apply too much heat, too quickly. This is where restoration turns into destruction.

The temptation to use a microwave is a perfect example. It's a siren's call for efficiency that leads directly to ruin. Microwaves heat unevenly and aggressively, creating "hot spots" that essentially boil the honey, scorching its sugars and destroying its delicate structure.

Degrading Nature's Work

Raw honey is more than just sugar. It contains a complex profile of enzymes and antioxidants, compounds that are incredibly sensitive to heat.

Once temperatures rise above 110°F (43°C), these beneficial components begin to break down. The nutritional value that makes honey a unique natural product is the first casualty of excessive heat.

Erasing Flavor and Aroma

The damage doesn't stop at the molecular level; it extends to the sensory experience. Overheating caramelizes the honey's sugars.

This process darkens the color and, more critically, obliterates the nuanced floral notes that tell the story of its origin. A delicate clover or orange blossom honey can be transformed into something with a generic, burnt-sugar taste. The change is permanent.

A Protocol for Precision: The Warm Water Bath

The goal is to warm the honey, not to cook it. This requires gentle, indirect heat. The warm water bath is the gold standard for this principle.

- Prepare the Bath: Place the honey container (preferably glass) into a larger pot. Fill the pot with warm water, ensuring the water level is below the lid.

- Control the Temperature: The ideal temperature is between 100-110°F (38-43°C). It should feel warm to the touch, not hot. Boiling water is a guarantee of damage.

- Be Patient: Allow the jar to sit. Stirring gently every 20-30 minutes will help distribute the warmth evenly. Heavy crystallization may require refreshing the warm water and waiting longer.

This simple protocol respects the delicate nature of the product.

Matching Method to Goal

Your specific approach depends on your objective. The principles remain the same, but the variables of time and temperature are adjusted accordingly.

| Goal | Recommended Method | Key Temperature Guide |

|---|---|---|

| Improve Pourability | Quick warm water bath (15-20 min) | 100-110°F (38-43°C) |

| Dissolve Crystals | Prolonged, gentle warming with stirring | Below 110°F (43°C) |

| Preserve Nutrients | Lowest effective temperature, minimum time | Barely warm to the touch |

From the Jar to the Drum: Scaling Quality

This principle of gentle thermal management scales directly from a single jar on a kitchen counter to a 55-gallon drum in a commercial apiary. The challenge, however, becomes magnified. You can't place a drum in a sink of warm water.

For commercial operators and distributors, managing viscosity and crystallization is a critical operational bottleneck. Inefficient or improper heating leads to product degradation, lost time, and reduced value.

Maintaining the integrity of hundreds or thousands of pounds of honey requires specialized equipment built on the same principle: gentle, consistent, and controllable heat. This is where professional-grade warming cabinets, heated tanks, and honey gates become essential tools, not luxuries. They are the instruments that allow you to manage honey's physical state without compromising the quality your customers expect.

At HONESTBEE, we understand that your product's value is tied to its quality. We supply the robust, wholesale-focused equipment designed to handle large volumes while respecting the delicate nature of honey. Contact Our Experts

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

Related Articles

- How to Optimize Steam Wax Melting for Higher Yields and Safer Operations

- The Unseen Cost of Manual Honey Filling: A Case for Automation

- How Honey Heating Tanks Preserve Quality and Efficiency in Modern Beekeeping

- How to Prevent and Manage Honey Crystallization in Flow Hives: A Beekeeper’s Guide

- How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines