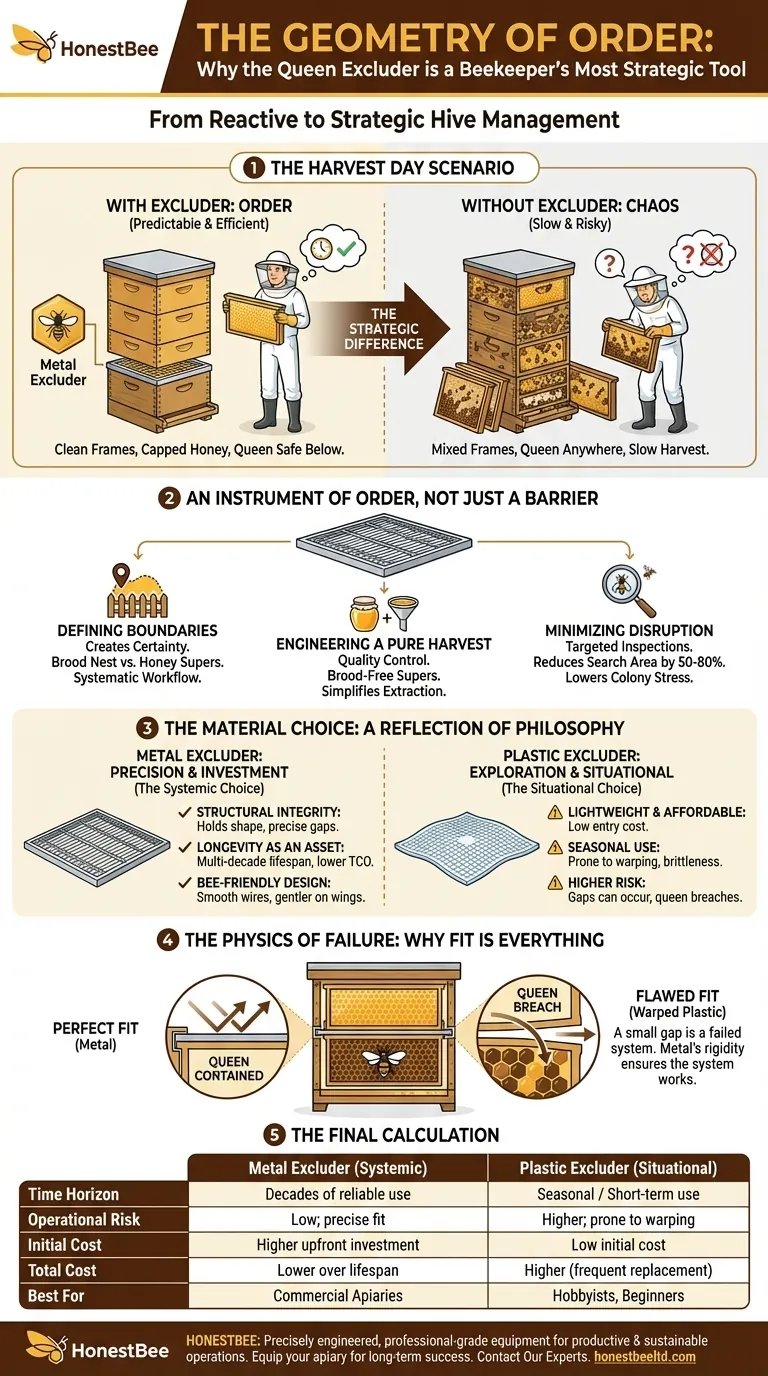

The Harvest Day Scenario

Picture two scenarios on a warm afternoon, sun high in the sky, the air thick with the smell of honey.

In the first, a beekeeper lifts a heavy honey super. Every frame is clean, filled with capped honey. The process is calm, efficient, and predictable. The honey is pure, the brood is safe below, and the queen's location is known.

In the second, the beekeeper lifts a super to find a chaotic mix of honey, pollen, eggs, and larvae. The queen could be anywhere. Every frame becomes a delicate puzzle, slowing the harvest and risking the queen's safety.

The difference between these two worlds isn't luck. It's a single, simple piece of equipment: the queen excluder.

An Instrument of Order, Not Just a Barrier

We often describe the queen excluder by what it does: it keeps the queen in the brood chamber. But its true function is psychological and systemic. It imposes a deliberate order on a complex natural system, transforming hive management from reactive to strategic.

Defining Boundaries for Predictable Workflows

By confining the queen, you create certainty. The brood nest has a defined territory. The honey supers have a single purpose. This separation of concerns is the foundation of efficient commercial beekeeping. It allows for systematic work, box by box, without constant re-evaluation.

Engineering a Pure Harvest

A queen excluder is a tool for quality control. It guarantees that frames in the honey supers are free of brood and their associated shed skins. This simplifies extraction immensely, ensuring the final product is nothing but pure honey.

Minimizing Disruption, Maximizing Focus

When you need to find the queen, an excluder reduces your search area by 50-80%. You aren't rummaging through an entire colony, spreading alarm and chilling brood. You are making a targeted, surgical inspection. This saves time, reduces colony stress, and lowers the cognitive load on the beekeeper.

The Material Choice: A Reflection of Your Philosophy

The decision between a metal and a plastic excluder is more than a matter of budget. It’s a statement about your operational philosophy: are you solving a problem for this season, or are you building a system for the next decade?

Metal: An Investment in Precision

Welded-wire metal excluders, made of stainless or galvanized steel, are the professional standard for a reason. Their value isn't just in their durability; it's in their consistency.

- Structural Integrity: Metal holds its shape. It doesn't warp in the summer heat or become brittle in the cold. This ensures the gap size remains precise, year after year.

- Longevity as an Asset: A metal excluder isn't an expense; it's a long-term capital investment. Its multi-decade lifespan provides a lower total cost of ownership for any serious operation.

- Bee-Friendly Design: The smooth, rounded wires are thought to be gentler on the delicate wings of worker bees, who may pass through the barrier thousands of times a day.

For commercial apiaries, where equipment failure at scale is not an option, the reliability of metal is non-negotiable.

Plastic: The Tool for Exploration

Plastic excluders are lightweight and affordable. They provide an excellent, low-risk entry point for new beekeepers or those managing a small number of hives. They perform the basic function well, but they come with a known set of trade-offs regarding long-term performance.

The Physics of Failure: Why Fit is Everything

An excluder with even a small flaw is a failed system. The most critical factor, beyond material, is a perfect fit.

If gaps exist between the edge of the excluder and the hive body, the queen will find them. When this happens, the entire purpose of the tool is negated. The order you sought to create collapses.

This is where metal's resistance to warping provides a crucial advantage. A plastic excluder that bows slightly in the center or lifts at a corner creates a breach. A rigid metal excluder maintains a tight, reliable seal, ensuring the system works as designed.

The Final Calculation

Your choice comes down to a simple set of priorities. There is no single "best" excluder, only the one that best aligns with the scale and ambition of your operation.

| Factor | Metal Excluder (The Systemic Choice) | Plastic Excluder (The Situational Choice) |

|---|---|---|

| Time Horizon | Built for decades of reliable use | Designed for seasonal or short-term use |

| Operational Risk | Low; maintains precise fit and integrity | Higher; prone to warping, brittleness, gaps |

| Initial Cost | Higher upfront investment | Low initial cost |

| Total Cost | Lower over the lifespan of the apiary | Higher due to frequent replacement |

| Best For | Commercial apiaries, long-term beekeepers | Hobbyists, beginners, tight budgets |

For operations where efficiency, predictability, and durability directly impact the bottom line, the choice becomes an engineering decision. You choose the tool that won't fail.

HONESTBEE is dedicated to supplying commercial apiaries and distributors with precisely engineered, professional-grade beekeeping equipment. Our focus is on providing durable, reliable tools like welded-wire queen excluders that form the backbone of a productive and sustainable operation.

Equip your apiary for long-term success. Contact Our Experts

Visual Guide

Related Products

- Professional Plastic Queen Excluder for Modern Beekeeping

- Wooden Queen Bee Excluder for Beekeeping

- Metal Queen Bee Excluder for Beekeeping

- Premium Wood Framed Metal Wire Queen Bee Excluder

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

Related Articles

- How to Choose Queen Excluder Materials for Healthier Hives and Higher Yields

- Galvanized vs. Stainless Steel Queen Excluders: A Data-Backed Guide to Long-Term Durability and Cost Efficiency

- How Queen Excluders Optimize Hive Management: A Beekeeper’s Guide

- Why Plastic Queen Excluders Outperform Metal and Wood: Science, Savings, and Hive Protection

- Beyond the Gate: The Queen Excluder as a Keystone of Apiary Efficiency