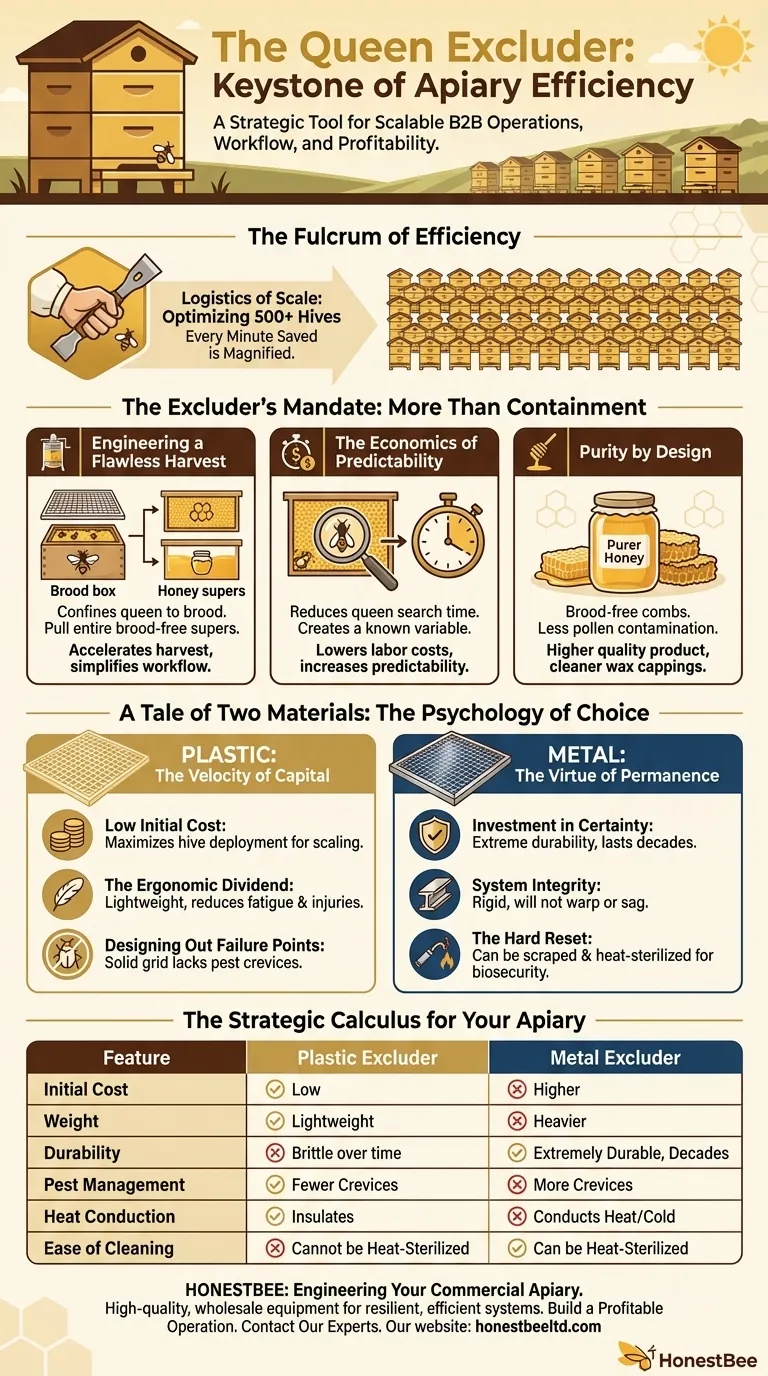

The Fulcrum of Efficiency

Imagine a commercial beekeeper at dawn, looking out over a yard of 500 hives. The air hums with potential. But the primary challenge isn't biology; it's logistics. Every minute saved, every ounce of effort conserved, is magnified five hundred times.

In this world of scaled operations, success is determined by the systems you build. And one of the most critical, yet often overlooked, components of that system is a simple grid of plastic or metal: the queen excluder.

This isn't just a barrier. It's a strategic decision that dictates workflow, influences profitability, and reflects an entire operational philosophy.

The Excluder’s Mandate: More Than Containment

The core function of an excluder is to control the queen's location. But its purpose is to create order and predictability in a complex biological system. This control is the foundation of operational efficiency.

Engineering a Flawless Harvest

By confining the queen to the brood boxes, you guarantee the honey supers above are free of eggs, larvae, and pupae.

This transforms the harvest. Instead of inspecting each frame, operators can pull entire boxes, dramatically accelerating the process. It simplifies clearing bees from the supers and ensures a workflow built on speed and repetition—the hallmarks of a scalable operation.

The Economics of Predictability

Time is the most valuable currency in a commercial apiary. When you need to find the queen for an inspection, a health check, or re-queening, a random search through ten or twenty frames is a costly waste.

An excluder reduces this search time to nearly zero. It creates a known variable in an otherwise unpredictable environment. This isn't just a convenience; it's a direct reduction in labor costs and a psychological relief for the beekeeper.

Purity by Design

Keeping the brood nest separate from honey storage engineers a higher quality product. Brood-free combs mean less pollen contamination, resulting in purer honey that can command a better price.

It also yields cleaner, higher-grade wax from cappings—a valuable secondary product whose quality is determined by the system's design from the start.

A Tale of Two Materials: The Psychology of Choice

The decision between plastic and metal is a classic study in trade-offs. It pits upfront cost against long-term resilience, immediate convenience against permanent reliability. It's a choice about how you value capital, time, and risk.

The Case for Plastic: The Velocity of Capital

Plastic’s undeniable advantage is its low initial cost. For an operation scaling up, this isn't just about being cheap; it's about deploying capital efficiently to maximize the number of productive hives.

But its true elegance lies in two other areas:

- The Ergonomic Dividend: Plastic is lightweight. Over a day of lifting hundreds of honey-laden supers, this reduction in weight translates to less fatigue and fewer injuries. It’s a human-factors design choice that pays dividends in beekeeper longevity.

- Designing Out Failure Points: Many plastic excluders are molded as a solid grid. This design inherently lacks the crevices and joints where pests like small hive beetles can hide and propagate. It's a passive, elegant solution to a persistent problem.

The Case for Metal: The Virtue of Permanence

Metal is an investment in certainty. A steel excluder is a one-time purchase that may outlast the beekeeper. This isn't just durability; it's predictable reliability. It will not fail you during the peak of the nectar flow.

Its strengths are rooted in its physical integrity:

- System Integrity: Metal is rigid. It will not warp under the heat of the sun or sag under the weight of thousands of bees, ensuring the precise spacing is always maintained. The rules of the hive are non-negotiable.

- The Hard Reset: Metal can be scraped clean of wax and propolis with aggressive force. More importantly, it can be sterilized with a blowtorch. This ability to achieve a "hard reset" is critical for disease management and biosecurity, offering a peace of mind that plastic cannot.

The Strategic Calculus for Your Apiary

Your choice isn't just about a material; it's about aligning your equipment with your operational goals. Are you optimizing for rapid growth, absolute durability, or ease of handling?

This table breaks down the decision into its core components:

| Feature | Plastic Excluder | Metal Excluder |

|---|---|---|

| Initial Cost | Low | Higher |

| Weight | Lightweight | Heavier |

| Durability | Can become brittle over time | Extremely durable, lasts decades |

| Pest Management | Fewer crevices for pests | More crevices for pests to hide |

| Heat Conduction | Does not conduct temperature extremes | Conducts heat and cold |

| Ease of Cleaning | Cannot be heat-sterilized | Can be scraped and heat-sterilized |

At HONESTBEE, we understand that commercial beekeeping is an engineering challenge as much as an agricultural one. We supply the high-quality, wholesale equipment that large-scale apiaries and distributors depend on to build resilient, efficient systems.

Choosing the right component is the first step in building a profitable operation. If you think in terms of scale, workflow, and long-term value, we speak the same language. Contact Our Experts

Visual Guide

Related Products

- Professional Plastic Queen Excluder for Modern Beekeeping

- Premium Wood Framed Metal Wire Queen Bee Excluder

- Wooden Queen Bee Excluder for Beekeeping

- Plastic Queen Bee Excluder for Bee Hive Wholesale

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

Related Articles

- Plastic Queen Excluders vs. Alternatives: A Beekeeper’s Guide to Smarter Hive Management

- The Unseen Gatekeeper: Why Queen Excluders Are Non-Negotiable for Flow Hives

- How Queen Excluders Optimize Hive Management: A Beekeeper’s Guide

- How to Choose Queen Excluder Materials for Healthier Hives and Higher Yields

- The Geometry of Order: Why the Queen Excluder is a Beekeeper's Most Strategic Tool