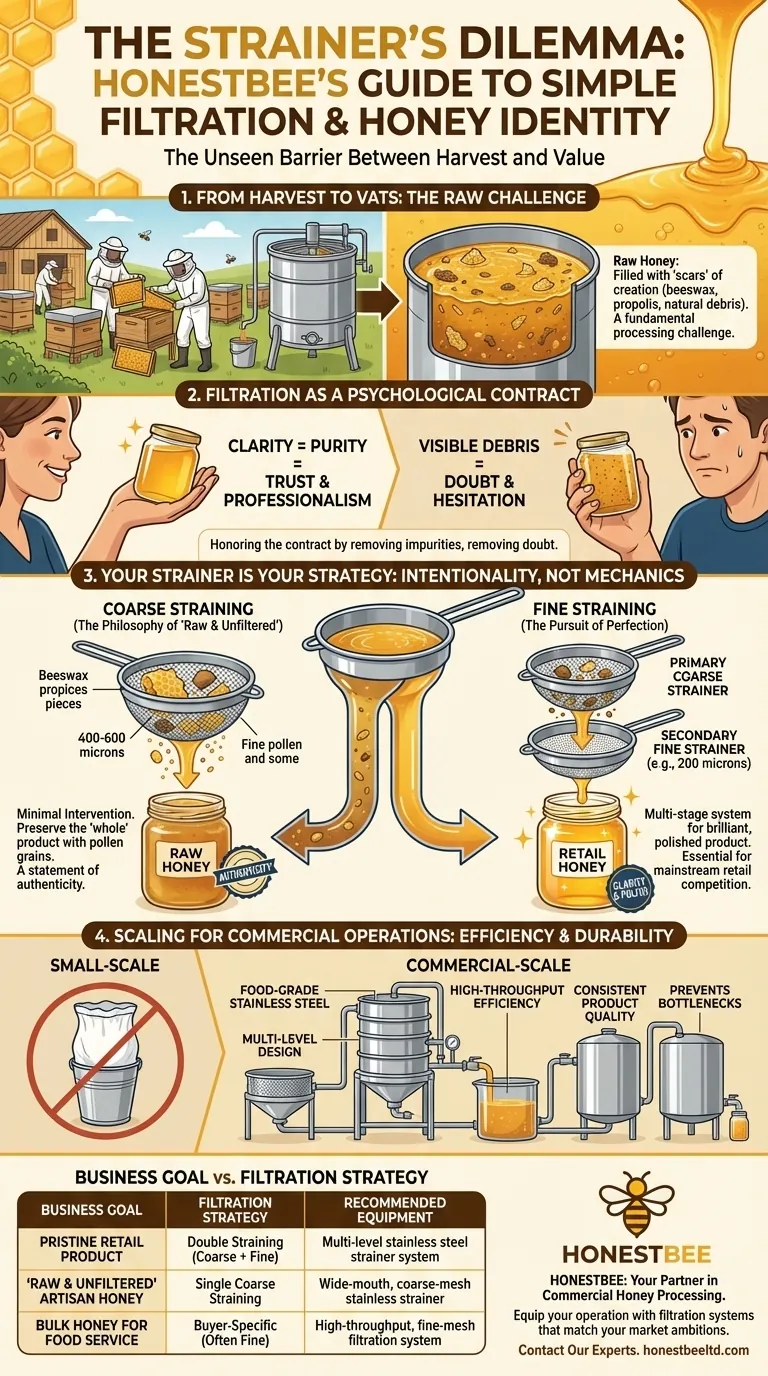

The Unseen Barrier Between Harvest and Value

Imagine the scene: a commercial apiary after a successful harvest. Vats are filled with thousands of pounds of extracted honey—a liquid gold, the culmination of a season's hard work.

But this raw product is not yet the pristine honey that will line a store shelf. It's filled with the "scars" of its creation: tiny flecks of beeswax, bits of propolis, and other fragments from the hive.

This is the fundamental challenge of honey processing. The gap between a raw agricultural product and a trusted consumer good is bridged by a surprisingly simple, yet profoundly important, piece of equipment: the honey strainer.

Filtration as a Psychological Contract

To the consumer, clarity equals purity. This isn't just a preference; it's a deep-seated psychological shortcut.

When a customer holds a jar of honey up to the light, any visible debris, no matter how natural or harmless, can create a moment of hesitation. It subconsciously breaks the trust between producer and consumer. It suggests a lack of care or professionalism.

The primary function of a honey strainer is to honor this psychological contract. By removing physical impurities, it does more than just clean the honey; it removes doubt.

- Beeswax Fragments: The most common debris from the uncapping and extraction process.

- Propolis: A resinous material bees use to seal the hive.

- Wood or Plastic Particles: Tiny splinters from the hive frames.

- Natural Debris: Other hive matter that finds its way into the extractor.

Straining is the first and most critical step in quality control, ensuring the product's visual integrity matches its quality.

A Tool of Intentionality, Not Just Mechanics

A honey strainer is more than a simple filter. It is an instrument of choice, allowing the beekeeper to deliberately define the honey's final character. This choice largely comes down to the mesh size.

The Philosophy of Coarse Straining

For beekeepers marketing "raw" or "unfiltered" honey, filtration is an act of minimal intervention. A coarse strainer (with a larger mesh size, like 400-600 microns) is used with a specific purpose:

- Remove only the largest debris: It catches noticeable pieces of wax and wood.

- Preserve the "whole" product: It intentionally allows fine particles, most notably pollen grains, to remain suspended in the honey.

This is a statement of authenticity. It tells a story about a product that is as close to its natural state as possible.

The Pursuit of Perfection: Fine Straining

Conversely, the mainstream retail market demands a crystal-clear, polished product. This is achieved through fine straining, often using a multi-stage system.

- Coarse First Stage: A primary strainer removes the large particles.

- Fine Second Stage: A finer mesh (e.g., 200 microns) removes almost all remaining suspended solids.

This double-filtration process results in a brilliantly clear honey that gleams on the shelf. For a commercial operation, this level of polish is not just an aesthetic choice—it's a requirement to compete in a crowded market.

Scaling Filtration for Commercial Operations

What works for a hobbyist with a few hives is not viable for a commercial apiary. The process must be efficient, repeatable, and durable.

While a small-scale beekeeper might use a simple nylon strainer over a five-gallon bucket, a commercial operation requires robust, high-throughput systems. This means investing in equipment designed for scale:

- Material: Food-grade stainless steel is the standard for its durability, ease of cleaning, and non-reactive properties.

- Design: Multi-level strainers that fit securely over large bottling tanks or sumps.

- Efficiency: Systems that can handle a continuous flow of warm honey without clogging easily.

This is where equipment selection becomes a critical business decision. The right straining system prevents bottlenecks in your workflow, ensures consistent product quality across large batches, and withstands the rigors of daily use.

Your Strainer Is Your Strategy

Ultimately, the type of strainer you use is a direct reflection of your business strategy. It determines your product's final presentation, target market, and brand promise.

| Business Goal | Filtration Strategy | Recommended Equipment |

|---|---|---|

| Pristine Retail Product | Double Straining (Coarse + Fine) | Multi-level stainless steel strainer system |

| "Raw & Unfiltered" Artisan Honey | Single Coarse Straining | Wide-mouth, coarse-mesh stainless strainer |

| Bulk Honey for Food Service | Buyer-Specific (Often Fine) | High-throughput, fine-mesh filtration system |

At HONESTBEE, we understand that for commercial apiaries and distributors, equipment is the backbone of your operation. We provide the durable, commercial-grade honey strainers and processing equipment designed to ensure your quality control is flawless and your workflow is efficient.

To equip your operation with filtration systems that match your market ambitions, Contact Our Experts.

Visual Guide

Related Products

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

Related Articles

- The Precision Imperative: Why a 30-Second Calibration Prevents a Costly Harvest Failure

- How Queen Excluders Optimize Hive Productivity and Honey Quality

- Mastering the Craft: A Professional's Guide to Calibrating Your Honey Refractometer

- The Unseen Guardian: Strainer Mesh Size as a First Principle in Honey Processing

- The Last Gate: Why a Simple Strainer Defines Honey Quality at Any Scale