Proper honey mixer operation isn't just about efficiency—it's about protecting product quality and your investment. Commercial beekeepers lose thousands annually due to avoidable contamination incidents and mechanical failures. This guide details field-tested protocols for safe, compliant honey processing.

Operational Safety Protocols

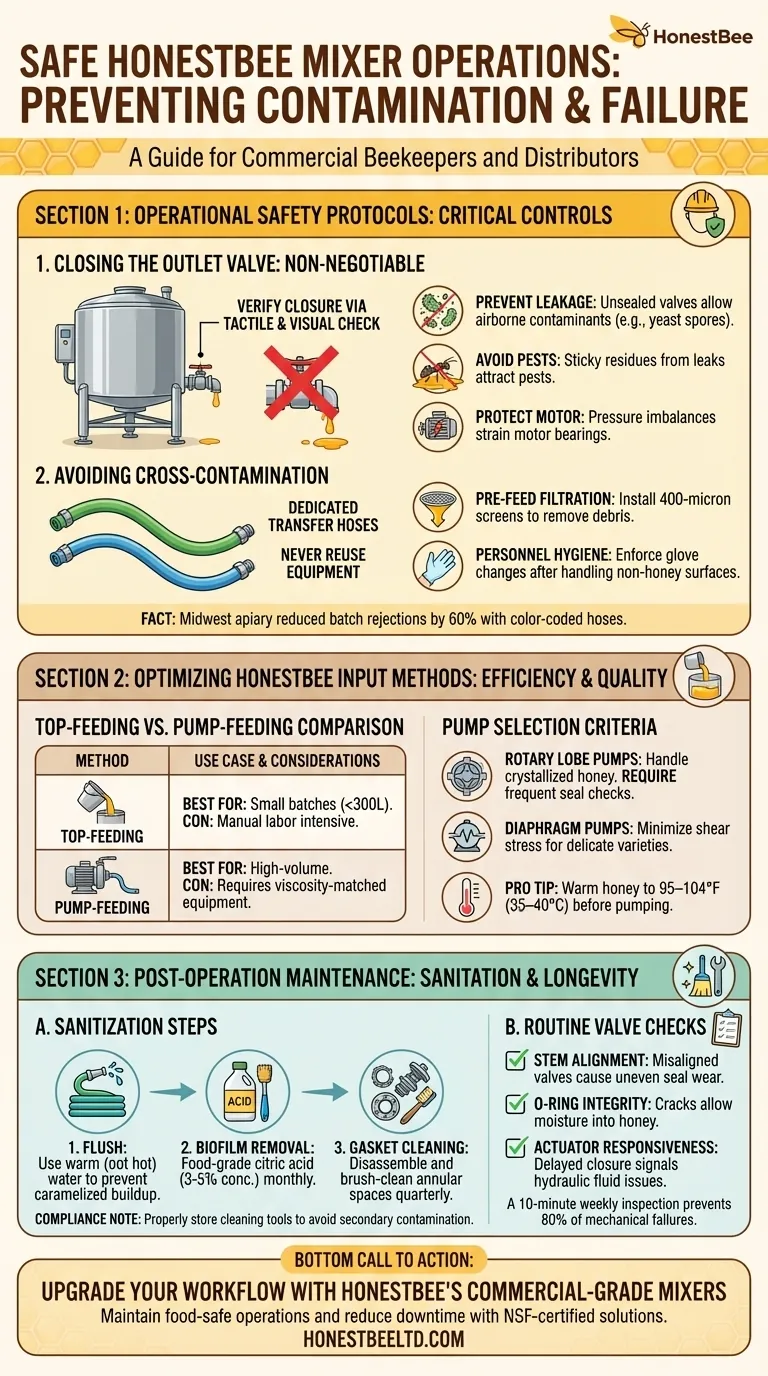

Why Closing the Outlet Valve is Non-Negotiable

Leaving the outlet valve open during filling is the leading cause of honey leakage and bacterial ingress. Research shows that:

- Unsealed valves allow airborne contaminants (e.g., yeast spores) to enter the mixer

- Sticky residues from leaks attract pests that compromise sanitation

- Pressure imbalances from open valves strain motor bearings

Best Practice: Always verify valve closure via tactile check (hand-tight) and visual inspection before feeding honey.

Avoiding Cross-Contamination During Honey Transfer

Honey’s low water activity doesn’t eliminate microbial risks. Critical control points include:

- Dedicated transfer hoses – Never reuse equipment between raw/unfiltered and processed batches

- Pre-feed filtration – Install 400-micron screens to remove wax debris that harbors bacteria

- Personnel hygiene – Enforce glove changes after handling non-honey surfaces

Real-world impact: A Midwest apiary reduced batch rejections by 60% after implementing color-coded hoses for different honey grades.

Optimizing Honey Input Methods

Top-Feeding vs. Pump-Feeding: Pros, Cons, and Use Cases

| Method | Best For | Limitations |

|---|---|---|

| Top-Feeding | Small batches (<300L) | Manual labor intensive |

| Pump-Feeding | High-volume operations | Requires viscosity-matched equipment |

Pump selection criteria:

- Rotary lobe pumps handle crystallized honey but require frequent seal checks

- Diaphragm pumps minimize shear stress for delicate floral varieties

Pro tip: Warm honey to 95–104°F (35–40°C) before pumping to reduce viscosity-related strain.

Post-Operation Maintenance

Sanitization Steps to Meet Food Safety Standards

Post-batch cleaning should address three contamination vectors:

- Residual honey – Flush with warm (not hot) water to prevent caramelized buildup

- Biofilms – Use food-grade citric acid solutions (3–5% concentration) monthly

- Gasket surfaces – Disassemble and brush-clean annular spaces quarterly

Compliance note: USDA audits frequently cite improperly stored cleaning tools as secondary contamination sources.

Routine Checks to Prevent Valve Malfunctions

A 10-minute weekly inspection prevents 80% of mechanical failures:

✔ Stem alignment – Misaligned valves cause uneven seal wear

✔ O-ring integrity – Cracks allow moisture absorption into honey

✔ Actuator responsiveness – Delayed closure signals hydraulic fluid issues

Ready to upgrade your honey processing workflow? HONESTBEE’s commercial-grade mixers and sanitation systems help distributors and large apiaries maintain food-safe operations while reducing downtime. Explore our NSF-certified solutions today.

Visual Guide

Related Products

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- 32 Frame Commercial Electric Honey Extractor for Beekeeping and Honey Production

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

Related Articles

- How to Choose and Optimize Queen Excluders for Healthier Hives

- How Dry Pollen Feeding Reduces Hive Robbing: Science-Backed Strategies for Beekeepers

- Mastering the Craft: A Professional's Guide to Calibrating Your Honey Refractometer

- The Last Gate: Why a Simple Strainer Defines Honey Quality at Any Scale

- How Honey Vacuum Thickeners Cut Costs Without Sacrificing Quality for Small Honey Producers