For any commercial beekeeping operation, honey is more than a sweet treat; it's a product with strict quality standards. The single most important factor in determining the shelf-life and grade of your honey is its moisture content. Honey with moisture levels above 18.6% is susceptible to fermentation, which can lead to spoiled batches, damaged customer relationships, and significant financial loss.

Your primary tool in this crucial quality control process is the honey refractometer. However, an uncalibrated refractometer is not just unreliable—it's a liability. Taking a few minutes to properly calibrate your instrument ensures every reading is accurate, protecting your product, your reputation, and your bottom line. This guide will walk you through the professional standard for calibration.

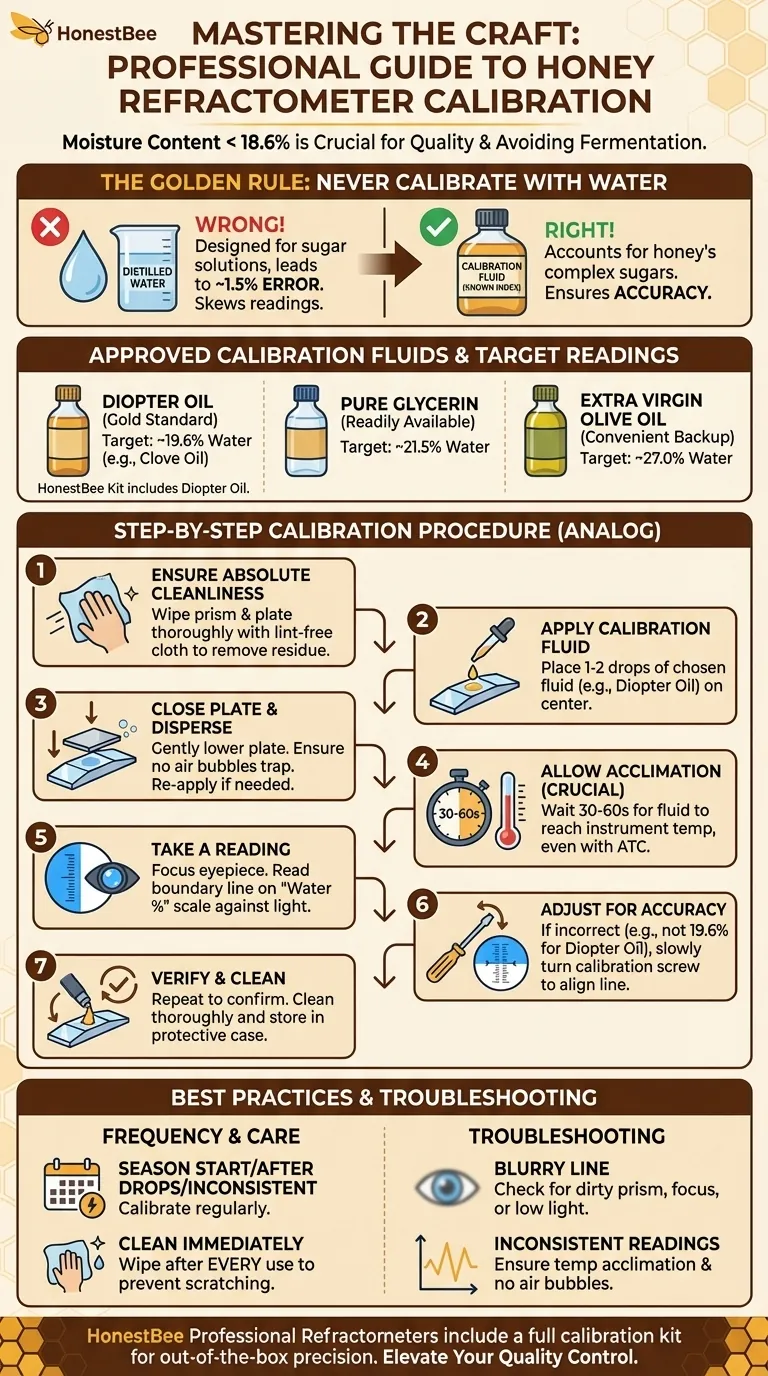

The Golden Rule: Never Calibrate a Honey Refractometer with Water

This is the most critical and most frequently made mistake. While standard Brix refractometers (used for simple sugar solutions) are correctly calibrated to zero with distilled water, honey refractometers are different.

They are specifically designed to account for the complex blend of sugars in honey, primarily fructose. Using water to set the "zero" point will skew all subsequent readings, typically causing them to read about 1.5% lower than the actual moisture content. This could lead you to bottle honey at 19.5% while believing it's a safe 18%.

To achieve true accuracy, you must use a calibration fluid with a known, stable refractive index. The industry-standard options are:

- Diopter Oil (Clove Oil or Alpha-Bromonaphthalene): This is the gold standard and the method preferred by professionals. It is exceptionally stable and provides a precise reading. The specific moisture value will be printed on the oil's bottle, but it is typically around 19.6% water (78.8 Brix).

- Pure Glycerin (Glycerol): An excellent and readily available alternative. On a honey refractometer, pure glycerin should give a consistent reading of approximately 21.5% water.

- High-Quality Extra Virgin Olive Oil: A surprisingly effective and convenient backup. A good quality, pure olive oil will consistently read at or very near 27.0% water (71.5 Brix). It's wise to test a new bottle against a known calibrated instrument to confirm its specific value for your future use.

Precision You Can Trust: The HONESTBEE Honey Refractometer

In commercial beekeeping, your tools can't be a weak link. That's why HONESTBEE designed its Honey Refractometer specifically for the rigors of professional use.

- Built for Durability: A robust, all-metal body designed to withstand daily use in the honey house.

- Crystal-Clear Optics: High-contrast, easy-to-read scale for fast and unambiguous readings.

- Automatic Temperature Compensation (ATC): Delivers accurate readings between 10°C and 30°C (50°F and 86°F) without the need for temperature correction charts—a vital feature for efficiency.

- Complete Professional Kit: Every HONESTBEE refractometer ships with a full calibration kit, including a vile of diopter oil, a calibration screwdriver, pipettes, and a lint-free cleaning cloth.

Equip your operation with a tool built for business. Contact HONESTBEE for wholesale pricing on all your beekeeping equipment needs.

Step-by-Step Calibration for Analog (Eyepiece) Refractometers

What You'll Need:

- Your honey refractometer

- Your chosen calibration fluid (Diopter Oil recommended)

- A plastic pipette

- The small screwdriver included with your kit

- A soft, lint-free microfiber cloth

The Procedure:

Step 1: Ensure Absolute Cleanliness Lift the daylight plate (the hinged cover). Using your lint-free cloth, thoroughly wipe both the glass prism surface and the underside of the daylight plate. Any residue—dust, fingerprints, or old honey—will interfere with an accurate reading.

Step 2: Apply the Calibration Fluid Using the pipette, place 1-2 drops of your diopter oil (or other chosen fluid) onto the center of the clean, dry prism. A small amount is all that is needed to cover the surface.

Step 3: Close the Plate and Disperse the Fluid Gently lower the daylight plate onto the prism. The fluid will spread evenly. Apply light pressure to ensure there are no air bubbles trapped, as these will disrupt the reading. If you see bubbles, lift, wipe clean, and re-apply.

Step 4: Allow for Temperature Acclimation Wait for approximately 30-60 seconds. This allows the fluid to reach the same temperature as the refractometer's prism. Even with ATC, this step is crucial for the internal bimetallic strip to adjust and provide a truly compensated reading.

Step 5: Take a Reading Hold the refractometer up to a source of natural light and look through the eyepiece. You will see a circular field with a scale. The upper part will be blue, and the lower part will be white. Turn the eyepiece to bring the scale and the dividing line into sharp focus.

Step 6: Adjust for Accuracy Read the value where the boundary line between the blue and white fields crosses the "Water %" scale.

- If using Diopter Oil, the line should be at the value specified on the bottle (e.g., 19.6%).

- If using Extra Virgin Olive Oil, the line should be at 27.0%.

If the reading is incorrect, locate the calibration screw. Use the provided screwdriver to slowly turn the screw while looking through the eyepiece until the boundary line rests exactly on the correct calibration mark.

Step 7: Verify and Clean Lift the plate, wipe the prism and plate completely clean, and repeat the entire process one more time to confirm your calibration is accurate. Once verified, clean the instrument thoroughly and store it in its protective case. It is now ready for professional use.

The HONESTBEE Advantage: Built for the Field, Priced for Your Business

At HONESTBEE, we are more than just a supplier; we are your partner in productivity. We understand that commercial beekeepers and distributors need equipment that is not only precise but also cost-effective and built to last.

Our entire product line, from hive tools and smokers to extractors and refractometers, is engineered for performance and offered at competitive wholesale pricing. We help you standardize your equipment, streamline your operations, and maximize the profitability of your harvest.

Looking to outfit your entire operation or stock your retail shelves? Contact our wholesale team today to receive our full catalog and discover the HONESTBEE difference.

Best Practices & Troubleshooting

- Calibration Frequency: Calibrate your refractometer at the beginning of each honey harvesting season, any time it has been dropped or handled roughly, or if you begin to get readings that seem inconsistent or suspect.

- Cleanliness is Paramount: Always clean your instrument with a damp cloth and dry it with a soft, lint-free cloth immediately after every use. Dried honey is abrasive and can permanently scratch the prism surface.

- Blurry Boundary Line: This is almost always caused by a dirty prism/plate, an out-of-focus eyepiece, or insufficient light.

- Inconsistent Readings: This can be caused by temperature fluctuations (not allowing the sample to acclimate) or microscopic air bubbles. Re-apply the sample carefully to resolve.

By integrating this simple calibration routine into your workflow, you ensure that every jar of honey you produce meets the highest standards of quality—a cornerstone of any successful beekeeping business.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

Related Articles

- From Profit to Spoilage: The One Number Every Commercial Beekeeper Must Know

- How to Perfect Honey Moisture Levels: A Beekeeper’s Guide to Refractometer Mastery

- Mastering Honey Refractometer Basics: A Guide to Precision and Profitability

- How Honey Refractometers Protect Profits: A Science-Backed Guide to Harvest Timing and Quality Control

- How Beekeepers Prevent Honey Spoilage Through Precision Moisture Control