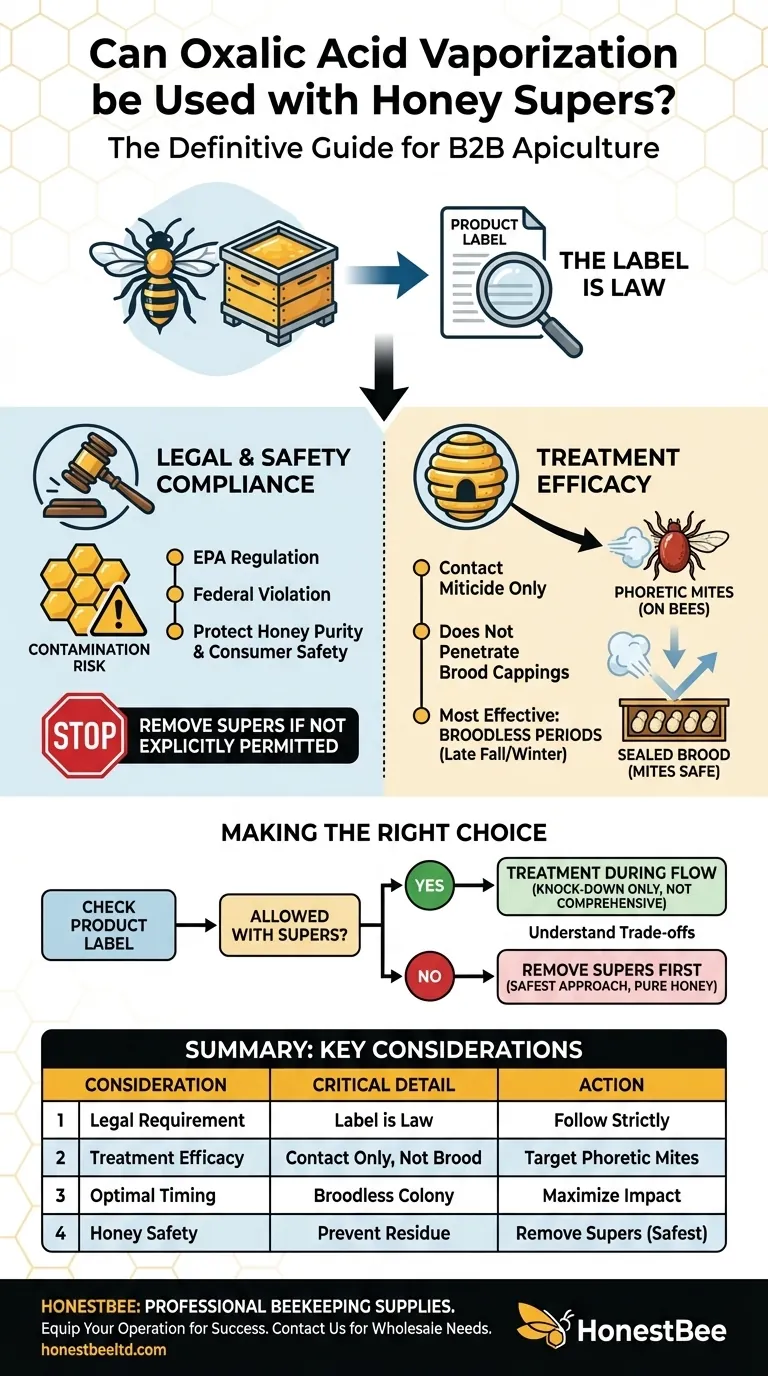

To be clear, the answer depends entirely on the specific oxalic acid product you are using and its legally binding label. If the product label explicitly permits application with honey supers on the hive, then it is allowed. Otherwise, you must remove the honey supers before treatment to ensure the safety and compliance of your honey harvest.

The core issue is not just about bee health, but about legal compliance and food safety. The product label is the definitive guide, and effective mite control with oxalic acid is fundamentally tied to the presence or absence of sealed brood in the hive.

The Core Principle: Why the Product Label is Law

When using any treatment in a beehive, the product label is not a suggestion—it is a legal requirement. This is especially true for treatments applied when honey intended for human consumption is present.

Legal and Safety Compliance

The label on your specific oxalic acid product (such as API-Bioxal) is a legal document regulated by agencies like the EPA. Using the product in a manner inconsistent with its labeling is a violation of federal law.

These regulations exist to prevent contamination of the food supply. Following the label protects both you as the beekeeper and the consumer of your honey.

Risk of Contamination

If a product is not approved for use with honey supers, it's because there is a risk of the chemical leaving residue in the honey.

Removing the supers before treatment is the most reliable way to prevent any potential for contamination and ensure your honey is pure and safe.

The Critical Factor: Treatment Efficacy

Beyond the legal requirements, you must consider whether the treatment will even be effective. The success of oxalic acid vaporization is dictated by the colony's brood cycle.

Understanding Phoretic Mites

Oxalic acid vaporization is a contact miticide. It only kills Varroa mites that are physically on the bodies of adult bees, known as phoretic mites.

The Problem with Brood

The treatment does not penetrate the wax cappings of brood cells. During a honey flow—the very time honey supers are on—a healthy hive has a large amount of sealed brood.

The majority of a hive's Varroa mite population (often up to 80%) is reproducing under these cappings, completely safe from the oxalic acid vapor.

The Broodless Advantage

For this reason, oxalic acid is most effective when the colony is broodless or has very little brood. This typically occurs in late fall, early winter, or during a package installation.

Treating a broodless colony allows the vapor to contact nearly every mite in the hive, resulting in a highly effective "clean-up" treatment.

Understanding the Trade-offs

Treating with supers on, even if the label permits it, involves significant compromises that every beekeeper must weigh.

Treating During a Honey Flow

If your label allows treatment with supers on, you must recognize its limitation. This is only a "knock-down" for the phoretic mite population.

It can help manage mite loads temporarily but will not resolve a serious infestation because it leaves the mites in the brood untouched.

Removing Supers: The Safest Approach

The industry-standard best practice is to remove all honey supers intended for harvest before any mite treatment.

This eliminates any confusion or risk regarding legality and food safety. Once the honey is harvested, you can then focus on the most effective mite treatment strategy for that time of year.

Making the Right Choice for Your Hives

Your decision must balance regulatory compliance, honey safety, and the actual effectiveness of the mite treatment.

- If your primary focus is legal compliance and honey safety: Always remove honey supers before treatment unless your specific product label explicitly and unequivocally states it is safe to leave them on.

- If your primary focus is maximum mite control: Use oxalic acid vaporization when the colony is broodless to achieve the highest possible efficacy against your hive's entire Varroa mite population.

- If you must treat during a honey flow: First, confirm your product label allows for it. Second, understand you are only targeting a fraction of the mites and will need a more comprehensive treatment plan after you pull your honey.

Ultimately, aligning your mite treatment strategy with the bees' natural cycle and adhering strictly to product labels will ensure both a healthy colony and a safe honey harvest.

Summary Table:

| Key Consideration | Critical Detail |

|---|---|

| Legal Requirement | The product label is law. Using it inconsistently is a federal violation. |

| Treatment Efficacy | Oxalic acid is a contact miticide; it does not penetrate sealed brood cells. |

| Optimal Timing | Most effective when the colony is broodless (e.g., late fall, early winter). |

| Honey Safety | Removing supers before treatment is the safest way to prevent contamination. |

Protect Your Hives and Your Harvest with the Right Equipment

Managing Varroa mites effectively requires not just knowledge but also reliable, high-quality equipment. Whether you're a commercial apiary or a beekeeping equipment distributor, having the right tools is essential for safe and compliant treatments.

HONESTBEE supplies professional-grade beekeeping supplies and equipment designed for the demands of modern beekeeping. We help you maintain hive health and ensure the purity of your honey harvest.

Ready to equip your operation for success? Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment can support your mite management strategy.

Visual Guide

Related Products

- Heavy Duty 12V Oxalic Acid Evaporator Vaporizer for Bee Varroa Mite Treatment Beekeeping Fumigator Atomizer

- Oxalic Acid Vaporizer 12V for Bee Varroa Mite Treatment

- Durable 12V Oxalic Acid Vaporizer for Varroa Mite Treatment Beehive Beekeeping Tool

- 12V Bee Mite Removal Evaporator Oxalic Acid Vaporizer for Bee Fumigation Treatment 180W Atomization

- Wooden Bee Brush with Double-Row Horsehair Bristles

People Also Ask

- What safety precautions should be taken when using oxalic acid for vaporization? Protect Yourself and Your Bees

- Why are stainless steel screen bottom boards required when performing Varroa mite treatments with Oxalic Acid? IPM Guide

- Why is winter a good time to treat hives with Oxalic Acid? Maximize Varroa Mite Control with a Brood Break

- What should be done after applying the vapor? A Step-by-Step Guide to Sealing Your Hive

- What are the registered application methods for oxalic acid in honey bee colonies? 3 Proven Ways to Control Varroa Mites