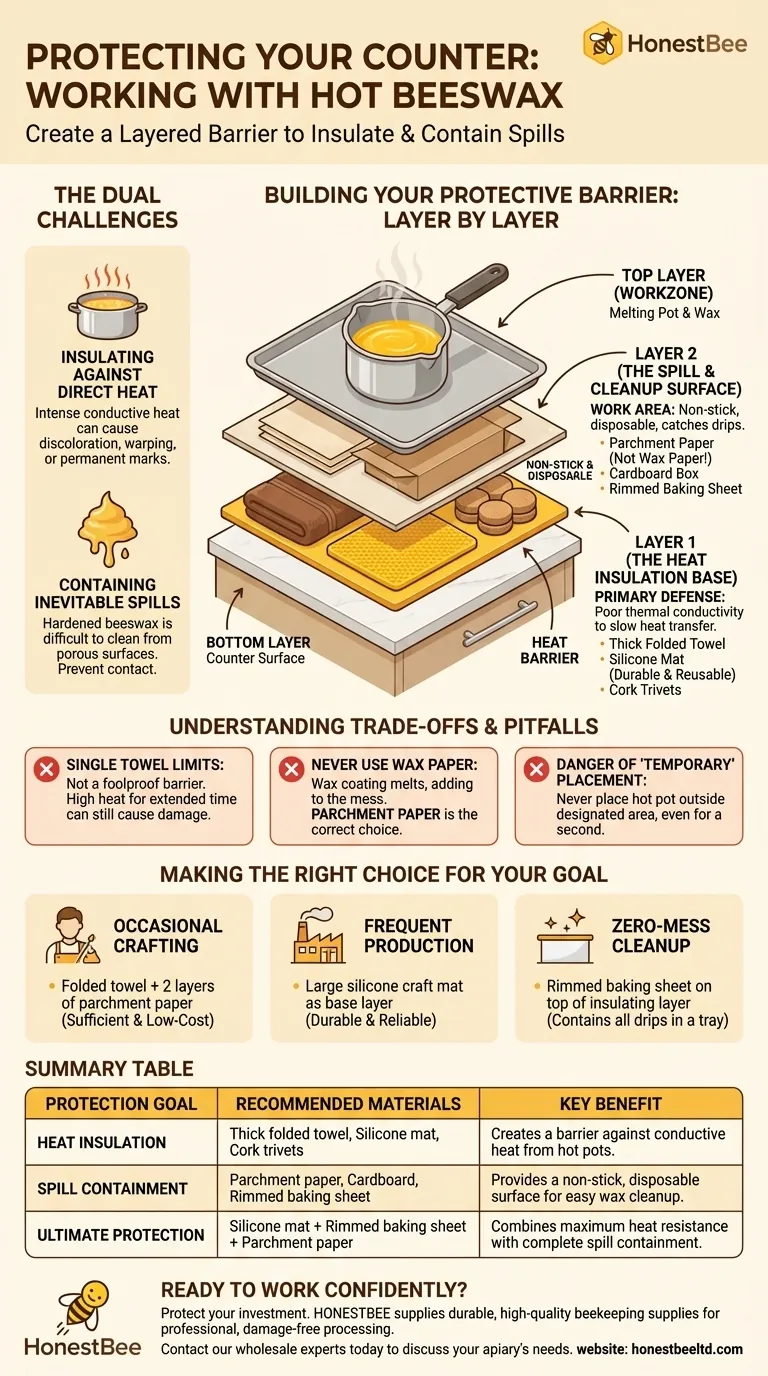

To protect your counter from heat when working with beeswax, you must create a layered barrier that both insulates the surface and contains spills. The most effective approach involves placing a heat-resistant base, such as a thick folded towel or a silicone mat, directly on the counter. You then cover this entire workspace with a non-stick, disposable material like multiple layers of parchment paper to catch wax drips.

Your primary goal is to create a complete, self-contained workstation. True protection comes not from a single material, but from a layered system that insulates your counter from the direct heat of your melting pot while providing a surface that makes wax cleanup effortless.

The Foundational Principles of Surface Protection

Working with hot wax presents two distinct challenges to your surfaces: the intense, focused heat from your melting equipment and the inevitable spills and drips of the wax itself. A proper setup must address both.

Insulating Against Direct Heat

The most immediate danger to a countertop, especially laminate or solid surface, is the conductive heat from a hot melting pot. Placing it directly on the counter, even for a moment, can cause discoloration, warping, or permanent marks.

Your first layer of defense must be a material with poor thermal conductivity. This insulation creates a buffer that slows the transfer of heat from the pot to the counter.

Containing Inevitable Spills

Beeswax, while wonderful to work with, can be difficult to clean from porous or textured surfaces once it cools and hardens. A key part of protecting your counter is preventing the wax from ever touching it in the first place.

This requires a non-stick, disposable top layer that can catch any drips or accidental spills, which can then be easily folded up and discarded after your session.

Building Your Protective Barrier: Layer by Layer

A robust setup combines materials to solve the dual problems of heat and mess. Think of it as building from the counter up.

Layer 1: The Heat Insulation Base

This is your primary defense against heat damage. You have several effective options:

- Thick, Folded Towel: A simple bath or kitchen towel folded over several times is an accessible and effective insulator. The trapped air between the fibers is what slows heat transfer.

- Silicone Mat: A silicone baking or craft mat is an excellent investment. These are specifically designed to withstand high temperatures and provide a stable, non-slip base.

- Cork Trivets: Cork is a natural and highly effective insulator. Placing several large cork trivets under your primary heating area works very well.

Layer 2: The Spill & Cleanup Surface

This layer sits on top of your heat insulation base and serves as your main work area.

- Parchment Paper: As noted in the references, parchment paper is ideal. It is coated with silicone, making it heat-resistant and non-stick. Use at least two to three layers to ensure nothing seeps through.

- Cardboard: A large, flattened cardboard box provides a fantastic, free work surface. It absorbs small spills and is rigid enough to work on.

- Rimmed Baking Sheet: For the ultimate in containment, place a large, rimmed baking sheet on top of your towel or silicone mat. This creates a physical barrier that stops wax from dripping onto the floor. You can then line the sheet with parchment paper for easy cleanup.

Understanding the Trade-offs and Pitfalls

While simple materials work, it's crucial to understand their limitations to avoid costly mistakes.

The Limits of a Single Towel

A towel provides good insulation, but it is not a foolproof heat barrier. An extremely hot pot left for an extended period can still transfer enough heat to cause damage. It also offers no containment for major spills.

Parchment vs. Wax Paper

Never substitute wax paper for parchment paper. The wax coating on wax paper will melt when it comes into contact with a hot pot or fresh wax drips, adding to the mess rather than preventing it. Parchment paper is heat-resistant and the correct choice for this work.

The Danger of a "Temporary" Placement

The most common way countertops are damaged is by placing a hot pot down "just for a second" outside the protected area. Be disciplined and treat any surface outside your designated workstation as off-limits to hot equipment.

Making the Right Choice for Your Goal

Your ideal setup depends on how frequently you work with beeswax and your tolerance for cleanup.

- If your primary focus is occasional crafting: A thick, folded bath towel covered with two layers of parchment paper is a sufficient and low-cost solution.

- If your primary focus is frequent production: Invest in a large silicone craft mat as your base layer for durable, reliable, and reusable heat protection.

- If your primary focus is zero-mess cleanup: Place a rimmed baking sheet on top of your heat-insulating layer to contain all drips and spills within a defined tray.

By building a thoughtful, layered workspace, you can focus on your craft with confidence, knowing your surfaces are completely protected.

Summary Table:

| Protection Goal | Recommended Materials | Key Benefit |

|---|---|---|

| Heat Insulation | Thick folded towel, Silicone mat, Cork trivets | Creates a barrier against conductive heat from hot pots. |

| Spill Containment | Parchment paper, Cardboard, Rimmed baking sheet | Provides a non-stick, disposable surface for easy wax cleanup. |

| Ultimate Protection | Silicone mat + Rimmed baking sheet + Parchment paper | Combines maximum heat resistance with complete spill containment. |

Ready to work with beeswax confidently and efficiently?

As a commercial beekeeper or equipment distributor, protecting your investment in your workspace is crucial. HONESTBEE supplies the durable, high-quality beekeeping supplies and equipment you need to build a professional, damage-free processing station. From heat-resistant silicone mats to other essential tools, we help you maximize productivity and minimize cleanup time.

Contact our wholesale experts today to discuss your apiary's supply needs and discover how our products can protect your surfaces and streamline your operation.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Stainless Steel Honey Press Wax Press with Tank

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What are the cost-saving benefits of using fully automatic wax foundation machines? Maximize ROI for Commercial Apiaries

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What are the key features of the beeswax foundation machine's mold surface? Non-Stick, Durable & Precise

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency