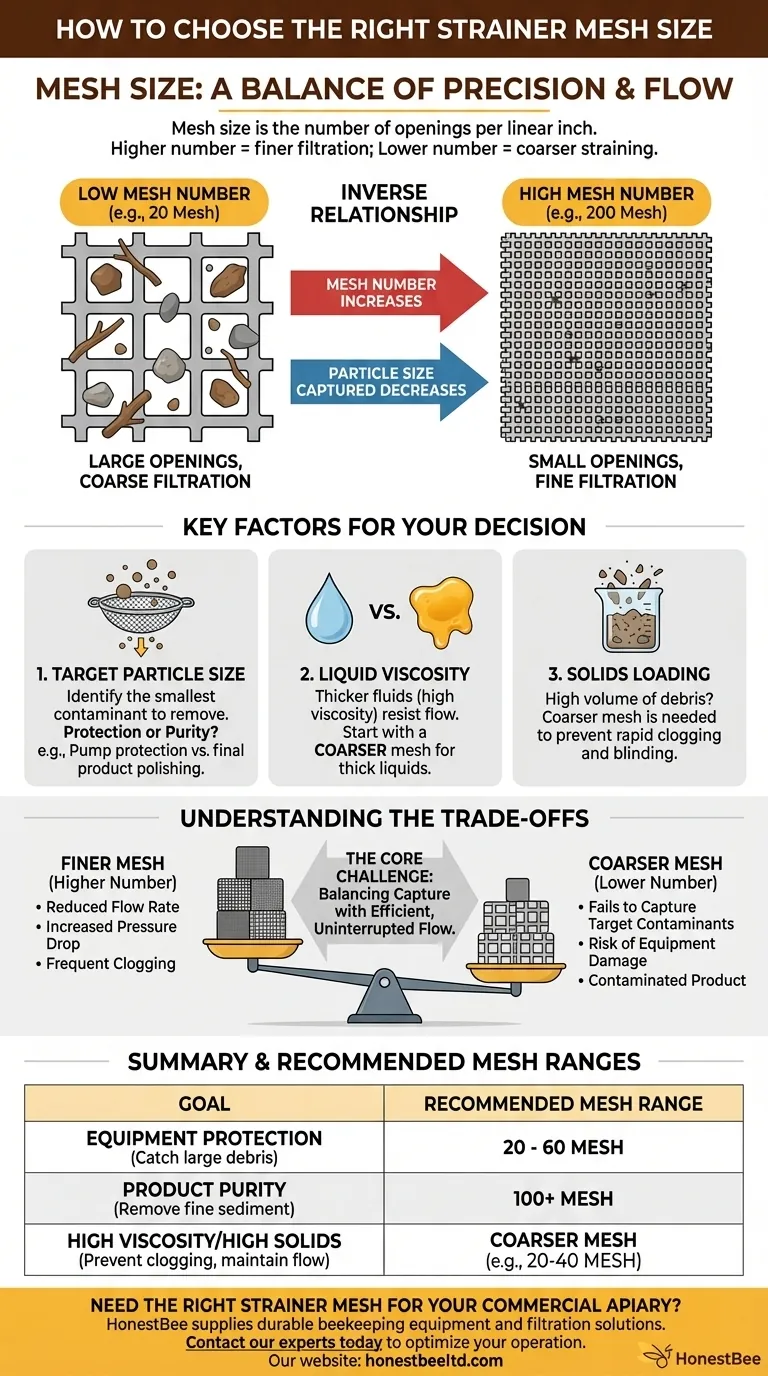

To determine the right mesh size for your strainer, you must first identify the size of the smallest particle you need to remove from your liquid. Mesh size is a simple measurement of how many openings exist in one linear inch of a screen; a higher number means smaller openings for finer filtration, while a lower number means larger openings for coarser straining. The choice is a direct trade-off between filtration precision and the flow rate of your liquid.

The core challenge in selecting a strainer mesh is balancing two competing goals: capturing the necessary contaminants (which requires a finer, higher-number mesh) and maintaining an efficient, uninterrupted flow (which is easier with a coarser, lower-number mesh).

Deconstructing Mesh Size

Before you can choose the right size, you need a clear understanding of the terminology. The terms "mesh size" and "micron rating" are often used together, and their relationship is key.

What is Mesh Size?

Mesh size is a count of the number of openings per linear inch of a screen. It's an easy way to understand the relative fineness of a filter.

For example, a 10 mesh screen has 10 openings per inch. Think of a common window screen.

A 100 mesh screen has 100 openings per inch. The openings are significantly smaller and the filtration is much finer, like a piece of silk.

The Inverse Relationship

It's critical to remember the relationship is inverse. As the mesh number goes up, the size of the openings—and the particles that can pass through—goes down.

- Low Mesh Number (e.g., 20): Large openings, coarse filtration.

- High Mesh Number (e.g., 200): Small openings, fine filtration.

Key Factors Driving Your Decision

Selecting the optimal mesh size depends entirely on the specifics of your application. You must evaluate three primary factors.

1. The Target Particle Size

This is the most important factor. You must know what you are trying to capture. Are you protecting a pump from large debris like twigs and gravel, or are you purifying a chemical by removing microscopic sediment?

If you don't know the exact size, define the purpose of the filtration. Is it for general protection or for ensuring final product purity?

2. The Liquid's Viscosity

Viscosity is a measure of a fluid's resistance to flow. Water has a very low viscosity, while honey has a high viscosity.

A thick, viscous fluid will struggle to pass through a fine mesh screen. Using too fine a mesh can dramatically slow your flow rate or stop it altogether. For high-viscosity liquids, you must start with a coarser mesh.

3. The Amount of Solids (Solids Loading)

Consider how much debris you expect to capture. A liquid with a high concentration of suspended solids will clog a fine screen very quickly. This phenomenon is often called blinding.

If your process involves a high solids load, a coarser mesh is often necessary to extend the time between cleanings and prevent a sudden drop in pressure and flow.

Understanding the Trade-offs

Every choice is a compromise. Being aware of the potential downsides of going too fine or too coarse is essential for making an effective decision.

The Cost of a Finer Mesh

Using a mesh that is too fine (a number that's too high) for your application creates several problems.

- Reduced Flow Rate: The smaller openings create more resistance, slowing down your entire process.

- Increased Pressure Drop: The strainer will cause a greater pressure loss in the system, which can affect downstream equipment.

- Frequent Clogging: The screen will capture particles more rapidly, requiring more frequent shutdown and cleaning.

The Risk of a Coarser Mesh

Using a mesh that is too coarse (a number that's too low) has one primary, but significant, risk.

The strainer will fail to capture the target contaminants. This can lead to damaged downstream equipment (like pumps, valves, and nozzles), a contaminated final product, or a failed process.

Making the Right Choice for Your Application

Use your operational goal as the final guide. There is no single "best" mesh size—only the one that is most appropriate for your specific task.

- If your primary focus is protecting equipment: Start with a coarser mesh (e.g., 20 to 60 mesh) designed to catch only the larger debris that could cause mechanical damage.

- If your primary focus is product purity: You must determine the acceptable particle size in your final product and select a finer mesh (e.g., 100 mesh and higher) that reliably removes it.

- If you are working with a thick fluid or high debris: Prioritize flow by choosing a coarser mesh and consider multi-stage filtration if finer purification is also needed.

- If you are unsure: Begin with a coarser mesh than you think you need. It is always safer to allow some small, harmless particles through than it is to shut down your entire flow.

Ultimately, the right mesh is the one that removes what you need without impeding your process.

Summary Table:

| Factor | Goal | Recommended Mesh Range |

|---|---|---|

| Equipment Protection | Catch large debris (twigs, gravel) | 20 - 60 mesh |

| Product Purity | Remove fine sediment for purity | 100+ mesh |

| High Viscosity/High Solids | Prevent clogging, maintain flow | Coarser mesh (e.g., 20-40) |

Need the right strainer mesh for your commercial apiary? HONESTBEE supplies durable, high-performance beekeeping equipment and filtration solutions to commercial apiaries and distributors. We can help you select the ideal mesh to protect your pumps and ensure honey purity without sacrificing flow. Contact our experts today to discuss your specific needs and optimize your operation.

Visual Guide

Related Products

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- 10L Stainless Steel Electric Honey Press Machine

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

- Premium Ventilated Goatskin Beekeeping Gloves with Full 3-Layer Mesh Sleeve

People Also Ask

- How do you strain honey at home? A Step-by-Step Guide to Pure, Raw Honey

- What is the best cloth for straining honey? Achieve Perfect Clarity with the Right Filtration System

- What is the purpose of the raised frame on the honey press? Simplify Logistics and Improve Extraction Workflow

- What cloth for straining honey? The Best Materials for Clean, High-Quality Honey

- Why are honey filtration equipment and consumables critical? Boost Market Value with Professional Processing