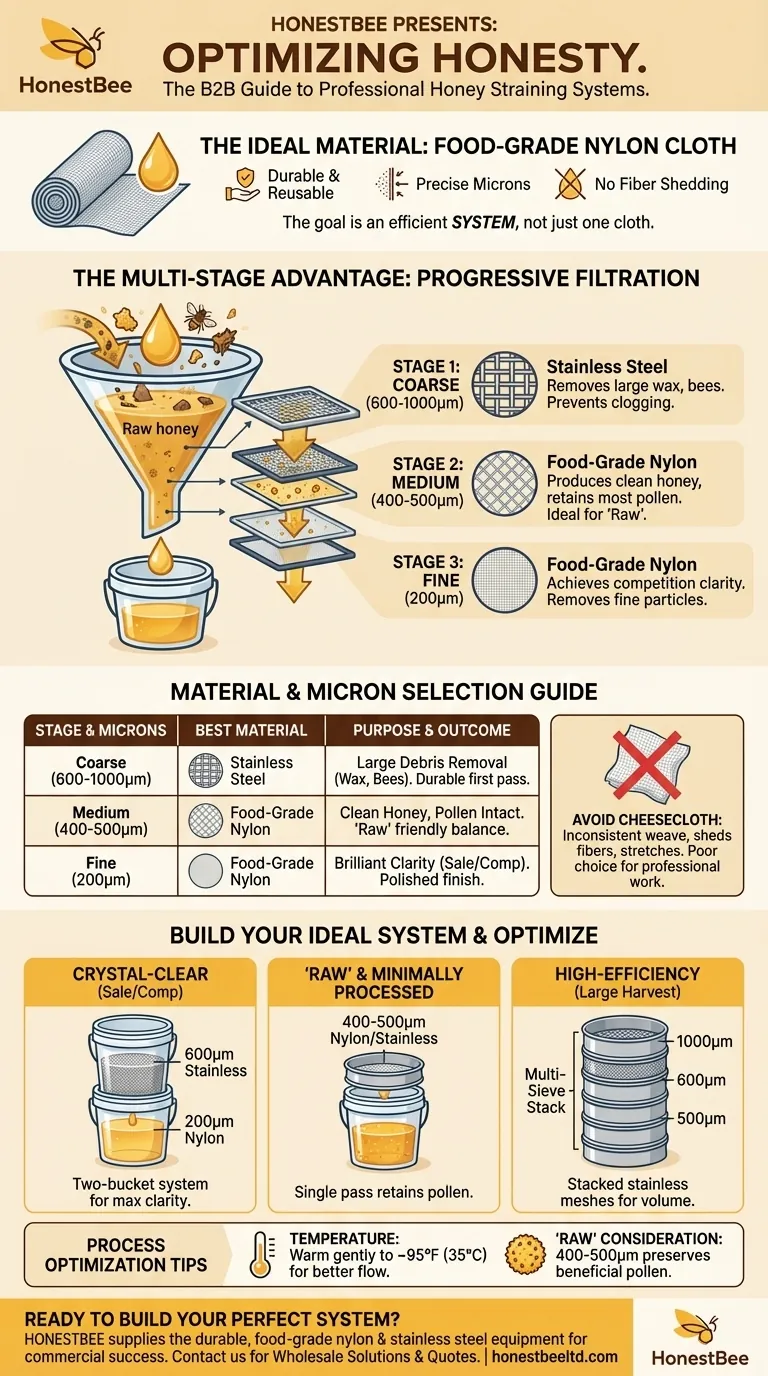

For straining honey, the ideal material is food-grade nylon cloth. Often sold under brand names like Nytrel, this fabric is superior because it is durable, reusable, does not shed fibers into the honey, and is available in precise mesh sizes (measured in microns). This allows you to control the exact level of filtration to achieve your desired clarity.

The goal of straining is not just to find one perfect cloth, but to create an efficient system. The most effective approach uses progressive, multi-stage filtration, moving from a coarse mesh to a finer one to remove debris without instantly clogging your equipment.

Why Straining Honey Is a Balancing Act

When you uncap frames and spin them in an extractor, the resulting honey contains debris. This includes bits of wax cappings, propolis, wood splinters, and occasionally bee parts.

Straining is the process of removing these particles, but it presents a core challenge: balancing purity with efficiency.

The Role of Mesh Size (Microns)

The key to understanding straining is the micron. One micron is one-thousandth of a millimeter. A smaller micron number means a finer mesh and more thorough filtration.

-

Coarse Straining (600-1000 microns): This is the first pass. A mesh at this level, typically made of stainless steel, catches large debris like chunks of wax and bees. It is essential for preventing your finer filters from clogging.

-

Medium Straining (400-500 microns): This is a very common size for a final strain. It produces a clean, appealing honey that still contains most of its pollen. For many hobbyists, this is the perfect balance.

-

Fine Straining (200 microns): This is the standard for producing exceptionally clear, brilliant honey suitable for competition or sale. A 200-micron nylon filter will remove nearly all visible wax flecks and other suspended particles.

Evaluating Your Material Options

While many fabrics can technically strain honey, only a few are well-suited for the task.

Nylon: The Professional Standard

Food-grade nylon cloth is the best choice for fine and medium filtering. It is strong, easy to clean with warm water, and can be reused for many seasons.

Most importantly, nylon filters are sold with precise micron ratings, giving you complete control over the final product.

Stainless Steel: The Durable First Pass

Stainless steel mesh is the workhorse of coarse straining. It is incredibly durable, easy to scrape clean of wax, and will last a lifetime.

While effective for the initial pass, stainless steel becomes less practical and more expensive for the very fine meshes required for final polishing.

Cheesecloth: The Common (But Flawed) Alternative

Many beginners start with cheesecloth, but it is a poor choice for serious work. Its weave is inconsistent, it can stretch and tear under the weight of honey, and it can shed fibers.

If you must use it, opt for multiple layers, but plan to upgrade to nylon as soon as possible.

Understanding the Trade-offs

An effective straining process is about more than just the material; it's about the method.

Single-Stage vs. Multi-Stage Straining

Pouring raw extracted honey directly through a fine 200-micron filter is a recipe for frustration. The wax and large debris will clog it almost immediately, stopping the flow.

The solution is multi-stage straining. By placing a coarse (600 micron) strainer over your bucket first, you remove the large particles. The honey then flows through to a finer (200-400 micron) filter below, which can do its job without clogging.

The Impact of Temperature

Honey viscosity is highly dependent on temperature. Cold, thick honey strains incredibly slowly.

Gently warming your honey to around 95°F (35°C)—roughly the natural temperature inside a hive—will make it far more fluid. This dramatically speeds up the straining process without degrading the honey's quality. Never heat honey excessively, as it can destroy beneficial enzymes and alter the flavor.

The "Raw Honey" Consideration

The definition of "raw honey" can be contentious, but it generally implies minimal processing. Aggressive filtering, especially below 100 microns, can remove a significant amount of pollen.

If you intend to market or consume your honey as "raw and unfiltered," using a 400- or 500-micron mesh is often the preferred choice. It removes unwanted debris while leaving the microscopic pollen grains intact.

How to Build Your Ideal Straining System

There is no single "best" setup; the right choice depends on your specific goal.

- If your primary focus is crystal-clear honey for sale or competition: Use a two-bucket system with a 600-micron coarse strainer on top, emptying into a second bucket fitted with a 200-micron nylon filter.

- If your primary focus is raw, minimally processed honey: Use a single 400- or 500-micron nylon or stainless steel strainer to remove major debris while retaining the maximum amount of pollen.

- If your primary focus is maximum efficiency for a large harvest: Invest in a multi-sieve strainer, which stacks several stainless steel meshes of decreasing size (e.g., 1000, 600, and 500 microns) in one unit.

By understanding the principles of filtration, you can move beyond simply buying a cloth and start designing a process that yields perfect honey every time.

Summary Table:

| Filtration Stage | Recommended Micron Size | Best Material | Purpose |

|---|---|---|---|

| Coarse Straining | 600-1000 microns | Stainless Steel | Remove large debris (wax, bees) |

| Medium Straining | 400-500 microns | Food-Grade Nylon | Produce clean honey with pollen intact |

| Fine Straining | 200 microns | Food-Grade Nylon | Achieve brilliant clarity for sale/competition |

Ready to Build Your Perfect Honey Straining System?

As a commercial beekeeper or distributor, your efficiency and product quality are paramount. HONESTBEE supplies the durable, food-grade nylon cloth and stainless steel equipment you need to implement a professional multi-stage filtration process. We provide wholesale-focused solutions to help you maximize your harvest yield and produce consistently clear, high-quality honey.

Contact HONESTBEE today to discuss your specific needs and get a quote on our reliable beekeeping supplies.

Visual Guide

Related Products

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Commercial 48-Frame Stainless Steel Honey Extractor

People Also Ask

- What cloth for straining honey? The Best Materials for Clean, High-Quality Honey

- What are the selection criteria for propolis centrifugation and filtration consumables? Ensure Purity and Bioactivity

- What is the method for processing honey from top bar hives? A Guide to Simple Crush & Strain

- How do I strain my honey? A Step-by-Step Guide to Clean, Pure Harvests

- What size mesh for straining honey? Master the Two-Stage System for Clean, Raw Honey