For straining honey, the most common and effective materials are food-grade nylon or a specialized type called Nytrel cloth. These fabrics are chosen for their durability, reusability, and precise mesh sizes that effectively remove debris without stripping the honey of its beneficial components.

The goal of straining is to remove physical impurities like wax bits and bee parts while preserving the valuable pollen. The best material for this task is a durable, food-safe nylon mesh, as its effectiveness depends entirely on selecting the correct weave coarseness for your needs.

Why Straining Honey is a Critical Step

Properly straining honey is a non-negotiable step in the harvesting process. It directly impacts the final product's quality, clarity, and shelf stability.

Removing Physical Debris

The primary goal is to filter out unwanted solid materials that accumulate during extraction. This includes bits of beeswax, propolis, and parts of bees.

Removing this debris results in a cleaner, more appealing product for consumption.

Preserving Honey's Natural Qualities

While filtering is essential, over-filtering can be detrimental. Using a mesh that is too fine can strip the honey of naturally occurring and beneficial pollen grains.

The ideal process balances purity with the preservation of these natural elements.

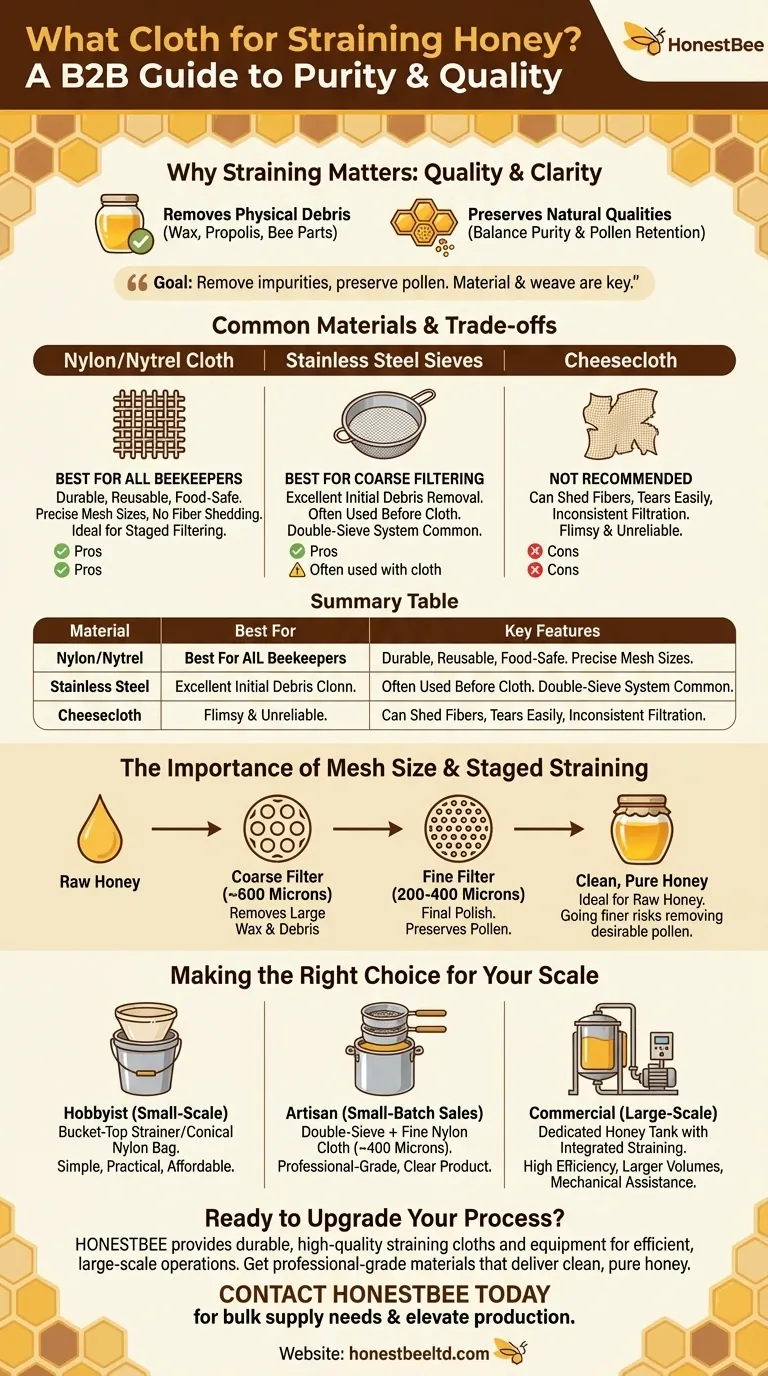

Common Materials and Their Properties

Your choice of material will depend on the scale of your operation and your desired outcome. While several options exist, one stands out as the professional standard.

Nylon or Nytrel Cloth

This is the industry standard for both hobbyists and commercial beekeepers. Nytrel is a specific type of nylon known for its durability.

These cloths are strong, easy to wash, reusable, and do not shed fibers into the honey. They are available in various mesh sizes (measured in microns) to allow for staged filtering, from coarse to fine.

Stainless Steel Sieves

Often used in conjunction with cloth, stainless steel sieves are excellent for the initial, coarse filtering step. Many beekeepers use a double-sieve system, with a wider mesh on top to catch large debris and a finer one below.

After passing through the metal sieves, the honey may then be strained through a finer nylon bag for a final polish.

Cheesecloth

While commonly available, cheesecloth is generally not recommended for serious honey processing.

It can be flimsy, tear easily under the weight of honey, and may shed lint fibers into your final product. Its inconsistent weave also makes achieving a reliable level of filtration difficult.

Understanding the Trade-offs

The effectiveness of your straining process is not just about the material, but how you use it. The scale of your operation dictates the best method.

Small-Scale vs. Large-Scale Methods

For a hobbyist, manually straining through a nylon bag or cloth fitted over a food-grade bucket is perfectly sufficient. This method is cost-effective and gives you complete control.

Large-scale commercial operations often use jacketed tanks that gently preheat the honey. This lowers its viscosity, allowing it to pass through strainers more quickly and efficiently with mechanical assistance.

The Importance of Mesh Size

Straining is often done in stages. A coarse filter (around 600 microns) removes the large wax pieces first, followed by a finer filter (200-400 microns) for a final polish.

Going much finer than 200 microns risks removing desirable pollen and is generally unnecessary for raw honey.

Making the Right Choice for Your Goal

Select your equipment based on your beekeeping goals and the volume of honey you are processing.

- If your primary focus is hobby-level harvesting: A simple 5-gallon bucket-top strainer made of nylon mesh or a conical nylon straining bag is the most practical and affordable solution.

- If your primary focus is small-batch artisan sales: Invest in a double-sieve stainless steel system for coarse filtering, followed by a fine nylon cloth (around 400 microns) for a clear, professional-grade final product.

- If your primary focus is scaling up your operation: Consider a dedicated honey tank with an integrated straining system to improve efficiency and handle larger volumes.

Choosing the right tool ensures your final product is clean, pure, and retains all the natural goodness of the hive.

Summary Table:

| Material | Best For | Key Features |

|---|---|---|

| Nylon/Nytrel Cloth | All Beekeepers | Durable, reusable, food-safe, precise mesh sizes |

| Stainless Steel Sieves | Coarse Filtering | Excellent for initial debris removal, often used with cloth |

| Cheesecloth | Not Recommended | Can shed fibers, tears easily, inconsistent filtration |

Ready to upgrade your honey harvesting process?

As a trusted supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-quality straining cloths and equipment you need for efficient, large-scale operations. Our wholesale-focused offerings ensure you get professional-grade materials that deliver clean, pure honey while preserving its natural qualities.

Contact HONESTBEE today to discuss your bulk supply needs and elevate your honey production.

Visual Guide

Related Products

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Plastic Honey Gate Spout with Wing Nut for Beekeeping Honey Bucket

People Also Ask

- What's the best way to strain honey? Master the Gentle Crush & Strain Method

- What size mesh for straining honey? Master the Two-Stage System for Clean, Raw Honey

- What is the method for processing honey from top bar hives? A Guide to Simple Crush & Strain

- What is the best cloth for straining honey? Achieve Perfect Clarity with the Right Filtration System

- Why are honey filtration equipment and consumables critical? Boost Market Value with Professional Processing