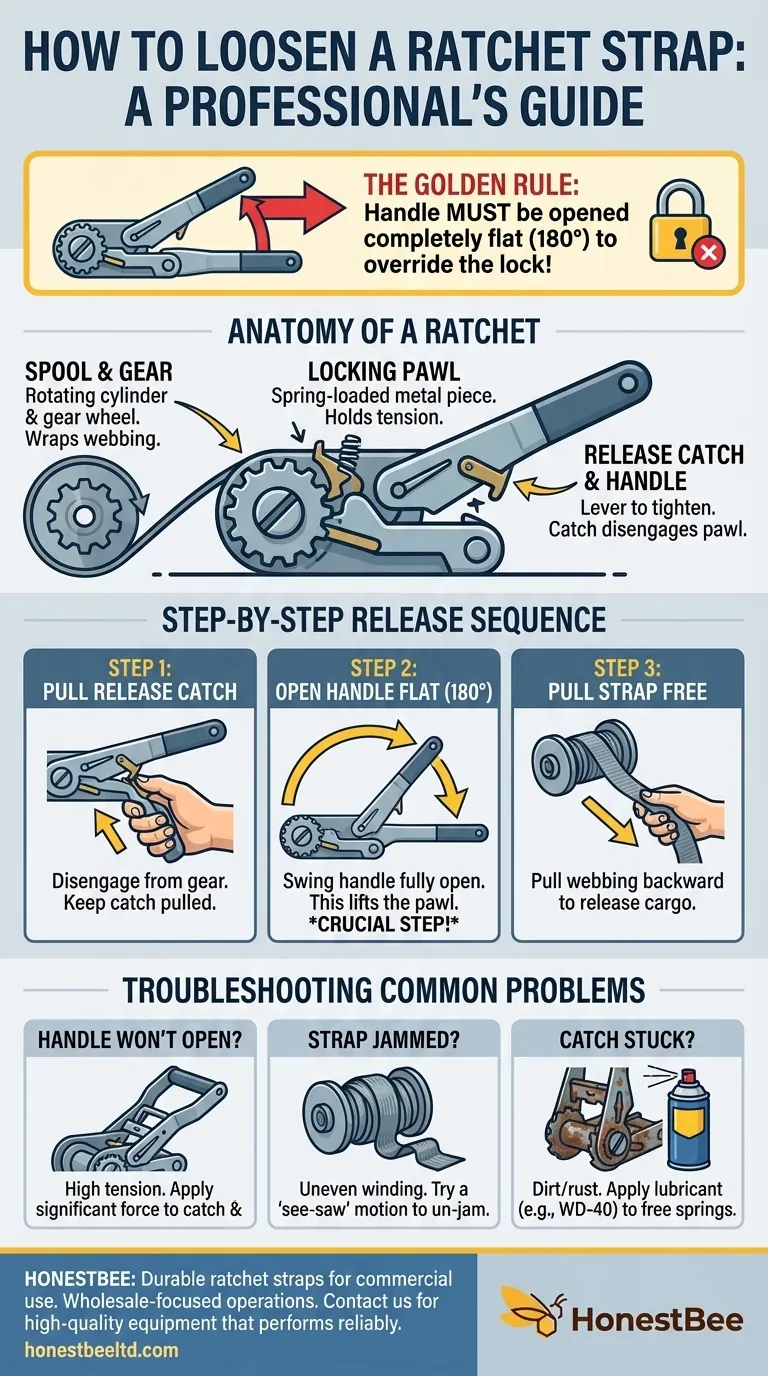

To loosen a ratchet strap, you must first disengage the locking mechanism by pulling the release catch and fully opening the ratchet handle until it lies completely flat. Once the handle is in this 180-degree open position, the tension on the main gear is released, allowing you to pull the strap webbing freely from the spool.

The most common point of failure is not opening the ratchet handle far enough. It must be moved past the tightening positions and laid completely flat to override the internal lock and release the strap.

Understanding the Ratchet's Core Components

To operate a ratchet strap effectively, it helps to understand its three key parts. This simple mechanical knowledge transforms the process from a frustrating struggle into a predictable action.

The Spool and Gear

The spool, or axle, is the rotating cylinder that the strap webbing wraps around. It is connected to a gear wheel with teeth.

The Locking Pawl

This is the heart of the mechanism. The locking pawl is a small, spring-loaded piece of metal that drops into the teeth of the gear as you tighten the strap. It prevents the spool from spinning backward, securely holding all the tension.

The Release Catch and Handle

The handle is your lever for tightening. Within the handle, there is a smaller, spring-loaded release catch or lever. Pulling this catch allows you to swing the handle all the way open, which physically lifts the locking pawl away from the gear, releasing the tension instantly.

How to Release Tension: Step-by-Step

Follow this sequence precisely. The entire process hinges on fully completing Step 2.

Step 1: Locate and Pull the Release Catch

Find the smaller spring-loaded lever, which is typically part of the main, padded handle assembly. Pull it with your fingers to disengage it from the gear wheel. You must keep this catch pulled during the next step.

Step 2: Open the Handle Until Completely Flat

While holding the release catch, swing the entire handle assembly away from the strap until it is in a fully open, 180-degree position. You may feel some resistance just before it opens flat; this is the mechanism disengaging.

Step 3: Pull the Strap Free

With the handle locked open and flat, the spool is now free to spin. Grab the loose end of the strap webbing and pull it backward through the spool to release your cargo.

Troubleshooting Common Problems

Even when you know the steps, high tension or a poorly wound strap can cause issues. Here is how to solve them.

The Handle Won't Open

If the strap is under extreme tension, the locking pawl is wedged tightly against the gear. It may require significant upward force on the release catch and handle to overcome the friction and force it open.

The Strap is Jammed and Won't Pull

This usually happens when the strap was wound unevenly or has bunched up on one side of the spool. Once you have the handle open, try a slight "see-saw" motion, pulling the spool a little tighter and then releasing it, to un-jam the bunched webbing.

The Release Catch Feels Stuck

Dirt, rust, or debris can impede the small springs in the mechanism. A quick spray of a lubricant like WD-40 can often free up a sticky release catch or pawl, making the entire process much smoother.

Making the Right Choice for Your Goal

Applying these principles correctly ensures safety and efficiency.

- If your primary focus is safety: Always ensure the load is stable on its own before releasing the tension, as the release can be sudden and cause the cargo to shift.

- If your primary focus is preventing future jams: When tightening, guide the strap so it winds onto the spool evenly and flat, avoiding twists or bunching on one side.

- If your primary focus is a fast, frustration-free release: Remember that the only thing that matters is getting the handle to a fully flat, 180-degree position; anything less will keep the mechanism locked.

By understanding that opening the handle flat is the key to lifting the lock, you can operate any ratchet strap with confidence and control.

Summary Table:

| Step | Action | Key Tip |

|---|---|---|

| 1 | Pull the Release Catch | Disengage the locking mechanism. |

| 2 | Open Handle Until Flat | The handle must be at a 180-degree position to lift the pawl. |

| 3 | Pull the Strap Free | Pull the webbing backward to release tension. |

Tired of struggling with jammed or unreliable ratchet straps? As HONESTBEE, we supply durable, easy-to-use ratchet straps and other essential beekeeping supplies to commercial apiaries and equipment distributors. Our wholesale-focused operations ensure you get high-quality equipment that performs reliably, saving you time and frustration. Contact us today to learn more about our products and wholesale pricing!

Visual Guide

Related Products

- Versatile Ratchet Hive Strap with S-Hooks for Secure Fastening

- Heavy Duty Ratchet Hive Strap

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Endless Loop Ratchet Hive Strap

- Heavy-Duty Galvanized Steel W-Style Pallet Clip

People Also Ask

- In what stages of field exploration for stingless bee nests are metal cutting tools primarily utilized? Access Prep Guide

- Why is a hive tool necessary? The Essential Key to Every Hive Inspection

- Why is the selection of standardized beekeeping tools critical? Ensure Success in Queen Rearing & Colony Splitting

- Why is use of professional bee colony monitoring tools necessary for ICP? Optimize Your Pollination Efficiency

- How are professional hive scrapers and fine precision tweezers used during the sample collection for bee parasites?

- What is the function of beehive transport and locking devices? Essential Gear for Migratory Beekeeping Success

- In what specific situation is the frame cleaning tool particularly useful? Master Cut Comb Maintenance

- What is the purpose of the holes found in hive tools? Unlock Hidden Efficiency in Your Apiary