At its core, using a honey warmer is a simple, patient process. You place your container of crystallized honey into the unit, set the thermostat to a low temperature—typically between 95°F and 110°F (35°C to 43°C)—and wait. Over a period of 12 to 48 hours, the gentle, consistent heat will re-liquefy the honey without damaging its natural qualities, making it ready for bottling or use.

The primary challenge is not simply melting honey, but doing so without destroying the delicate enzymes and complex flavors that make it a unique natural product. A honey warmer solves this by applying low, slow, and controlled heat—a method vastly superior to faster, high-heat alternatives that can degrade quality.

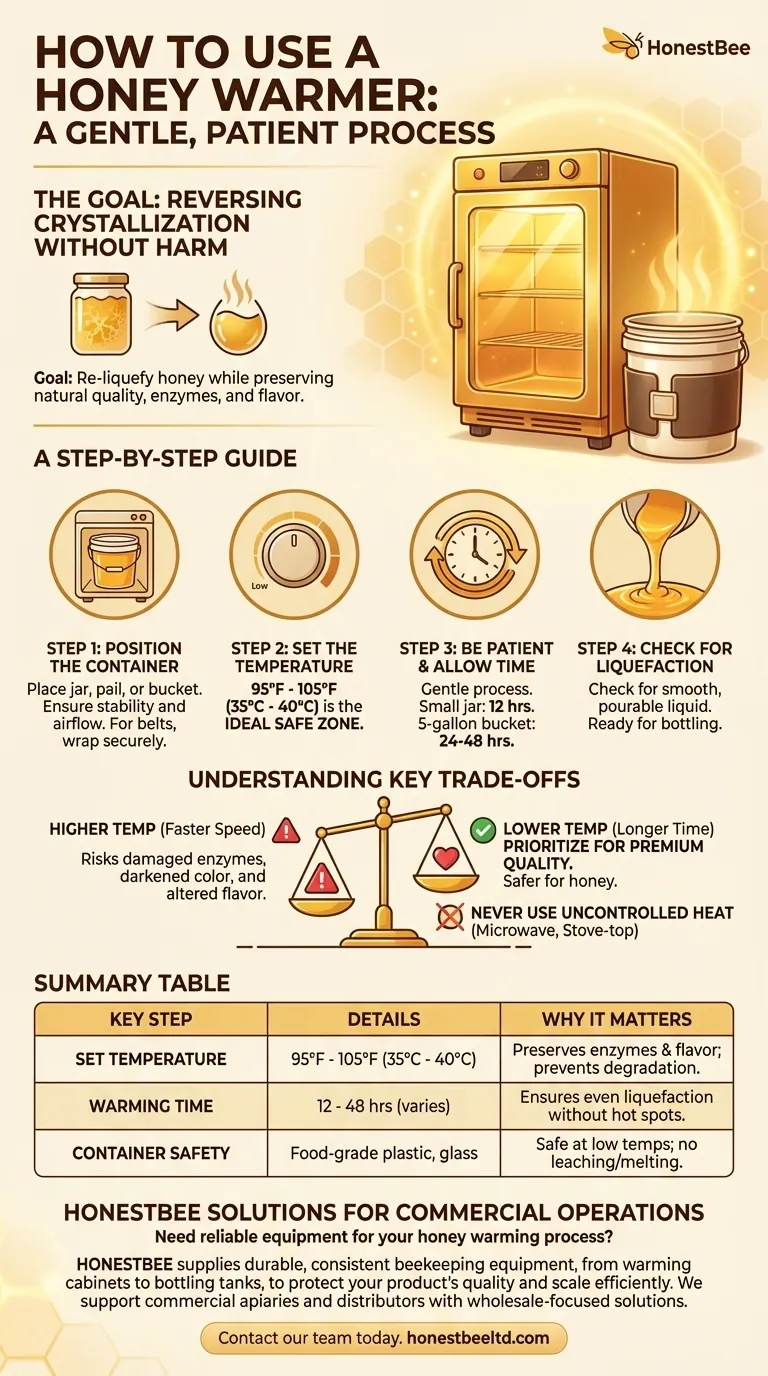

The Goal: Reversing Crystallization Without Harm

Before using a warmer, it's critical to understand what you are trying to achieve and why the method matters so much.

What is Honey Crystallization?

Crystallization, or granulation, is a completely natural process. Honey is a supersaturated solution of sugars, primarily glucose and fructose, in a small amount of water.

Over time, the glucose can separate from the water and form tiny crystals, causing the honey to become semi-solid. This is not a sign of spoilage; it simply indicates the honey is natural and unprocessed.

Why Gentle Heat is Critical

The goal is to dissolve those sugar crystals back into the solution. However, honey contains beneficial enzymes and volatile compounds that create its unique aroma and taste.

High heat (generally anything above 110°F or 43°C) can rapidly destroy these enzymes and "cook" the honey. This darkens its color, alters the flavor, and diminishes its beneficial properties.

Using Your Honey Warmer: A Step-by-Step Guide

Whether you have a wrap-around bucket heater or a full warming cabinet, the principles are identical.

Step 1: Position the Honey Container

Place your sealed jar, pail, or bucket of crystallized honey into the warming unit. Ensure it is stable and, in the case of a cabinet, has adequate airflow around it.

For belt-style warmers, wrap the belt securely around the midsection of the bucket.

Step 2: Set the Temperature

This is the most important step. Set the thermostat to a low temperature. A range of 95°F to 105°F (35°C to 40°C) is the ideal safe zone.

One beekeeper successfully used 100°F (38°C) to re-liquefy multiple buckets in an unheated building. This is an excellent, field-tested benchmark.

Step 3: Be Patient and Allow Time

Gentle warming is not a fast process. The time required depends on the size of the container, the degree of crystallization, and the ambient temperature.

- A small jar might re-liquefy in 12 hours.

- A 5-gallon (60 lb) bucket can easily take 24 to 48 hours.

Resist the temptation to increase the heat to speed things up. Patience is the key to preserving quality.

Step 4: Check for Liquefaction

After the recommended time, check the honey. It should be fully liquid, smooth, and pourable. Once liquefied, it is ready to be transferred to a bottling tank or used directly.

Understanding the Key Trade-offs

Using a honey warmer involves balancing speed, convenience, and quality.

Temperature vs. Time

This is the central trade-off. A higher temperature works faster but carries a significant risk of damaging the honey. A lower temperature is much safer for the honey's quality but requires more time.

For premium honey, always prioritize a lower temperature and a longer warming time.

The Dangers of Uncontrolled Heat

Never use a microwave, direct stove-top heat, or a pot of boiling water to warm honey. These methods are impossible to control.

They create intense hot spots that will scorch the honey, destroying its enzymes and flavor long before the entire container is melted. A dedicated warmer provides the gentle, consistent heat that is required.

Container Material

Food-grade plastic pails and buckets are perfectly safe to use in a honey warmer at these low, controlled temperatures. They will not leach chemicals or melt. Glass jars are, of course, also completely safe.

Making the Right Choice for Your Goal

Apply these principles based on your specific needs.

- If your primary focus is preserving raw honey quality: Always use the lowest effective temperature (95°F to 100°F) and plan for a 24-48 hour warming period for large containers.

- If your primary focus is bottling efficiency for large volumes: A dedicated warming cabinet that can hold multiple buckets is a necessary investment to ensure a consistent, reliable workflow.

- If you are a hobbyist with a few crystallized jars: A small warming mat or even the "proof" setting on some ovens can work, but you must use a separate thermometer to verify the temperature stays below 110°F.

Ultimately, using a honey warmer is an exercise in controlled patience, safeguarding the natural quality of the honey from the hive to the bottle.

Summary Table:

| Key Step | Details | Why It Matters |

|---|---|---|

| Set Temperature | 95°F to 105°F (35°C to 40°C) | Preserves delicate enzymes and flavor; prevents quality degradation. |

| Warming Time | 12 to 48 hours (depending on container size) | Gentle, consistent heat ensures even liquefaction without hot spots. |

| Container Safety | Food-grade plastic pails, buckets, or glass jars | Safe for use at low temperatures; no risk of leaching or melting. |

Need Reliable Equipment for Your Honey Warming Process?

As a commercial beekeeper or distributor, your honey's quality is your reputation. Efficiently managing large volumes requires durable, consistent equipment.

HONESTBEE supplies the beekeeping supplies and equipment you need for a seamless operation. We support commercial apiaries and beekeeping equipment distributors with wholesale-focused solutions, from warming cabinets to bottling tanks.

Let us help you protect your product's quality and scale your operation effectively.

Contact our team today to discuss your specific needs and our product offerings.

Visual Guide

Related Products

- Honey Tank Heater Drum Heating Blanket for Honey Barrel

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What is the primary function of specialized heating ovens for honey drums? Unlock Efficient Bulk Extraction

- Why are heating elements encapsulated in gypsum blocks? Ensure Safety and Stable Heat for Your Honeybee Hive Systems

- How does heating honey improve its processing? Unlock Efficient Bottling & Filtration

- How do you make Crystallised honey runny again? The Safe & Simple Guide to Restoring Liquid Honey

- What are the applications of digital thermostatic heating plates in honey pretreatment? Ensure Accurate Lab Analysis

- What are the methods for heating honey? Preserve Quality and Improve Workability

- What is the role of temperature control equipment in honey and beeswax trade? Ensure Pathogen-Free Global Exports

- Why is temperature control important for storing honey? Preserve Quality, Texture, and Nutritional Value