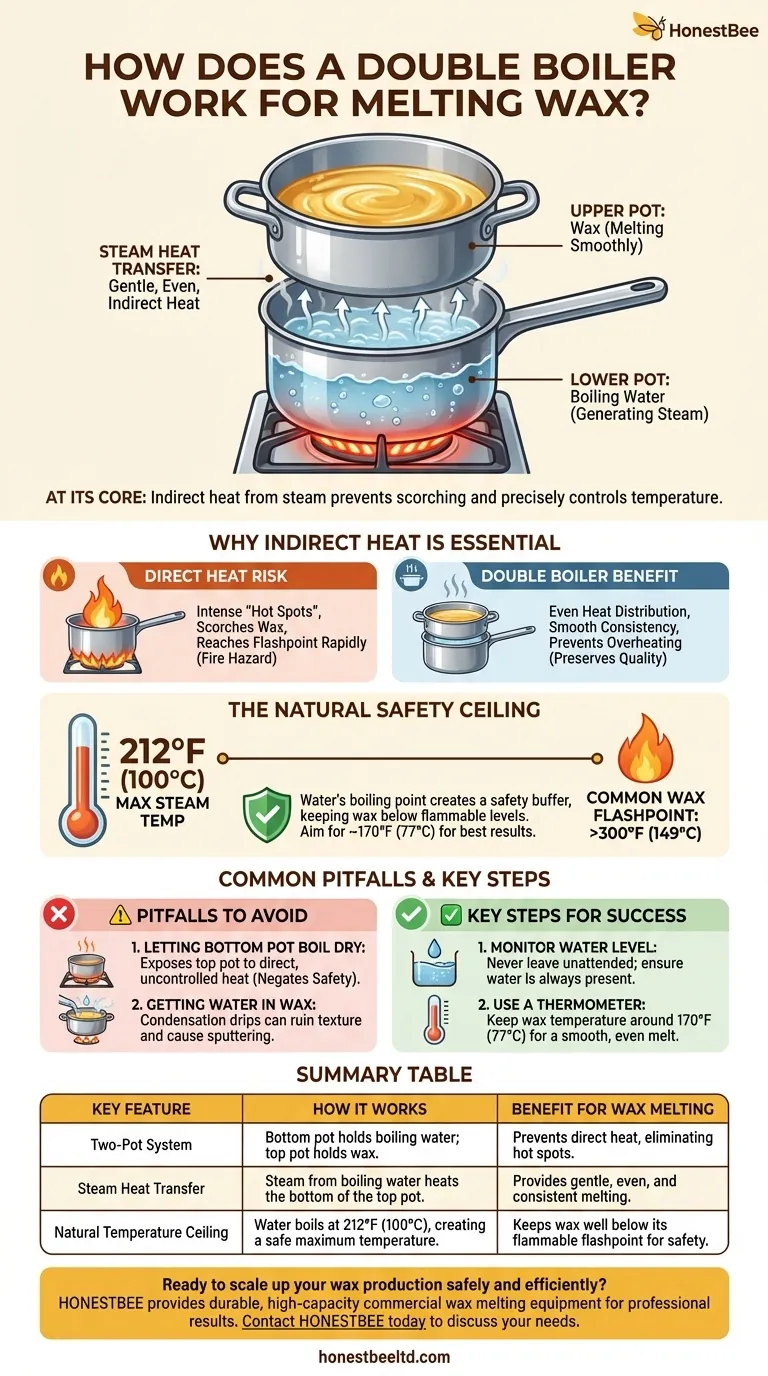

At its core, a double boiler melts wax using indirect heat. It is a two-part system where a lower pot of boiling water generates steam, and that steam gently and evenly heats an upper pot containing the wax. This method gives you precise control and prevents the wax from getting too hot too quickly.

The true purpose of a double boiler is not just to melt wax, but to do so safely. By using steam as the heat source, it naturally regulates the temperature, preventing the wax from scorching or reaching its flammable flashpoint.

Why Indirect Heat is Essential for Wax

The entire principle of the double boiler revolves around moving the heat source away from direct contact with the wax. This simple separation is critical for both quality and safety.

The Two-Pot System

A double boiler consists of two stacked pots. The bottom pot holds a few inches of water, and the top pot, which holds the wax, is nested securely above it.

This setup ensures the top pot is never touched by the direct flame or electric coil of your stove.

The Role of Steam

As you heat the bottom pot, the water turns to steam. This steam rises, making contact with the bottom surface of the upper pot and transferring its heat energy.

It is this gentle, consistent steam—not boiling water or a direct flame—that does the actual work of melting the wax.

Even and Gentle Melting

Direct heat from a stovetop creates intense "hot spots" on the bottom of a pan. This can easily scorch your wax, altering its color and texture.

The steam from a double boiler, however, envelops the bottom of the top pot, distributing heat evenly for a smooth, consistent melt.

The Primary Goal: Temperature Control and Safety

Melting wax isn't like melting butter; it involves a flammable material that must be handled with care. The double boiler is the standard tool for managing this risk.

Preventing Overheating

Wax can be damaged by excessive heat. The double boiler method keeps the temperature low and stable, preserving the integrity of the wax for its intended use, whether for candles, cosmetics, or waterproofing.

The Danger of the Flashpoint

Every type of wax has a flashpoint—the temperature at which it produces enough vapor to ignite if exposed to a flame. Heating wax directly in a pan can easily and rapidly push it past this point, creating a significant fire hazard.

The Water's Temperature Ceiling

The most brilliant safety feature of this method is the water itself. Water cannot get hotter than its boiling point of 212°F (100°C).

This creates a natural temperature ceiling. The steam will never exceed this temperature, which keeps the wax well below the flashpoint of most common waxes, which is typically above 300°F (149°C). For best results, you should still monitor the wax and aim for a temperature around 170°F (77°C).

Common Pitfalls to Avoid

While effective, this method requires attention to a few key details to avoid defeating its purpose.

Letting the Bottom Pot Boil Dry

This is the most critical mistake to avoid. If all the water in the bottom pot evaporates, the top pot is now exposed to direct, uncontrolled heat.

This completely negates the safety benefits of the double boiler and can quickly lead to scorched wax or a fire. Always ensure there is water in the bottom pot.

Getting Water in Your Wax

Be careful that steam does not condense and drip into your melting wax. Water contamination can ruin the texture of the final product and, in candle making, can cause dangerous sputtering when the wick is lit.

Key Steps for Safe and Effective Wax Melting

Use these principles to guide your process, whether you are using a dedicated double boiler or an improvised setup.

- If your primary focus is safety: Never leave melting wax unattended and always monitor the water level in the bottom pot to ensure it never boils dry.

- If your primary focus is quality: Keep the heat on medium-low and use a thermometer to keep your wax from exceeding 170°F (77°C) for a smooth, even melt.

- If you are improvising a setup: Choose a heat-proof bowl that rests securely on the lip of the bottom pot without touching the water below.

Mastering this simple technique grants you complete control over the process, ensuring safe and consistent results every time.

Summary Table:

| Key Feature | How It Works | Benefit for Wax Melting |

|---|---|---|

| Two-Pot System | Bottom pot holds boiling water; top pot holds wax. | Prevents direct heat, eliminating hot spots. |

| Steam Heat Transfer | Steam from boiling water heats the bottom of the top pot. | Provides gentle, even, and consistent melting. |

| Natural Temperature Ceiling | Water boils at 212°F (100°C), creating a safe maximum temperature. | Keeps wax well below its flammable flashpoint for safety. |

Ready to scale up your wax production safely and efficiently?

As a trusted supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-capacity wax melting equipment you need for professional results. Our wholesale-focused operations ensure you get the reliable tools for consistent, high-quality output.

Contact HONESTBEE today to discuss your commercial wax melting needs and explore our product solutions.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What is the effect of heating on honey? Preserve Quality with Controlled Warming

- How to permanently decrystallize honey? Embrace Its Natural State for Maximum Quality

- What is the water bath method for honey processing? A Gentle Technique for Quality Honey

- What are the negative effects of overheating honey? Preserve Your Honey's Natural Quality

- Is it safe to heat crystallized honey? Restore Your Honey's Liquid State Safely