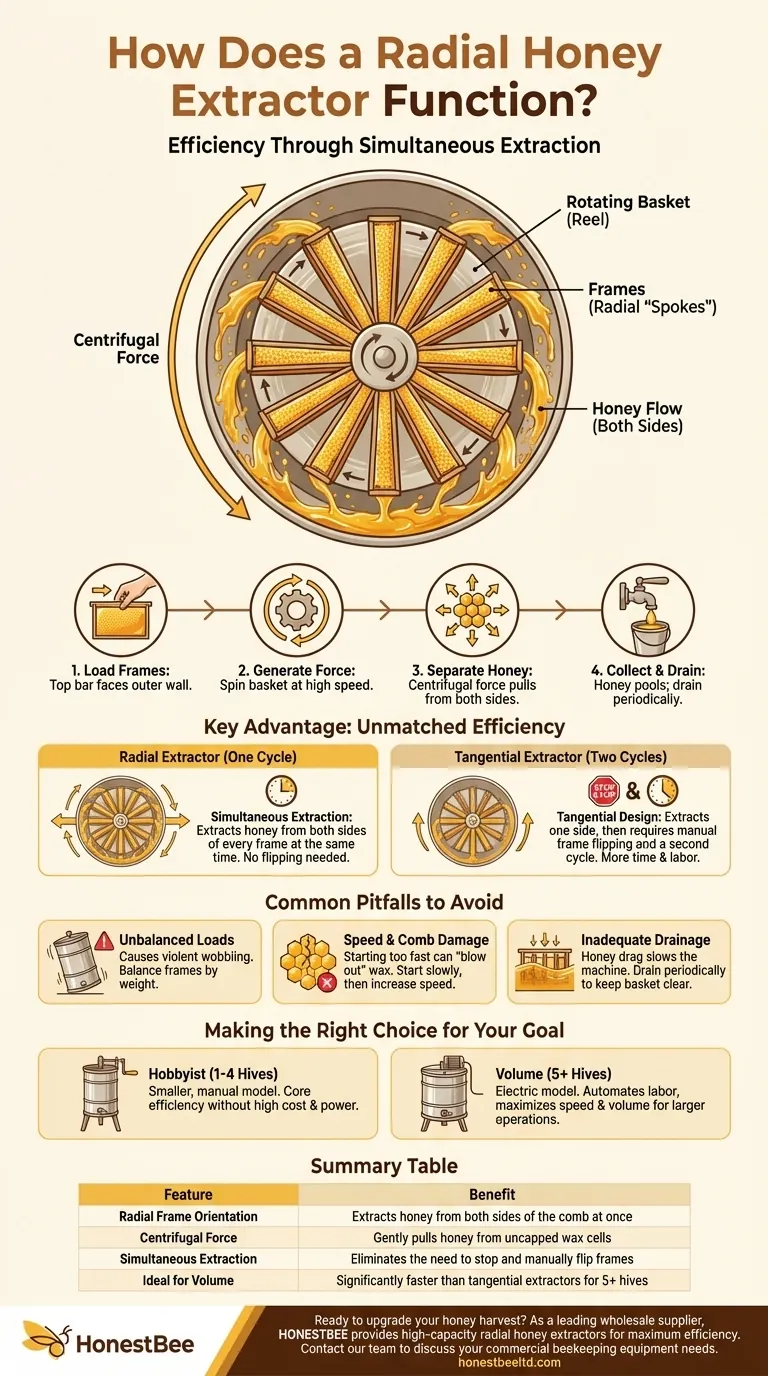

At its core, a radial honey extractor functions by positioning frames like the spokes of a wheel and using centrifugal force to extract honey from both sides of the comb simultaneously. This design is fundamentally about efficiency, as it eliminates the need to stop the process and manually flip each frame.

The defining characteristic of a radial extractor is its ability to extract honey from both sides of a frame at once. This single feature significantly reduces the time and labor required for honey harvesting compared to other designs.

The Mechanics of Centrifugal Extraction

A radial extractor, whether manual or electric, is a simple yet powerful machine that operates on a clear physical principle. Understanding each step in the process clarifies why its design is so effective.

The "Spokes of a Wheel" Configuration

Frames are loaded into a central rotating basket, or "reel." Crucially, they are oriented so the top bar of the frame faces the outer wall of the extractor drum. This positions the frames radially, much like the spokes extending from the hub of a wheel.

Generating Centrifugal Force

Once loaded, the basket is spun at high speed, either by a hand crank or an electric motor. This rotation generates centrifugal force, which acts to push anything inside the basket away from the center and towards the outer wall.

Separating Honey from Comb

As the frames spin, this powerful outward force pulls the honey directly out of the uncapped wax cells. Because of the frames' orientation, the honey is slung outwards from both sides of the comb in a single, continuous operation.

Collection and Drainage

The extracted honey splatters against the inner wall of the extractor's drum. Gravity then takes over, causing the honey to run down the walls and pool at the bottom. A tap or "honey gate" at the base allows for easy drainage into a bucket or filtration system.

The Key Advantage: Unmatched Efficiency

While all extractors use centrifugal force, the radial configuration provides a distinct advantage that makes it the standard for most serious beekeepers.

Simultaneous Extraction

The primary benefit is that honey is removed from both sides of every frame at the same time. You load the frames once and run the machine until they are empty.

Eliminating the Flip

This contrasts sharply with tangential extractors, which hold the frame flat against the outer wall. In a tangential design, only the outward-facing side is extracted, forcing the operator to stop the machine, flip every frame by hand, and run the cycle again.

Ideal for Larger Operations

This time-saving feature makes the radial design vastly more efficient. For anyone managing more than a few hives, the reduction in manual labor and processing time is a significant operational advantage.

Common Pitfalls to Avoid

While effective, operating a radial extractor requires attention to a few key details to ensure a smooth and successful harvest.

Unbalanced Loads

Placing frames with significantly different weights opposite each other can cause the extractor to wobble violently during operation. It's crucial to balance the load by placing frames of similar weight across from one another to ensure stable spinning.

Speed and Comb Damage

Starting the extractor at full speed, especially with delicate new comb, can cause the wax to "blow out" or be destroyed by the force. Best practice is to start slowly to extract the heaviest honey first, then gradually increase the speed.

Inadequate Drainage

Allowing extracted honey to pool too high in the drum is a common mistake. If the honey level reaches the spinning frames, it creates significant drag, slowing the machine and preventing an effective extraction. You must drain the honey periodically to keep the bottom of the basket clear.

Making the Right Choice for Your Goal

Selecting the right extractor depends entirely on the scale of your operation and your primary goals.

- If your primary focus is hobbyist beekeeping (1-4 hives): A smaller, manually-operated radial extractor provides the core efficiency of the design without the higher cost and power requirement of an electric model.

- If your primary focus is maximizing speed and volume (5+ hives): An electric radial extractor is the clear choice, as it automates the most labor-intensive part of the process and dramatically reduces harvesting time.

Ultimately, understanding the radial extractor's function empowers you to choose the right tool for a faster, more rewarding honey harvest.

Summary Table:

| Feature | Benefit |

|---|---|

| Radial Frame Orientation | Extracts honey from both sides of the comb at once |

| Centrifugal Force | Gently pulls honey from uncapped wax cells |

| Simultaneous Extraction | Eliminates the need to stop and manually flip frames |

| Ideal for Volume | Significantly faster than tangential extractors for 5+ hives |

Ready to upgrade your honey harvest?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides durable, high-capacity radial honey extractors designed for maximum efficiency and reliability. Our equipment helps large-scale operations save valuable time and labor during the busiest seasons.

Contact our team today to discuss your commercial beekeeping equipment needs and request a wholesale quote.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- Should I get a manual or electric honey extractor? Choose the right extractor for your beekeeping scale.

- How do automatic honey extractors function? Achieve High-Efficiency Honey Harvesting

- How to get honey out of a frame? Choose Between Crush & Strain or Centrifugal Extraction

- What is the purpose of decanting in honey extraction? Achieve a Purer, More Stable Honey Product

- How long does an electric honey extractor take? Drastically Cut Your Harvest Time & Effort