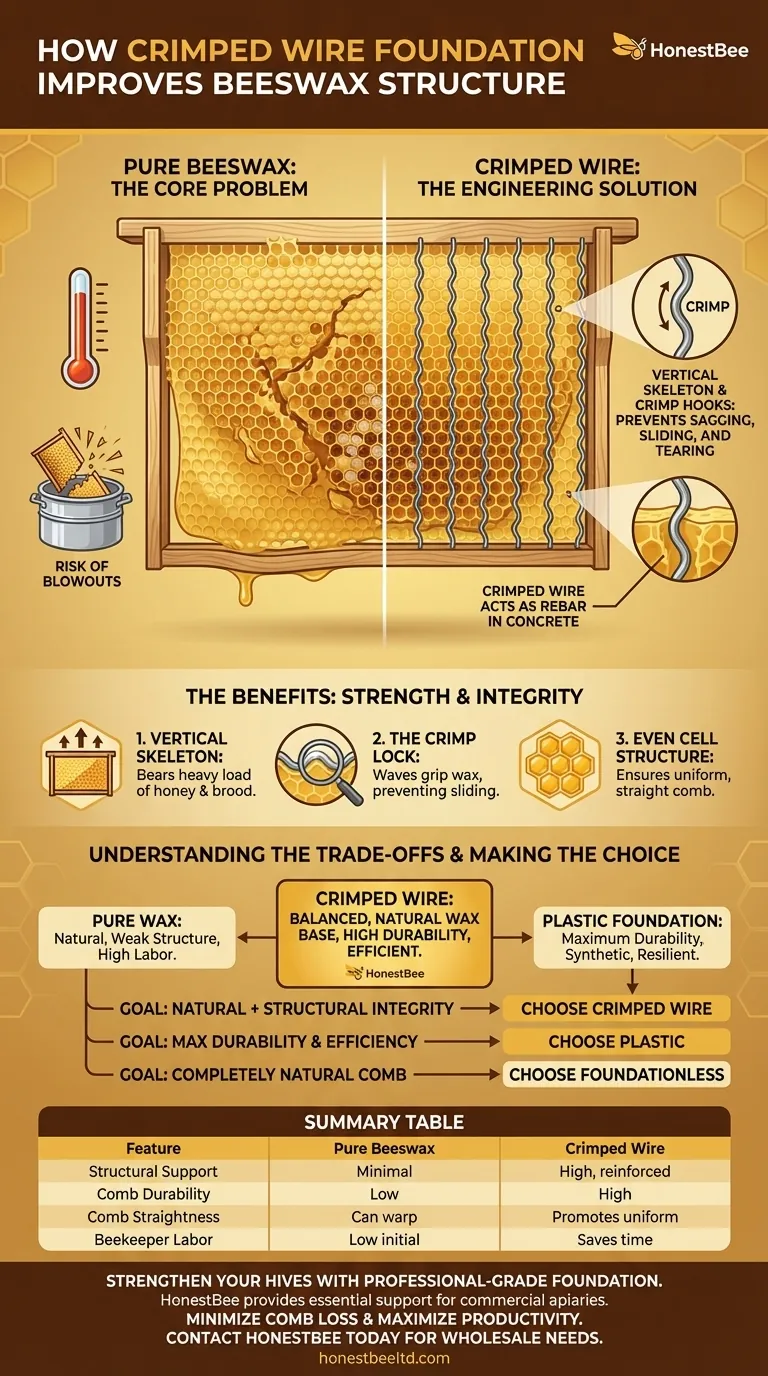

In short, crimped wire foundation improves the structure of pure beeswax by embedding a rigid vertical framework directly into the wax sheet. This internal "skeleton" provides critical support, preventing the soft wax from sagging, warping, or breaking under the immense weight of honey and brood, especially in warm conditions.

The core challenge with pure beeswax foundation is its structural weakness. Crimped wire serves as a reinforcement, much like rebar in concrete, offering a way to maintain the integrity of the comb without resorting to a fully plastic foundation.

The Core Problem: The Instability of Pure Beeswax

A sheet of pure beeswax foundation gives bees a head start, but the material itself has inherent limitations that can cause significant problems within the hive.

The Natural Softness of Wax

Beeswax is a remarkable material, but it is also soft and pliable. On hot summer days, the internal temperature of a hive can cause wax foundation to soften considerably.

Under its own weight, a warm sheet of wax can begin to stretch and sag, creating distorted cells that the bees may be unwilling to use.

The Weight of Honey and Brood

A bare foundation sheet is lightweight, but its purpose is to be a base for heavy contents. A single deep frame can hold over eight pounds (3.6 kg) of honey.

This concentrated weight puts enormous stress on the foundation. Without support, the wax can easily tear or separate from the top of the frame.

Risk of "Blowouts" During Extraction

The final test of a comb's strength comes during honey extraction. The centrifugal force used to spin honey out of the cells can easily shatter a weak or poorly supported comb.

This event, known as a "blowout," destroys the comb, wastes the bees' efforts, and creates a sticky mess for the beekeeper.

How Crimped Wire Provides a Solution

Embedding crimped wire is a simple yet highly effective engineering solution to the inherent weaknesses of beeswax.

Creating a Vertical Skeleton

The vertical wires act as a rigid internal frame. They bear the vertical load of the honey and brood, transferring the weight up into the wood frame itself.

This prevents the wax from stretching and sagging, ensuring the bees build a straight, even comb that is structurally sound.

The Importance of the "Crimp"

The wires are not straight for a crucial reason. The wave-like "crimp" dramatically increases the surface area of the wire and creates hundreds of small hooks.

These hooks grip the surrounding beeswax, preventing the sheet of wax from sliding down the smooth surface of the wire. This mechanical lock between the wire and the wax is the key to its effectiveness.

Ensuring Even Cell Structure

By preventing warping, the crimped wire foundation ensures the bees draw out uniform, correctly sized honeycomb cells.

This leads to stronger brood patterns and more efficient honey storage, contributing to the overall productivity and health of the colony.

Understanding the Trade-offs

While effective, crimped wire foundation is a compromise between two extremes. Understanding its position is key to making an informed choice.

Natural Wax vs. Maximum Durability

Crimped wire foundation is a step up in durability from foundationless or pure wax frames. It offers a more natural environment than plastic foundation, as the bees are still building on a base of 100% beeswax.

However, it is not as indestructible as a solid plastic foundation. High-speed extraction can still cause damage if the comb is not fully drawn out and attached to the frame walls.

The Alternative: Cross-Wiring

Some beekeepers prefer to install their own support wires, often in a horizontal or cross-wired pattern. This gives the beekeeper more control but requires additional labor and specialized tools like a wiring board and embedder.

Crimped wire foundation comes with the wiring pre-installed and embedded, offering a significant time-saving advantage.

Making the Right Choice for Your Hive

The best foundation depends entirely on your beekeeping philosophy and operational goals.

- If your primary focus is a natural hive with improved structural integrity: Crimped wire foundation is the ideal choice, balancing the benefits of a wax base with necessary support.

- If your primary focus is maximum durability and efficiency for a large operation: Molded plastic foundation is often more resilient to repeated, high-speed extractions.

- If your primary focus is a completely natural, bee-built comb: Foundationless frames or frames with small starter strips are the best option, but be prepared for more intensive hive management to ensure straight comb.

Ultimately, choosing the right foundation is about providing your bees with the best possible structure to meet your goals as a beekeeper.

Summary Table:

| Feature | Pure Beeswax Foundation | Crimped Wire Foundation |

|---|---|---|

| Structural Support | Minimal, prone to sagging | High, reinforced with a vertical wire skeleton |

| Comb Durability | Low, risk of tearing under weight | High, prevents blowouts during extraction |

| Comb Straightness | Can warp in heat | Promotes uniform, straight cell structure |

| Beekeeper Labor | Low initial setup | Saves time vs. self-wiring; no specialized tools needed |

Strengthen Your Hives with Professional-Grade Foundation

As a commercial beekeeper or equipment distributor, the structural integrity of your comb is critical to your operation's efficiency and honey yield. Crimped wire foundation from HONESTBEE provides the essential support your bees need to build strong, durable comb that can withstand the weight of honey and the forces of extraction.

We supply high-quality, pre-wired foundation in bulk to meet the demands of large-scale apiaries. Let us help you minimize comb loss and maximize productivity.

Contact HONESTBEE today to discuss your wholesale foundation needs and get a quote.

Visual Guide

Related Products

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Manual Spur Wheel Wire Embedder for Foundation

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- HONESTBEE Pneumatic Dual Wire Embedder for W-Pattern Foundation Wiring

- Professional Adjustable Timer Electric Wire Embedder

People Also Ask

- Why are hot wires or specialized cutting tools required for Top Bar Hive comb management? Master Hive Structural Integrity

- What is the final step in wiring a frame? Secure Lasting Tension for a Durable Hive

- How does the adoption of self-fertile almond varieties impact beekeeping equipment? Navigating the Strategic Shift

- What is the purpose of bee frame wire? Secure Wax Foundation and Reinforce Honeycomb

- What are the functions of wire-tensioning tools and wax foundation installation equipment in frame pretreatment?