At its core, the Auto Flow Hive enhances honey quality by creating a sealed, gentle, and precise extraction path from the comb directly to the jar. This innovative method bypasses the conventional, multi-step harvesting process, which significantly reduces the honey's exposure to environmental contaminants and processing stress. The result is a purer product that retains its most delicate flavors and aromas.

The Flow Hive's advantage for honey quality is not magic, but mechanics. By eliminating the disruptive and exposure-prone steps of traditional harvesting, it allows beekeepers to capture purer, more distinct honey with minimal stress on the colony.

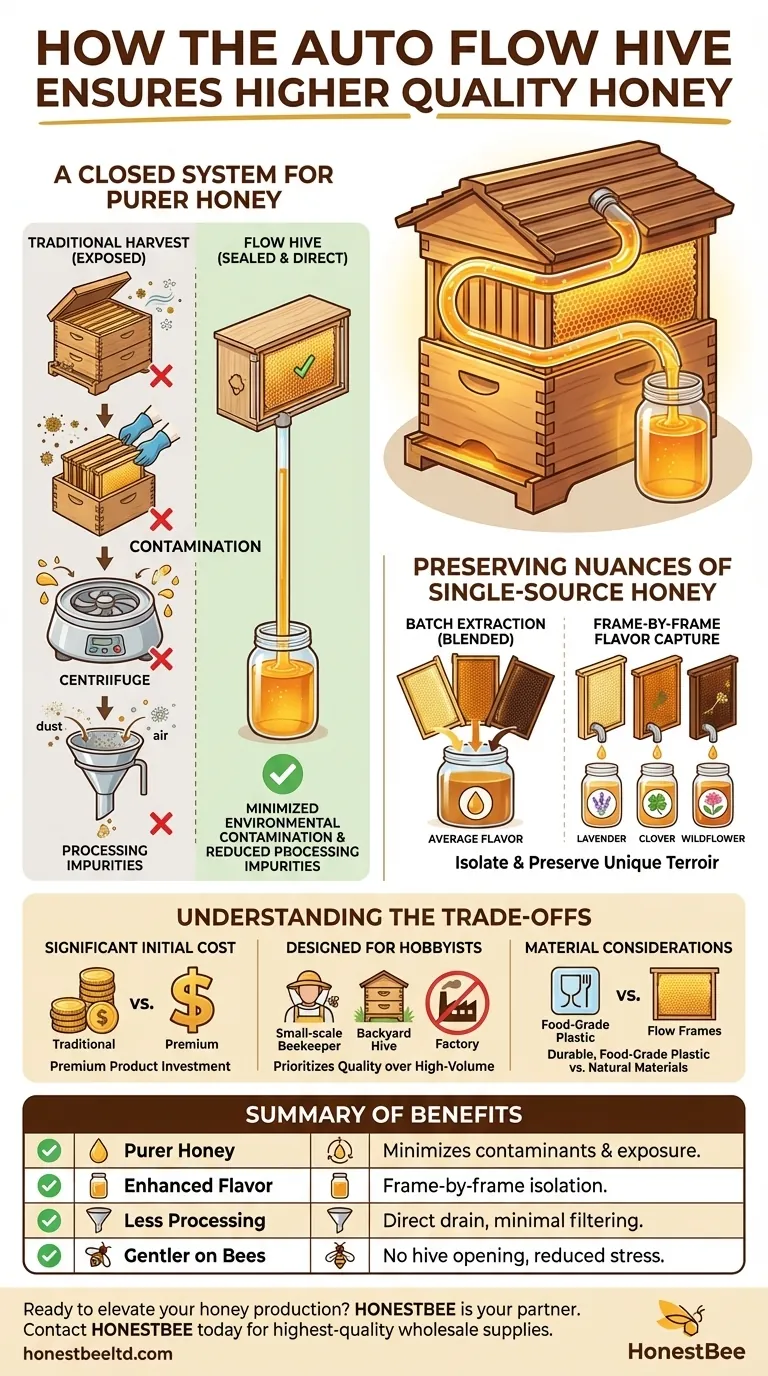

A Closed System for Purer Honey

The most significant impact on honey quality comes from the Flow Hive's fundamentally different extraction process. It creates a closed system that protects the honey from the moment it leaves the comb.

Minimizing Environmental Contamination

Traditional honey harvesting requires you to open the hive, remove the frames, and transport them to a separate location for extraction. Throughout this process, the honey is exposed to dust, pollen, air, and other potential contaminants.

The Flow Hive eliminates this exposure. The honey flows directly from the sealed comb through a protected tube and into your jar, ensuring it remains as clean as it was inside the hive.

Reducing Processing Impurities

Conventional methods involve uncapping wax, spinning frames in a centrifuge, and extensive filtering to remove wax particles and other debris. Each step can introduce small impurities.

Because the Flow Hive drains honey directly from the cells while leaving the wax cappings intact, the need for aggressive filtering is greatly diminished. This leads to exceptionally clean honey with minimal processing.

Preserving the Nuances of Single-Source Honey

For connoisseurs, honey quality is defined by flavor. The Flow Hive provides an unprecedented ability to isolate and preserve the unique taste of honey from a specific time and place.

The Problem with Batch Extraction

In a traditional harvest, honey from all frames is typically extracted and blended together. This averages out the flavors, masking the unique floral notes from a specific nectar flow (e.g., a week where the bees foraged exclusively on lavender).

Frame-by-Frame Flavor Capture

The Flow Hive allows a beekeeper to harvest honey one frame at a time. Bees often fill frames sequentially, meaning one frame might be full of light, early-season clover honey, while another is full of dark, late-season wildflower honey.

By tapping each frame individually, you can capture these distinct flavors in separate jars. This preserves the unique terroir and character of the honey, which is impossible with most conventional methods.

Understanding the Trade-offs

While the Flow Hive offers clear quality benefits, it is a specialized tool with specific trade-offs that must be considered.

The Significant Initial Cost

There is no avoiding the fact that Flow Hives are a premium product with a significantly higher initial cost compared to traditional Langstroth hives. This investment is primarily for the convenience and unique harvesting mechanism.

Designed for Hobbyists, Not Commercial Scale

The system is engineered for ease of use and small-scale production. Its design prioritizes quality and a gentle experience over the high-volume output required for large commercial operations, where traditional methods remain more cost-effective and efficient at scale.

Material Considerations

The patented Flow Frames are made of durable, food-grade plastic. While this is essential for their function, some beekeeping purists prefer to use only natural materials like wood and beeswax inside their hives.

Making the Right Choice for Your Goal

The decision to use a Flow Hive depends entirely on what you want to achieve with your beekeeping.

- If your primary focus is producing artisanal, small-batch honey with distinct flavors: The Flow Hive's frame-by-frame harvesting is its single greatest strength for achieving this.

- If your primary focus is ease of use and a low-stress experience for you and the bees: The system is explicitly designed for a simpler, less disruptive, and less labor-intensive harvest.

- If your primary focus is minimizing initial investment or running a larger operation: Traditional hive methods remain the more cost-effective and scalable industry standard.

Ultimately, the Flow Hive provides a specialized tool for beekeepers who prioritize honey purity, flavor fidelity, and a harmonious relationship with their colony.

Summary Table:

| Benefit | How the Flow Hive Achieves It |

|---|---|

| Purer Honey | Creates a closed system for extraction, minimizing exposure to dust, air, and contaminants. |

| Enhanced Flavor | Allows frame-by-frame harvesting to isolate and preserve unique, single-source honey flavors. |

| Less Processing | Drains honey directly from cells, reducing the need for aggressive filtering and preserving natural qualities. |

| Gentler on Bees | Enables harvesting without opening the hive or removing frames, significantly reducing colony stress. |

Ready to elevate your honey production? Whether you're a hobbyist aiming for artisanal quality or a distributor seeking innovative equipment for your customers, HONESTBEE is your partner. We supply commercial apiaries and beekeeping equipment distributors with the highest-quality wholesale supplies. Contact HONESTBEE today to discover how our equipment can help you achieve a purer, more profitable harvest.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- What are the advantages of using a Flow Hive? Simplifying Harvesting for Modern Beekeepers

- How do bees use Flow Frames? A Guide to Stress-Free Honey Harvesting

- How long does it take to get honey from a Flow Hive? Fast Harvesting Explained

- Why does the Flow Hive have a higher initial cost compared to conventional beehives? Is the Investment Worth It?

- Does using a hive with integrated flow frames reduce the beekeeper's workload? The Truth About Colony Management

- What are the technical purposes of transparent plastic channels and baffle structures in an automated beehive monitoring system?

- How long before a flow hive produces honey? Realistic Timelines for New & Established Hives

- How does the process of inspecting honey supers differ between a Flow Hive and a Langstroth hive? Manual vs Visual.