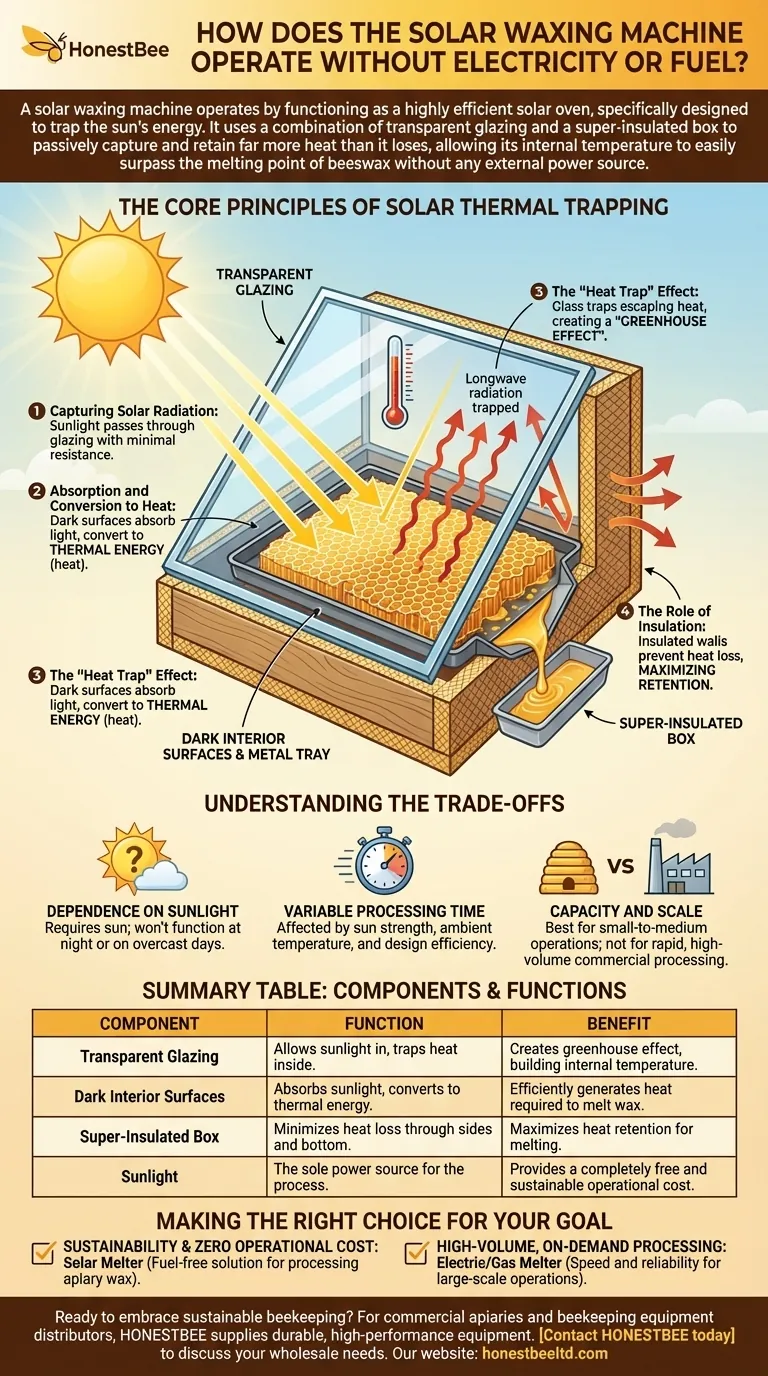

A solar waxing machine operates by functioning as a highly efficient solar oven, specifically designed to trap the sun's energy. It uses a combination of transparent glazing and a super-insulated box to passively capture and retain far more heat than it loses, allowing its internal temperature to easily surpass the melting point of beeswax without any external power source.

The device works by leveraging a simple but powerful principle: maximizing solar energy absorption while minimizing heat loss. This creates an environment that passively reaches and exceeds the melting point of beeswax using only the power of the sun.

The Core Principles of Solar Thermal Trapping

To understand how a solar melter works, you need to grasp how it manipulates two fundamental forces: solar radiation and heat retention. These devices are engineered to be excellent at absorbing energy and terrible at letting it go.

Capturing Solar Radiation

The process begins with the large glass pane, often called the glazing. Sunlight, which is a form of shortwave radiation, passes directly through the glass with very little resistance.

The angle of this glass is also intentional. It is positioned to face the sun as directly as possible, maximizing the amount of solar energy that enters the box throughout the day.

Absorption and Conversion to Heat

Once inside, the sunlight strikes the dark interior surfaces, particularly the metal tray holding the honeycomb. Dark, matte surfaces are exceptionally good at absorbing light energy and converting it into thermal energy, or heat.

This converted heat (longwave radiation) is what actually does the work of melting the wax.

The "Heat Trap" Effect

Here is the critical step. The glass that let the shortwave sunlight in is not nearly as transparent to the longwave heat radiation trying to escape.

This creates a "heat trap" or greenhouse effect. Energy can get in easily but has a very difficult time getting out, causing the temperature inside the box to build continuously.

The Role of Insulation

The final piece of the puzzle is the thick, insulated walls of the box itself. While the glass top prevents heat from radiating out, the insulated body prevents it from conducting out through the sides and bottom.

This insulation is crucial for efficiency, ensuring that the captured heat stays inside to melt the wax rather than bleeding out into the surrounding air.

Understanding the Trade-offs

While effective and sustainable, this technology is not without its limitations. Understanding them is key to using it successfully.

Dependence on Sunlight

The most obvious limitation is its complete reliance on the sun. The melter will not function at night, on heavily overcast days, or during periods of weak solar intensity.

Variable Processing Time

Unlike a powered device with a thermostat, a solar melter's performance is variable. The time it takes to melt a batch of wax depends entirely on the strength of the sun, the ambient air temperature, and the efficiency of the specific design.

Capacity and Scale

Solar wax melters are typically best suited for small- to medium-scale beekeepers. For large commercial operations that require rapid, predictable, high-volume processing, a fuel or electric-powered alternative is often more practical.

Making the Right Choice for Your Goal

By understanding its principles and limitations, you can determine if a solar melter fits your needs.

- If your primary focus is sustainability and zero operational cost: A solar melter is an unparalleled, fuel-free solution for processing wax from your apiary.

- If your primary focus is high-volume, on-demand processing: An electric or gas-powered melter will provide the speed and reliability needed for a larger-scale operation, especially in regions with inconsistent sunshine.

Ultimately, the solar wax melter is a powerful demonstration of how thoughtful design can harness natural energy to perform a valuable task.

Summary Table:

| Component | Function | Benefit |

|---|---|---|

| Transparent Glazing | Allows sunlight (shortwave radiation) in, traps heat (longwave radiation) inside. | Creates a greenhouse effect, building internal temperature. |

| Dark Interior Surfaces | Absorbs sunlight and converts it into thermal energy (heat). | Efficiently generates the heat required to melt the wax. |

| Super-Insulated Box | Minimizes heat loss through the sides and bottom of the machine. | Maximizes heat retention, ensuring energy is used for melting. |

| Sunlight | The sole power source for the entire melting process. | Provides a completely free and sustainable operational cost. |

Ready to embrace sustainable beekeeping?

For commercial apiaries and beekeeping equipment distributors, HONESTBEE supplies the durable, high-performance equipment you need to operate efficiently at scale. Our wholesale-focused operations ensure you get the best value on solar wax melters and other essential beekeeping supplies.

Contact HONESTBEE today to discuss your wholesale needs and discover how our solutions can enhance your sustainability and profitability.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards