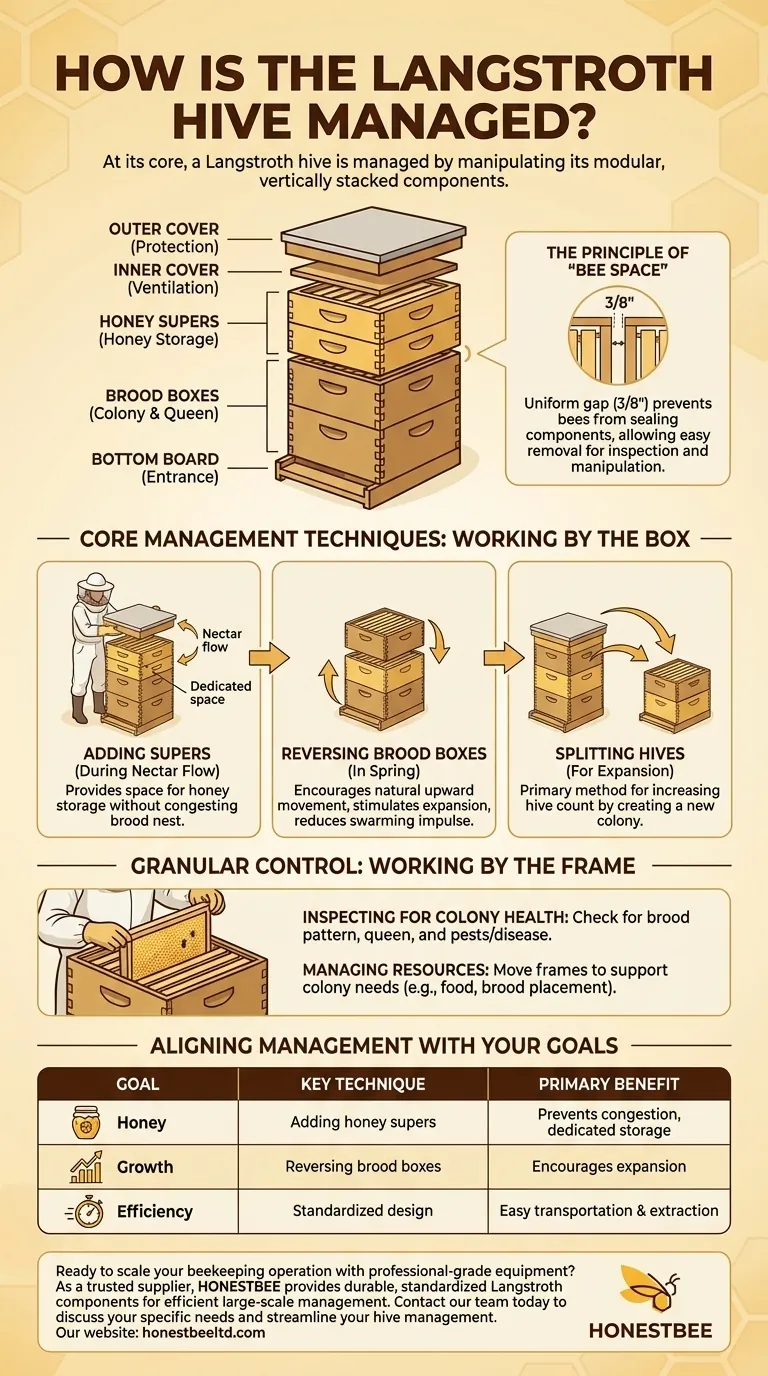

At its core, a Langstroth hive is managed by manipulating its modular, vertically stacked components. Beekeepers can manage the hive on a large scale by adding, removing, or rearranging entire boxes, or on a granular level by inspecting and moving individual frames within those boxes. This flexibility allows for precise control over colony expansion, health, and honey production.

The Langstroth system is effective because it is designed around the concept of "bee space." This specific spacing between frames and boxes prevents bees from sealing components together, enabling beekeepers to easily manage the colony with minimal disruption.

The Foundation: Understanding the Langstroth Design

The hive's management strategy is a direct result of its physical structure. Understanding these components is the first step to effective management.

The Core Components

A standard Langstroth hive consists of a bottom board, which serves as the floor and entrance. Above this sits one or more brood boxes (deeps), where the queen lays eggs and the colony raises its young.

As the colony grows and needs space for honey, shallower boxes called honey supers are stacked on top. An inner cover provides ventilation and a top entrance, and an outer cover protects the hive from the elements.

The Principle of 'Bee Space'

The genius of the design is the uniform gap—typically 3/8 of an inch—maintained between every frame and box wall. Bees will not build comb in a space this size, nor will they seal it with propolis.

This "bee space" is what makes the frames and boxes removable. It allows the beekeeper to conduct inspections and manipulate the hive without destroying the bees' work.

Core Management Techniques: Working by the Box

Much of the seasonal work in a Langstroth hive involves managing entire boxes to influence the colony's behavior and prepare for honey collection.

Adding Supers for Honey Production

During a nectar flow (a period when flowers are producing abundant nectar), the beekeeper adds honey supers on top of the brood boxes. This gives the bees dedicated space to store and cure honey without congesting the brood nest.

Reversing Brood Boxes

In the spring, colonies that have overwintered in two brood boxes often have the main cluster in the top box. By reversing the boxes—placing the top box on the bottom and the bottom box on top—the beekeeper encourages the bees' natural upward movement, stimulating expansion and reducing the impulse to swarm.

Splitting Hives for Expansion

A strong, populous hive can be split to create a new colony. This is done by moving a box containing frames of brood, honey, and bees to a new location and introducing a new queen. This is a primary method for increasing the number of hives in an apiary.

Granular Control: Working by the Frame

While box-level management is for broad strokes, frame-level inspection is for detailed diagnostics and fine-tuning.

Inspecting for Colony Health

The ability to remove individual frames is critical for assessing colony health. Beekeepers regularly pull frames to check for a healthy brood pattern, find the queen, and look for signs of pests like varroa mites or diseases.

Managing Resources

Frames can be moved between boxes to support the colony's needs. For example, a frame of honey can be moved down into a brood box to provide food, or a frame of brood can be moved up to encourage bees to start working in a new honey super.

Understanding the Trade-offs

The Langstroth system is the industry standard for a reason, but it is not without its challenges and requires a specific commitment from the beekeeper.

Weight and Labor

A deep brood box full of bees, brood, and honey can weigh over 80 pounds. Honey supers can also be quite heavy, making box-level management a physically demanding task. This has led to the popularity of 8-frame equipment, which is lighter than the traditional 10-frame setup.

The Need for Regular Inspection

The modularity of the Langstroth hive is a benefit, but it also means the colony requires active management. Unlike more "hands-off" hive types, a Langstroth hive must be inspected regularly to prevent swarming, manage space, and monitor health.

Standardization and Equipment

While standardized sizes are a major advantage for sourcing parts and mechanizing honey extraction, they also lock you into a specific system. Components from a 10-frame hive are not compatible with an 8-frame hive, requiring a consistent investment in one system.

Aligning Management with Your Goals

How you manage your Langstroth hive should be directly tied to what you want to achieve as a beekeeper.

- If your primary focus is maximizing honey production: You will actively add and manage honey supers during nectar flows and may consolidate resources from weaker hives to stronger ones.

- If your primary focus is colony health and population growth: You will perform regular frame-by-frame inspections to monitor for pests and disease and be prepared to split strong hives to expand your apiary.

- If your primary focus is operational efficiency (for commercial scale): You will leverage the uniform box design for easy transportation, palletizing, and the use of mechanized honey extraction equipment.

Mastering the Langstroth hive is about using its intelligent, modular design to support the natural lifecycle and productivity of your bees.

Summary Table:

| Management Goal | Key Technique | Primary Benefit |

|---|---|---|

| Maximize Honey Production | Adding honey supers during nectar flows | Prevents congestion, provides dedicated storage space |

| Prevent Swarming & Stimulate Growth | Reversing brood boxes in spring | Encourages upward colony expansion |

| Expand Apiary (Create New Colonies) | Splitting strong hives | Increases hive count, manages population |

| Monitor Health & Resources | Inspecting and moving individual frames | Assesses brood pattern, checks for pests/disease |

Ready to scale your beekeeping operation with professional-grade equipment?

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, standardized Langstroth components you need for efficient large-scale management. Our wholesale-focused operations ensure you get reliable equipment—from deep brood boxes to honey supers—that supports your honey production and colony health goals.

Contact our team today to discuss your specific needs and streamline your hive management.

Visual Guide

Related Products

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Telescopic Beehive Outer Cover Lid Roof with Galvanised Sheeting for Langstroth Hive and Beehive Outer Cover

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- What are the specific environmental challenges of using a horizontal Top Bar hive in cold climates? Survival Strategies

- What are the technical and maintenance characteristics of the Top Bar Hive in commercial beekeeping? Key Insights

- What are the ergonomic and management advantages of Horizontal Top-Bar Hives? Modern Beekeeping with Less Strain

- What are the benefits of the top bar hive? A Guide to Ergonomic, Natural Beekeeping

- How does the top bar hive help control varroa mites? A Natural Approach to Mite Management