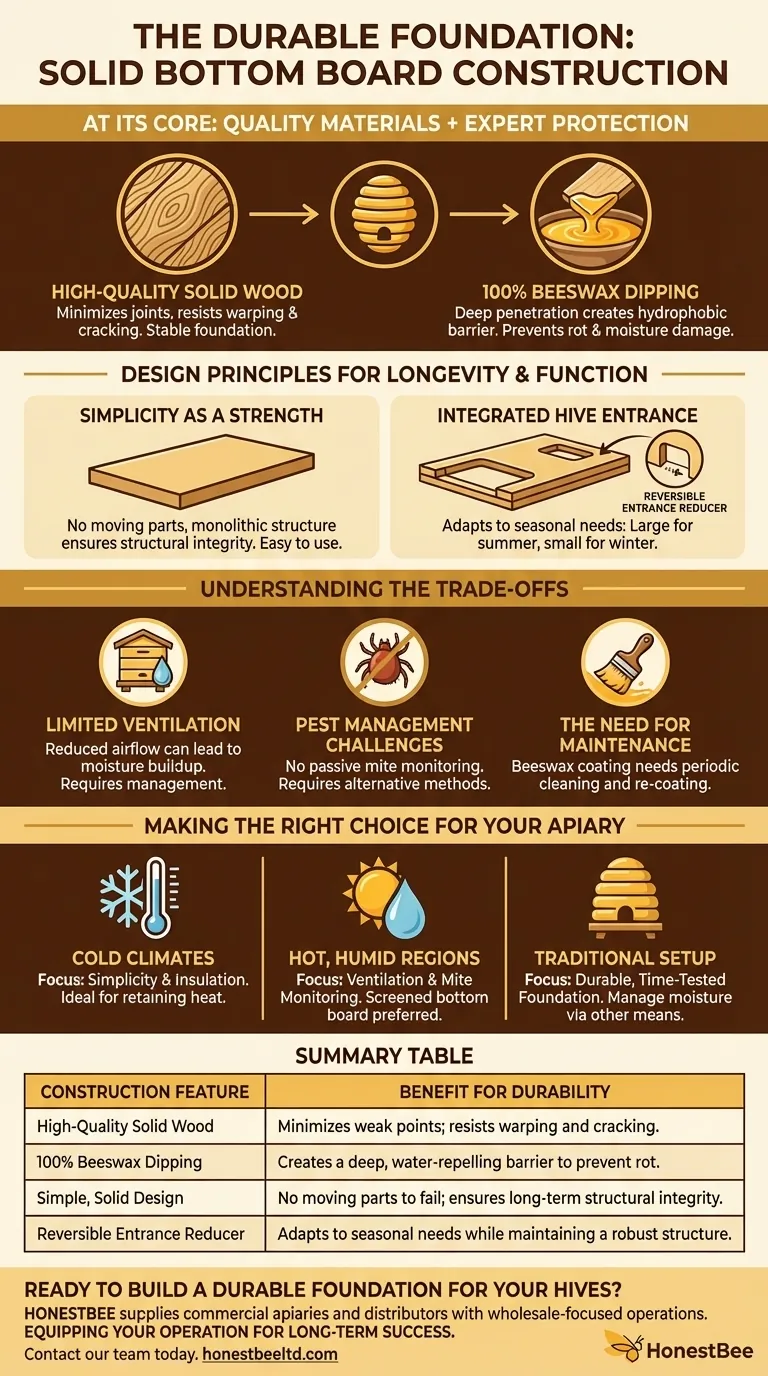

At its core, a solid bottom board's durability is achieved by combining two critical elements: the selection of high-quality wood and a protective treatment of 100% pure beeswax. This construction creates a robust foundation for the hive that is specifically designed to resist moisture, prevent rot, and withstand environmental stress for many years.

The simplicity of the solid bottom board is its greatest strength. Its durability hinges not on complex engineering, but on the fundamental principle of using quality materials and sealing them completely from moisture, the primary enemy of any wooden hive component.

The Core Components of Durability

To understand why a solid bottom board lasts, we must look at its two primary construction factors: the wood itself and the way it is protected.

The Role of High-Quality Wood

The process begins with the selection of high-quality, solid wood. This is not merely a cosmetic choice. Using a single, solid piece of lumber minimizes joints and seams, which are natural weak points where moisture can penetrate and decay can begin.

This choice of material provides dimensional stability, reducing the risk of the board warping, cracking, or twisting when exposed to fluctuations in temperature and humidity.

The Beeswax Dipping Process

The key to long-term endurance is the 100% beeswax dipping process. Unlike simply painting the surface, dipping the entire board in hot beeswax allows the wax to penetrate deep into the wood grain.

This saturation creates a hydrophobic (water-repelling) barrier from the inside out. It effectively seals the wood, making it non-porous and highly resistant to rain, snow, and ground moisture, which are the leading causes of rot and fungal growth.

Design Principles for Longevity and Function

Beyond the materials, the functional design of a solid bottom board contributes to its role as a stable and long-lasting hive foundation.

Simplicity as a Strength

The board's design is solid and straightforward. There are no moving parts or complex assemblies that can fail over time. This monolithic construction ensures structural integrity and makes it exceptionally easy to use and install.

Integrated Hive Entrance

A solid bottom board typically includes an integrated entrance, often with a reversible entrance reducer. This allows for a larger opening during summer for ventilation and high nectar flow, and a smaller opening during winter to help the colony defend against pests and conserve heat.

Understanding the Trade-offs

While highly durable, the solid bottom board is not the right choice for every situation. Its primary strength—being solid—also creates its main limitation.

Limited Ventilation

The most significant trade-off is reduced ventilation compared to a screened bottom board. The solid surface does not allow for air circulation from below, which can lead to moisture and condensation buildup inside the hive, especially in humid climates or during winter.

Pest Management Challenges

A solid bottom board does not offer the passive varroa mite monitoring benefits of a screened bottom. With a screened board, beekeepers can place a sticky board underneath to easily count mite drop. With a solid board, alternative monitoring methods are required.

The Need for Maintenance

While the beeswax coating is exceptionally durable, it is not permanent. Depending on the climate and exposure, the board may need to be cleaned and re-coated with beeswax every few years to maintain its protective seal.

Making the Right Choice for Your Apiary

The decision between a solid or screened bottom board depends entirely on your local climate and beekeeping goals.

- If your primary focus is simplicity and maximum insulation: A solid bottom board is an excellent choice, especially in colder climates where retaining hive heat is critical for winter survival.

- If your primary focus is ventilation and mite monitoring: You will be better served by a screened bottom board, particularly if you operate in a hot, humid region.

- If your primary focus is a durable, traditional setup: The solid bottom board offers a time-tested, robust foundation, provided you manage internal hive moisture through other means like upper entrances or quilt boxes.

Understanding these construction principles allows you to choose the foundation that best serves your climate, your management style, and the long-term health of your colony.

Summary Table:

| Construction Feature | Benefit for Durability |

|---|---|

| High-Quality Solid Wood | Minimizes weak points; resists warping and cracking. |

| 100% Beeswax Dipping | Creates a deep, water-repelling barrier to prevent rot. |

| Simple, Solid Design | No moving parts to fail; ensures long-term structural integrity. |

| Reversible Entrance Reducer | Adapts to seasonal needs while maintaining a robust structure. |

Ready to build a durable foundation for your hives? The construction principles of a solid bottom board—quality materials and expert protection—are the same standards we apply to all HONESTBEE supplies. We supply commercial apiaries and beekeeping equipment distributors with wholesale-focused operations. Let us help you equip your operation for long-term success. Contact our team today to discuss your needs!

Visual Guide

Related Products

- Langstroth Solid Bottom Board for Beekeeping

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- HONESTBEE Classic Pry Bar Hive Tool with High Visibility Finish for Beekeeping

- Professional Insulated Winter Hive Wrap for Beekeeping

People Also Ask

- What is the purpose of a solid bottom board in a hive? Essential for Winter Survival & Insulation

- What are the characteristics of a solid bottom board? A Guide to Hive Foundation & Climate Control

- What are the characteristics and uses of a solid bottom board? Essential Guide to Hive Insulation and Durability

- What is the primary function of a solid bottom board on a beehive? Key Benefits for Hive Stability and Insulation

- How are wooden bottom boards for beehives typically constructed? Durable Design Guide for Commercial Success