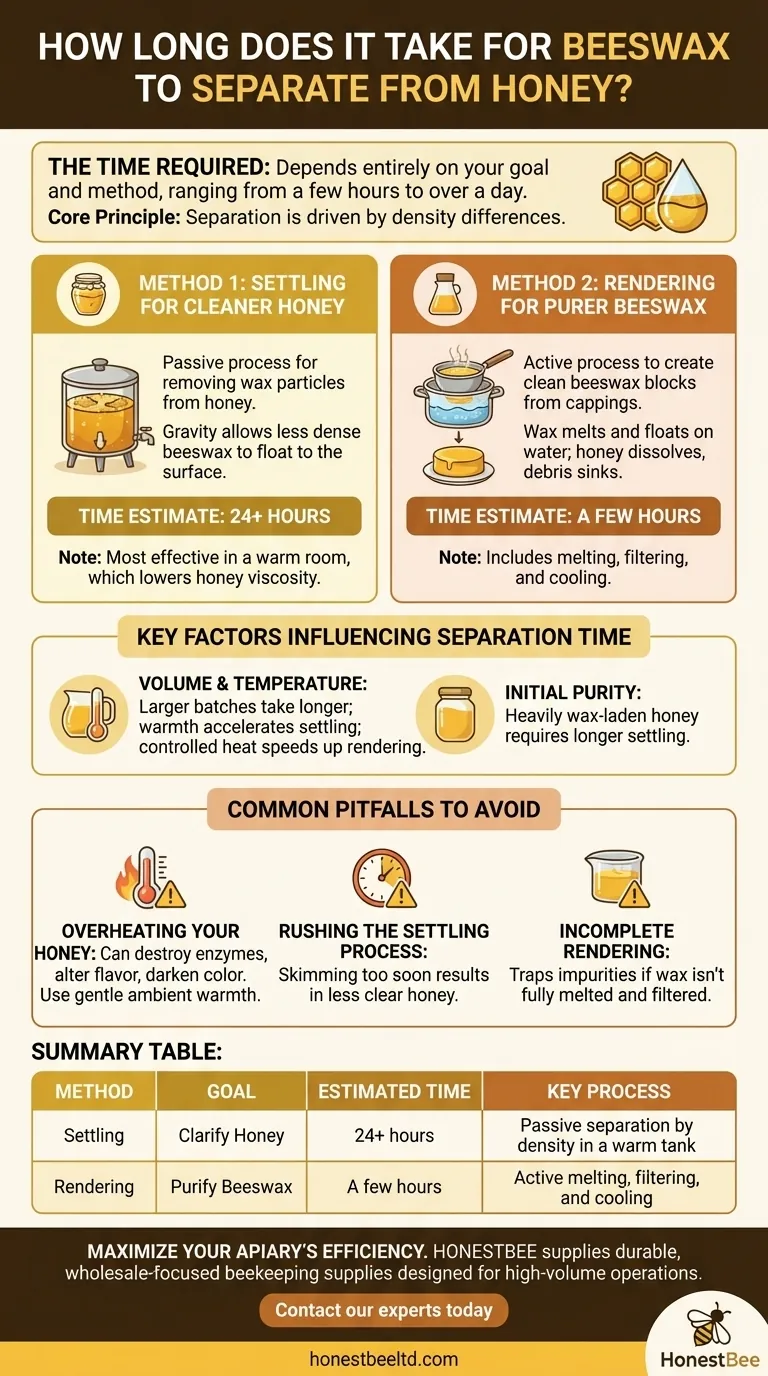

The time required for beeswax to separate from honey depends entirely on your goal and method, ranging from a few hours to over a day. For clarifying honey, a passive settling process can take 24 hours for wax particles to rise. For purifying the wax itself, an active rendering process of melting and cooling typically takes a few hours from start to finish.

The core principle is that separation is driven by density differences. Whether you are patiently letting wax float to the top of honey or actively melting wax to remove it from water, the timeframe is dictated by the technique you employ.

Two Primary Methods for Separation

Understanding the separation process begins with identifying your primary goal: are you trying to purify the honey or purify the beeswax? Each objective has its own distinct and effective method.

Method 1: Settling for Cleaner Honey

This is a passive method focused on removing small wax particles and other impurities from your liquid honey after extraction.

The honey is placed in a container, often called a settling tank, and simply left to sit. Gravity does all the work.

Because beeswax is less dense than honey, any suspended particles will slowly float to the surface over time. This process is most effective in a warm room, which lowers the honey's viscosity and allows the wax to rise more easily.

This can take anywhere from several hours to a full day, or even longer for larger volumes or cooler temperatures.

Method 2: Rendering for Purer Beeswax

This active method is used to process the wax cappings and other wax collected during extraction to create clean blocks of beeswax.

The wax is melted, typically in a double boiler or a dedicated wax melter, often with water.

As the mixture heats, the wax melts and floats on top of the water because it is lighter. The residual honey dissolves into the water, and heavier debris sinks to the bottom.

After melting and filtering through a fine mesh or cheesecloth, the mixture is allowed to cool. The pure wax solidifies into a clean cake on top, which can be easily lifted off once solid. This entire process usually takes a few hours.

Key Factors Influencing Separation Time

Several variables can accelerate or slow down the separation process, regardless of the method you choose.

Volume and Temperature

The larger the batch of honey or wax, the longer it will take to either settle or melt and cool completely. Temperature is the most significant accelerator; a warm environment drastically speeds up settling, while direct (but controlled) heat is essential for rendering.

Initial Purity

The amount of wax and debris in your initial honey harvest plays a role. Honey that is heavily laden with wax particles will naturally require a longer settling period to achieve clarity.

Common Pitfalls to Avoid

Achieving a clean separation requires patience and attention to detail. Rushing the process or using improper techniques can compromise the quality of both your honey and your wax.

Overheating Your Honey

When using warmth to speed up settling, it is critical not to overheat the honey. Excessive heat can destroy beneficial enzymes, alter the flavor, and darken the color of your final product. Gentle, ambient warmth is all that is needed.

Rushing the Settling Process

Skimming the wax off the honey too soon will result in a less clear product. For the best results, you must allow enough time for even the smallest particles to rise to the surface.

Incomplete Rendering

When rendering beeswax, ensure the wax is fully melted and properly filtered before it cools. Failing to do so can trap honey, water, and other impurities within the final block of wax, requiring you to repeat the process.

Making the Right Choice for Your Goal

Your intended outcome determines the best path forward. Use your primary goal to guide your technique.

- If your primary focus is crystal-clear liquid honey: Rely on the settling method, allowing at least 24 hours in a warm room for the best results.

- If your primary focus is creating clean, usable beeswax: Use the water rendering method to melt, separate, and purify your wax cappings and scraps.

- If you want to maximize both high-quality products: Employ both methods in sequence by first settling your honey and then rendering all the wax you've collected.

Understanding these distinct processes gives you complete control over the quality of your harvest.

Summary Table:

| Method | Goal | Estimated Time | Key Process |

|---|---|---|---|

| Settling | Clarify Honey | 24+ hours | Passive separation by density in a warm tank |

| Rendering | Purify Beeswax | A few hours | Active melting, filtering, and cooling |

Maximize your apiary's efficiency with the right equipment. Whether you're a commercial beekeeper clarifying large honey batches or a distributor needing reliable wax melters, HONESTBEE supplies durable, wholesale-focused beekeeping supplies designed for high-volume operations. Contact our experts today to discuss equipment solutions that save you time and improve product quality.

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Professional Thermostatic Conical Honey Melter

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- What is the mechanism of action for a manual Honey Presser? Maximize Your Yield in Transitional Beekeeping

- In what scenarios is a Honey Presser used? Essential Recovery & Processing Solutions for Modern Apiaries

- How should a new honey press be prepared before its first use? Essential Steps for Pure Honey Production

- What is a honey press and what is it used for? A Guide to Simple Honey Extraction

- How is rope used as an auxiliary consumable in conjunction with muslin cloth during honey pressing?

- What are the main advantages of a honey screw press? Maximize Yield with Compact, Professional Equipment

- What material is used to construct the extruder of a Wax Screw Press? Durable 304 Stainless Steel Solutions

- What improvements does a mechanical jack press offer over manual pressing? Boost Your Honey Yield and Efficiency