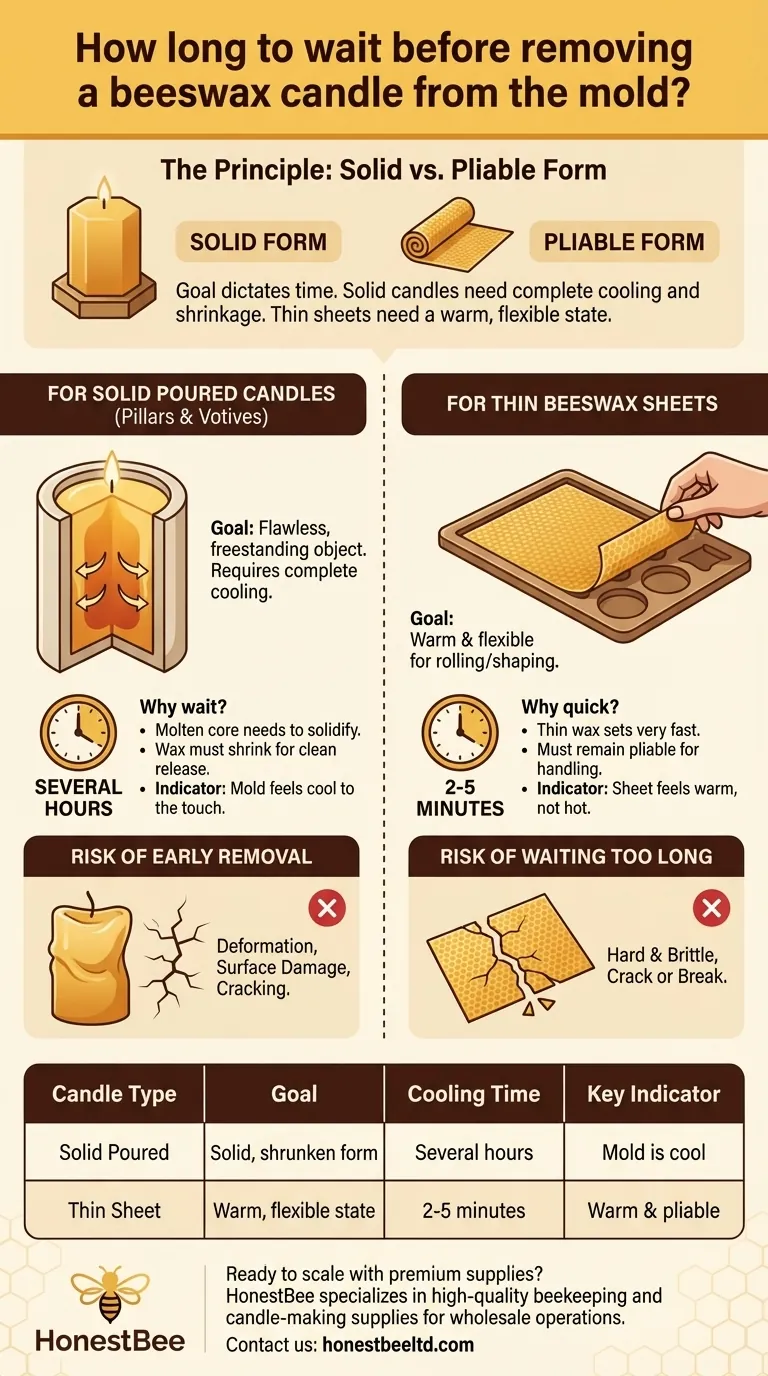

The time you must wait before removing a beeswax candle from its mold depends entirely on the type of candle you are making. For a solid poured candle, such as a pillar or votive, you must wait several hours for it to cool completely. However, for a thin beeswax sheet designed for rolling, you should only wait a few minutes to remove it while it is still warm and pliable.

The core mistake is applying one rule to all candle types. The correct waiting time is determined by your end goal: achieving a perfectly solid, shrunken form for a pillar candle, or preserving a warm, flexible state for a beeswax sheet.

The Principle: Solid vs. Pliable Form

The cooling process serves two fundamentally different purposes depending on the product you are creating. For a solid candle, you need the wax to fully harden and shrink. For a thin sheet, you need it to set just enough to hold its shape while remaining flexible.

Understanding which goal you are aiming for is the most critical step.

For Solid Poured Candles (Pillars & Votives)

When you pour a thick, solid candle, the goal is a flawless, freestanding object. This requires patience and a complete cooling cycle.

Why a Long Cooling Time is Essential

The surface of the wax will lighten in color and "skim over" very quickly, but this is deceptive. The core of the candle remains molten for a significant amount of time.

Removing the candle before this core has fully solidified will cause it to deform, slump, or even collapse.

The Critical Role of Wax Shrinkage

As beeswax cools, it shrinks slightly. This natural shrinkage is what pulls the candle away from the sides of the mold, allowing for a clean and easy release.

If you attempt to demold the candle too early, the wax will not have shrunk sufficiently, causing it to stick to the mold and leading to surface damage.

Key Indicators of Readiness

The most reliable indicator is time. Allow the candle to sit undisturbed in its mold for several hours, or until the entire mold feels cool to the touch at room temperature. A fully cooled candle will have a uniform, light opaque color with no darker, translucent spots.

For Thin Beeswax Sheets

When using a silicone mold to create a thin, patterned beeswax sheet for rolling, the objective is the opposite. You must work quickly.

The Goal: Warm and Flexible Removal

These sheets are meant to be handled, shaped, or rolled into a candle. To do this successfully, the wax must be warm and pliable.

If you allow the sheet to cool completely, it will become brittle and will crack or break as soon as you try to remove it or roll it.

Why a Short Cooling Time Works

Because the sheet is very thin, the wax cools and sets extremely fast. You only need to wait about two to five minutes.

This is just enough time for the wax to solidify so it holds the pattern from the mold, but not so long that it loses its flexibility.

Key Indicators of Readiness

The sheet should feel warm to the touch but not so hot that it loses its shape when handled. One reference notes that seeing air bubbles lift the center of the silicone mold can be a good sign that the sheet is beginning to set and pull away.

Understanding the Risks of Improper Timing

Timing is not a preference; it is a critical process parameter. Getting it wrong will ruin your finished product.

Removing a Solid Candle Too Early

This is the most common mistake for beginners. The consequences include:

- Deformation: The soft, semi-molten core cannot support the candle's weight.

- Surface Damage: The wax will stick to the mold, creating scuffs and gouges.

- Cracking: The temperature difference between the hot core and cool exterior can cause stress fractures.

Waiting Too Long with a Beeswax Sheet

If you let a thin sheet cool completely in its mold, it will become hard and brittle. When you try to peel it from the mold, it will almost certainly crack or snap into pieces, making it useless for rolling.

Making the Right Choice for Your Candle

Your project's goal dictates your process. Use this simple guide to ensure a perfect result every time.

- If your primary focus is creating a solid pillar or votive candle: Wait a minimum of a few hours until the mold is completely cool to the touch to ensure a clean release and perfect shape.

- If your primary focus is making thin beeswax sheets for rolling: Remove the sheet from the mold after only 2-5 minutes, while it is still warm and pliable enough to handle without cracking.

Understanding whether your goal is a rigid form or a flexible sheet is the key to mastering your candle-making process.

Summary Table:

| Candle Type | Goal | Cooling Time | Key Indicator |

|---|---|---|---|

| Solid Poured (Pillar/Votive) | Solid, shrunken form | Several hours | Mold is cool to the touch |

| Thin Beeswax Sheet | Warm, flexible state | 2-5 minutes | Sheet is warm and pliable |

Ready to scale your beekeeping or candle-making business with premium supplies?

As HONESTBEE, we specialize in supplying high-quality beekeeping supplies and equipment directly to commercial apiaries and distributors through our wholesale-focused operations. Whether you need bulk beeswax, reliable molds, or other essential gear, we provide the durable products and expert support to help your business thrive.

Contact our wholesale team today to discuss your needs and discover how we can support your success.

Visual Guide

Related Products

- 3D Square Honeycomb Pillar Silicone Candle Molds for Making Beeswax Candles

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- 3D Beehive Silicone Skep Wax Candle Molds for Candles

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

People Also Ask

- How do you keep beeswax from sticking to a mold? Master the Water Mist Method for a Perfect Release

- What is the step-by-step process for making a beeswax candle? Master the Art of Professional Candle Manufacturing

- What equipment and tools are needed for making beeswax candles? Master the Melt for Safe, Quality Results

- How do specialized processing molds and forming equipment contribute to honey product diversification? Unlock New Revenue

- What value does the production of beeswax candles add to the beekeeping industry? Boost Revenue with Hive Byproducts

- What are the primary performance advantages of 100% pure beeswax candles? High Efficiency & Cleaner Burn

- What components are included in a beekeeping-related candle-making kit? Simplify Your Beeswax Candle Production

- What essential components are required for a beeswax candle-making kit? Professional Tools for High-Quality Production