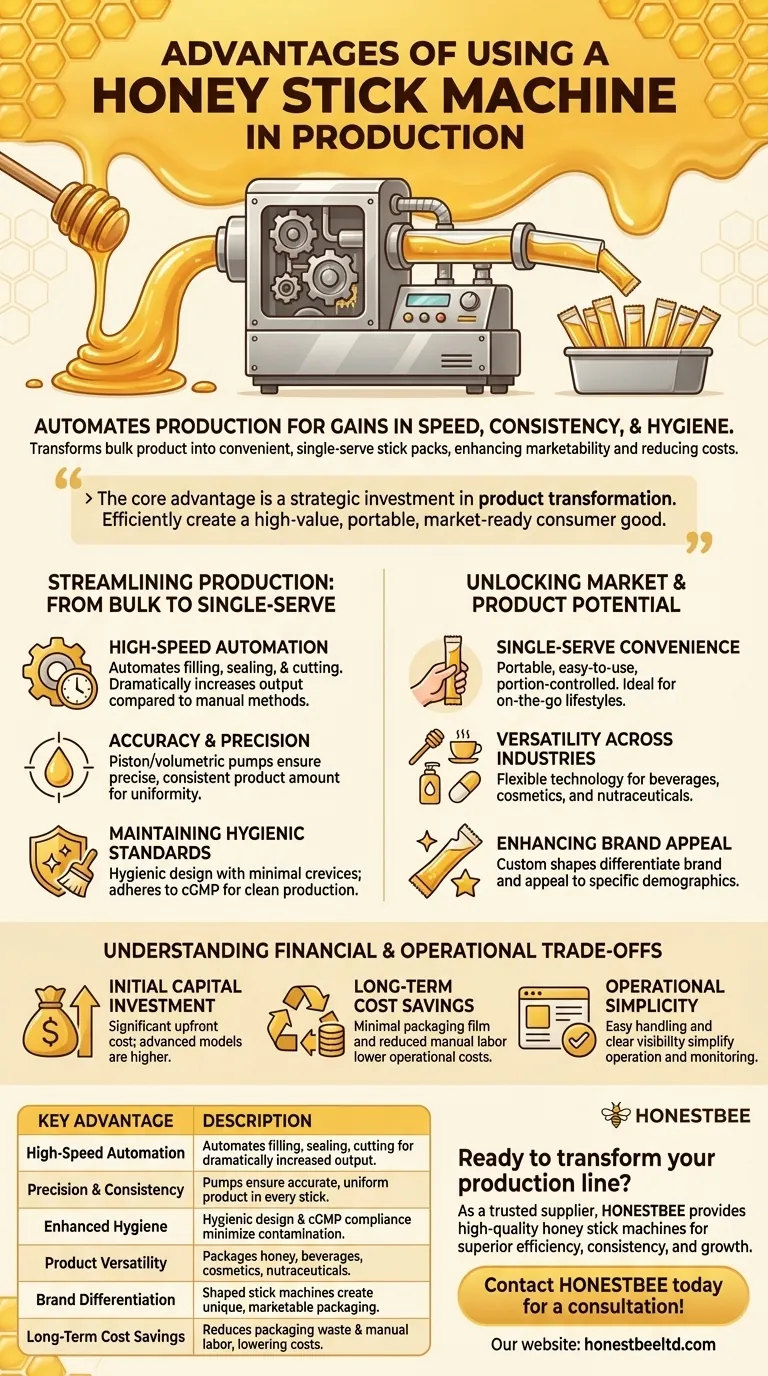

In short, a honey stick machine automates production for significant gains in speed, consistency, and hygiene. It transforms a bulk product like honey into convenient, single-serve stick packs, which enhances marketability and reduces operational costs by minimizing packaging waste and manual labor.

The core advantage of a honey stick machine is not just packaging; it's a strategic investment in product transformation. It allows a producer to efficiently create a high-value, portable, and market-ready consumer good from a raw ingredient.

Streamlining Production: From Bulk to Single-Serve

Investing in a honey stick machine is fundamentally about optimizing your production line. It introduces automation and precision that are difficult to achieve manually.

Achieving High-Speed Automation

The primary operational benefit is speed. These machines automate the filling, sealing, and cutting process, dramatically increasing output compared to any manual or semi-automated method. This allows you to meet changing and growing market demands efficiently.

Ensuring Accuracy and Precision

Equipped with piston and volumetric pumps, honey stick machines deliver a precise, consistent amount of product into every single stick. This accuracy is critical for ensuring product uniformity, managing costs, and meeting consumer expectations for single servings.

Maintaining Hygienic Standards

For any consumable product, hygiene is non-negotiable. These machines are built with a hygienic design that minimizes corners and crevices where contaminants can accumulate. Adherence to standards like cGMP (current Good Manufacturing Practice) ensures a clean production process and reduces the risk of product contamination.

Unlocking Market and Product Potential

Beyond operational efficiency, a honey stick machine opens new avenues for marketing, branding, and product diversification.

The Power of Single-Serve Convenience

The machine's output—the single-serve stick pack—is highly valued by modern consumers. These packs are portable, easy to use, and portion-controlled, making them ideal for on-the-go lifestyles. This convenience is a major selling point.

Versatility Across Industries

While the name implies honey, the technology is highly flexible. The same machine can be used to package a wide range of products, from beverages like coffee and energy drinks to cosmetics like shampoos or makeup removers and nutraceuticals like sports supplements. This versatility allows you to diversify your product offerings with a single equipment investment.

Enhancing Brand Appeal with Custom Shapes

Specialized "shaped" honey stick machines create unique stick packs with styled seals. While a higher initial investment, this offers a powerful way to differentiate your brand on the shelf and appeal to specific demographics, such as children, potentially increasing profits.

Understanding the Financial & Operational Trade-offs

An objective analysis requires looking at both the benefits and the practical considerations of this investment.

The Initial Capital Investment

The primary hurdle is the upfront cost of the machine. This is a significant capital expenditure, and more advanced models with features like custom shaping capabilities will command a higher price.

Long-Term Cost Savings

This initial cost is offset by long-term operational savings. The machine design uses a minimal amount of packaging film per unit, directly reducing material costs. Furthermore, automation reduces the need for manual labor, lowering ongoing wage expenses.

Operational Simplicity

Modern honey stick machines are designed for easy handling and clear visibility. This simplifies operation, reduces the learning curve for staff, and makes monitoring the production process more straightforward.

Making the Right Choice for Your Goal

Ultimately, the decision to invest in a honey stick machine should align with your specific business objectives.

- If your primary focus is maximizing output and efficiency: The machine's high-speed automation and precision filling are its most compelling advantages.

- If your primary focus is entering new consumer markets: The ability to create convenient, portable single-serve products is the key benefit for attracting modern consumers.

- If your primary focus is brand differentiation: A shaped stick machine offers a unique capability to create a visually distinct product that stands out from competitors.

This technology is more than just a piece of packaging equipment; it is a strategic tool for growth, efficiency, and product innovation.

Summary Table:

| Key Advantage | Description |

|---|---|

| High-Speed Automation | Automates filling, sealing, and cutting for dramatically increased output. |

| Precision & Consistency | Piston/volumetric pumps ensure accurate, uniform product in every stick. |

| Enhanced Hygiene | Hygienic design and cGMP compliance minimize contamination risks. |

| Product Versatility | Packages honey, beverages, cosmetics, and nutraceuticals with one machine. |

| Brand Differentiation | Shaped stick machines create unique, marketable packaging. |

| Long-Term Cost Savings | Reduces packaging waste and manual labor, lowering operational costs. |

Ready to transform your production line and unlock new markets?

As a trusted supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the high-quality honey stick machines you need to achieve superior efficiency, product consistency, and brand growth. Let's discuss how our equipment can become a strategic asset for your business.

Contact HONESTBEE today for a consultation and discover the right solution for your goals!

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- How does a piston filling machine function? Master High-Accuracy Viscous Product Filling

- What is the primary value of automated Honey-filling Machines? Scale Your Apiary with Precision and Hygiene

- How do standardized harvesting and bottling equipment affect the economic value of stingless bee honey? Maximize ROI

- What value do industrial honey filling machines provide? Optimize Your Final Stage Production & Market Reach

- How do automated honey filling machines and processing equipment contribute to market competitiveness? From Bulk to Brand

- What is the importance of professional honey processing and honey-filling machinery? Elevate Your Apiary's Value

- What is the significance of automated honey filling machines? Boost Purity and Efficiency in Commercial Processing

- What role do professional Honey-filling Machines play in the honey value chain? Elevate Your Commercial Retail Standard