At its core, a single-lane honey stick machine is a specialized packaging unit defined by its linear, focused design. It produces exactly one honey stick per operational cycle, making it a foundational piece of equipment for many producers due to its compact size and operational simplicity.

The primary characteristic of a single-lane machine is its trade-off: it exchanges the high-volume output of larger systems for a smaller physical footprint, greater product flexibility, and a lower barrier to entry.

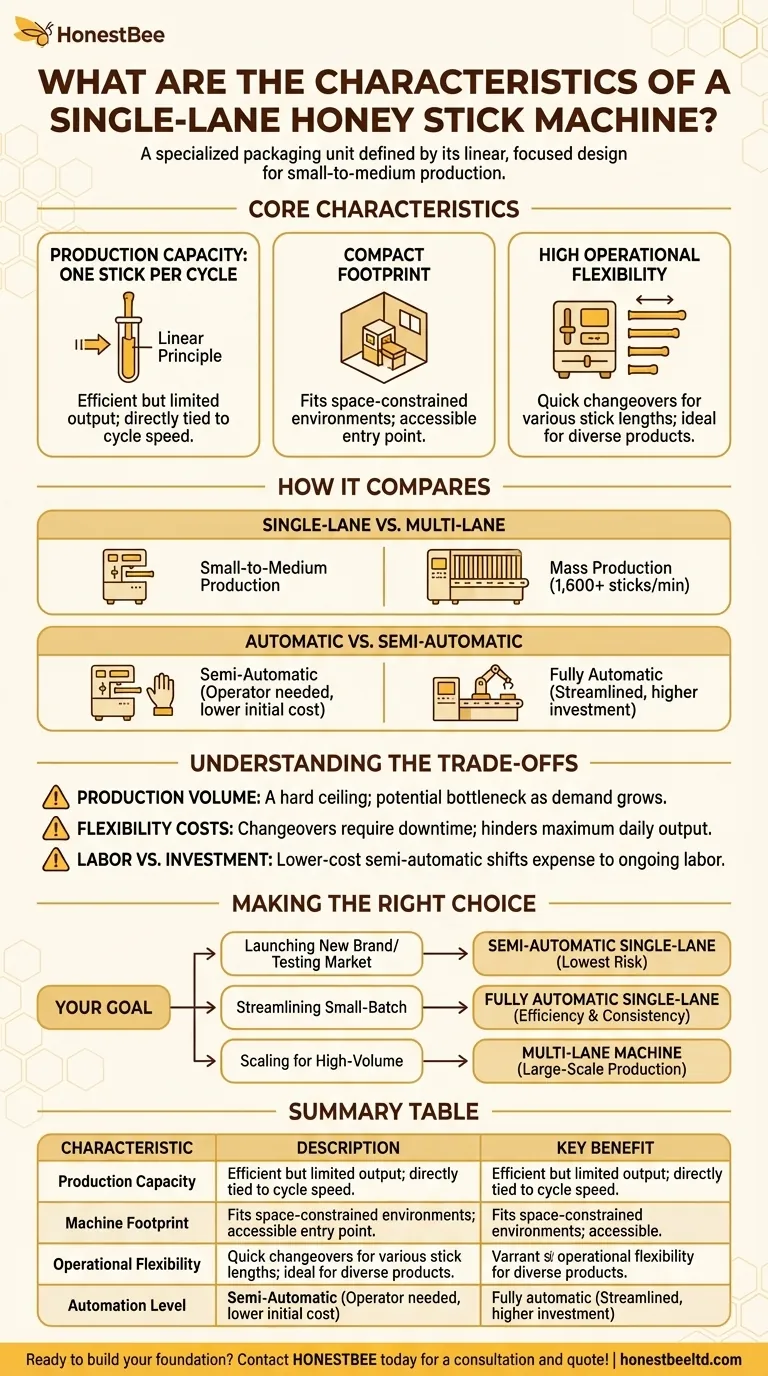

Core Characteristics of a Single-Lane Machine

To understand if this machine is right for you, it's essential to break down its defining features and what they mean for your production process.

Production Capacity: One Stick Per Cycle

A single-lane machine operates on a linear principle. The film is formed into a tube, filled with honey, sealed, and cut—all within a single channel.

This means its output is directly tied to its cycle speed. While efficient, it cannot match the parallel processing of multi-lane systems that produce multiple sticks simultaneously.

Compact Footprint

One of the most significant advantages is its size. These machines are designed to fit into environments with space constraints, such as small workshops, test kitchens, or pilot production facilities.

This makes them an accessible entry point for startups or artisanal producers who do not have the floor space for a large, industrial line.

High Operational Flexibility

Single-lane machines are often engineered for quick changeovers. According to a key reference, parts can be changed rapidly to produce honey sticks of different lengths.

This agility is invaluable for businesses that offer a variety of products or need to run small, customized batches without significant downtime.

How It Compares to Other Models

The value of a single-lane machine becomes clearer when contrasted with the alternatives. The choice depends entirely on your scale and operational goals.

Single-Lane vs. Multi-Lane Machines

The difference here is scale. A single-lane machine is ideal for small-to-medium production.

A multi-lane machine, which can have up to 20 lanes, is built for mass production. These industrial units can produce over 1,600 sticks per minute and are designed for large-scale operations supplying major distributors.

Automatic vs. Semi-Automatic Operation

The term "single-lane" refers to the number of production channels, not the level of automation. A single-lane machine can be either semi-automatic or fully automatic.

A semi-automatic model requires an operator to manually load the film roll or remove the finished sticks. This lowers the initial cost but increases labor requirements.

A fully automatic model handles every step from loading to unloading, streamlining the process for a single operator but typically at a higher initial investment.

Understanding the Trade-offs

No machine is perfect for every scenario. Being objective about the limitations of a single-lane machine is critical for making an informed decision.

Production Volume is a Hard Ceiling

The most obvious trade-off is capacity. A single-lane machine is fundamentally limited by its one-at-a-time output. As your demand grows, it can quickly become a production bottleneck, requiring either shift extensions or the purchase of additional machines.

Flexibility Comes at a Cost

While the ability to change stick lengths is a benefit, each changeover requires downtime. This time, spent adjusting the machine, is time not spent producing. For operations prioritizing maximum daily output of a single product, this flexibility can actually hinder overall throughput.

The Balance of Labor and Investment

Opting for a lower-cost, semi-automatic single-lane machine shifts the expense from capital investment to ongoing labor. You must calculate whether the savings on the machine justify the cost and reliance on manual operator input over the long term.

Making the Right Choice for Your Production Goals

Your decision should be guided by a clear understanding of your business objectives, not just the machine's specifications.

- If your primary focus is launching a new brand or testing market viability: A semi-automatic single-lane machine offers the lowest financial risk and greatest flexibility for product experimentation.

- If your primary focus is streamlining an established small-batch operation: A fully automatic single-lane machine reduces labor costs and improves consistency without demanding a large industrial footprint.

- If your primary focus is scaling for high-volume regional or national distribution: A multi-lane machine is the necessary investment to meet the demands of large-scale production.

By aligning the machine's characteristics with your specific goals, you can confidently select the equipment that will serve as a foundation for your growth.

Summary Table:

| Characteristic | Description | Key Benefit |

|---|---|---|

| Production Capacity | Produces one stick per cycle. | Perfectly suited for small-to-medium batch production. |

| Machine Footprint | Compact, linear design. | Fits easily into workshops or kitchens with limited space. |

| Operational Flexibility | Quick changeovers for different stick lengths. | Ideal for businesses offering a variety of products. |

| Automation Level | Available in semi-automatic and fully automatic models. | Allows you to balance initial investment with labor costs. |

Ready to build the foundation for your honey stick production?

At HONESTBEE, we specialize in supplying beekeeping supplies and equipment to commercial apiaries and distributors. A single-lane honey stick machine is the perfect starting point for a new brand or a reliable workhorse for established small-batch operations.

Our experts can help you select the right model—semi-automatic or fully automatic—to match your production goals and budget. Let us equip you for success.

Contact HONESTBEE today for a personalized consultation and quote!

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- How do automated honey-filling machines improve the honey post-processing stage? Scale Your Apiary Efficiency

- How do automated honey-filling machines assist apiaries in achieving product differentiation for economic feasibility?

- What mechanisms do high-precision honey-filling machines use to maintain honey's biological activity? Preserve Enzymes.

- How do honey filling and processing machines aid native bee product conservation? Boost Value with HONESTBEE Technology

- How do honey-filling machines optimize the value chain? Boost Throughput and Precision for Commercial Distribution

- How do honey filtration and filling machinery contribute to industrialization? Scale Your Commercial Honey Production

- What is the significance of automated honey filling machines? Scale Your Apiary from Wholesale to Premium Retail

- Why is high-precision industrial filling machinery critical for Mad Honey? Ensure Safe Dosage & Premium Quality