The primary types of sealer machines are impulse sealers, continuous band sealers, and vacuum sealers. Each operates on a different principle to accommodate specific packaging volumes, speeds, and product requirements. While most rely on heat to fuse materials, their method of application is what defines their role in an operation.

The key to selecting the right sealer isn't just knowing the types, but understanding the fundamental trade-off you are making between sealing speed, operational volume, and the level of product protection required.

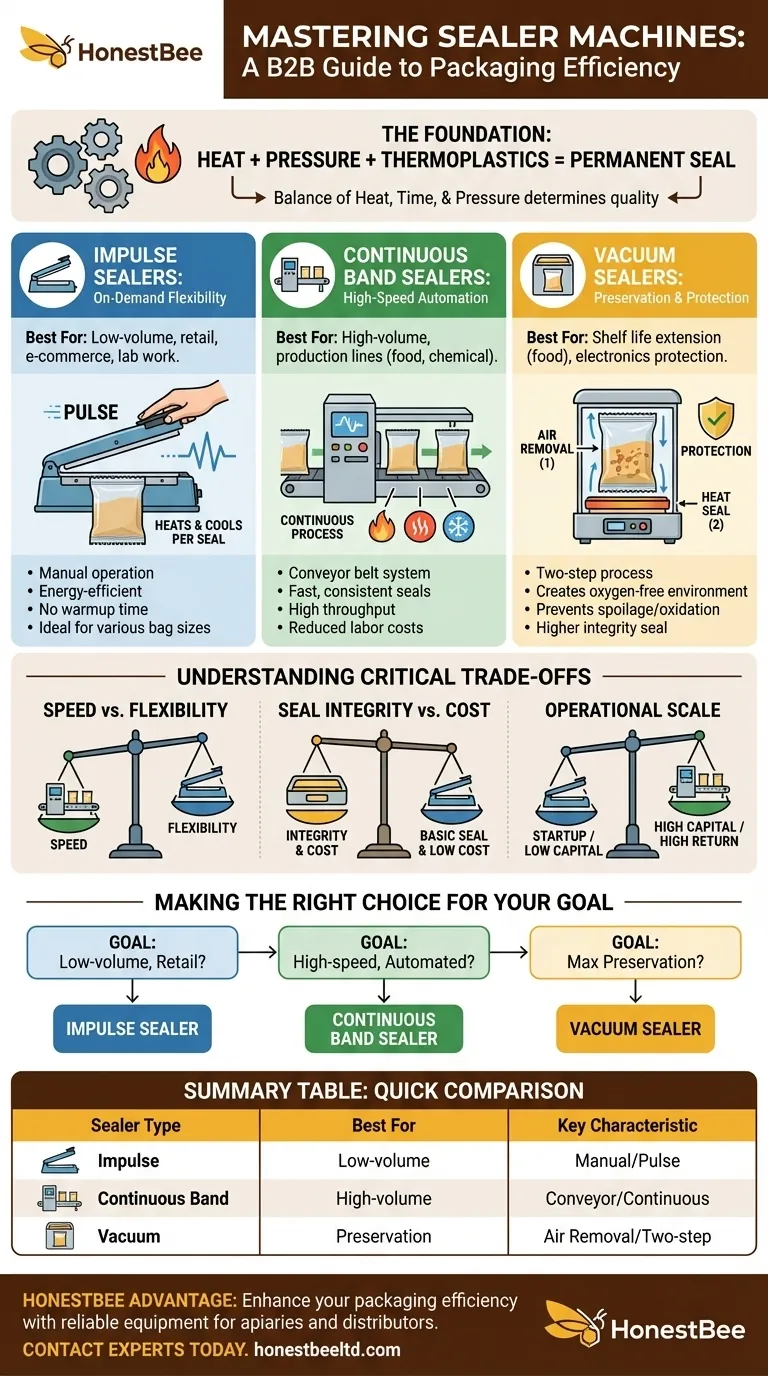

The Foundation: How Heat Sealing Works

All common sealers operate on a simple principle: applying targeted heat and pressure to thermoplastic packaging materials. This process melts the contact surfaces, which then fuse together as they cool, creating a permanent, and often airtight, seal.

The Role of Thermoplastics

The vast majority of flexible packaging, from simple poly bags to complex pouches, is made from thermoplastics. These materials are essential because they can be melted and re-formed without degrading.

Heat, Time, and Pressure

The quality of a seal depends on a precise balance of these three factors. Too much heat can burn the material, while too little will create a weak bond. The machine's job is to apply these elements consistently every time.

A Deep Dive into Sealer Types

Each type of machine is engineered to optimize for a different operational need, from low-volume manual tasks to high-speed automated production lines.

Impulse Sealers: For On-Demand Sealing

An impulse sealer keeps its heating element cool until the sealing jaw is closed onto the material. A quick pulse of electricity heats a wire, makes the seal, and cools down rapidly.

This design is ideal for low-volume applications like retail counters, small e-commerce shipments, or lab work. It is safe, energy-efficient, and easy to use for sealing individual bags as needed.

Continuous Band Sealers: For High-Volume Production

A continuous band sealer is built for speed and automation. Bags are fed into the machine on a conveyor belt, which carries them through a continuous heating and cooling process.

These machines are the workhorses of the food, chemical, and manufacturing industries. They provide fast, consistent, and high-quality seals for production lines that process thousands of packages per hour.

Vacuum Sealers: For Preservation and Protection

A vacuum sealer performs a critical two-step process: first, it removes the air from the package, and second, it creates a heat seal to close it.

This is essential for the food industry to prevent spoilage and extend shelf life. It is also used for sensitive electronics to protect them from moisture and oxidation during shipping and storage.

Understanding the Critical Trade-offs

Choosing a sealer involves balancing speed, cost, and the specific needs of your product. There is no single "best" type; there is only the best fit for your application.

Speed vs. Flexibility

A continuous band sealer offers unmatched speed but is a dedicated, single-purpose machine. An impulse sealer is much slower but offers the flexibility to seal packages of various sizes on demand with no setup time.

Seal Integrity vs. Cost

A basic impulse seal is sufficient for many products. However, a vacuum sealer provides the highest level of protection by creating an oxygen-free environment, which justifies its higher equipment and operational cost for perishable or sensitive goods.

Operational Scale

The initial cost of an impulse sealer is very low, making it perfect for startups. A continuous band sealer represents a significant capital investment intended to deliver a return through high-throughput efficiency and reduced labor costs per package.

Making the Right Choice for Your Goal

Select your machine based on the primary demand of your operation.

- If your primary focus is low-volume or retail packaging: An impulse sealer offers the best balance of low cost, ease of use, and on-demand flexibility.

- If your primary focus is high-speed, automated production: A continuous band sealer is the definitive choice for efficiency and consistent seal quality in a factory setting.

- If your primary focus is maximum product preservation or protection: A vacuum sealer is essential for extending shelf life and safeguarding sensitive contents from the environment.

By aligning the machine’s core function with your operational goals, you can choose a sealer that becomes a reliable asset for your business.

Summary Table:

| Sealer Type | Best For | Key Characteristic |

|---|---|---|

| Impulse Sealer | Low-volume, on-demand sealing | Manual operation; heats and cools for each seal |

| Continuous Band Sealer | High-volume, automated production | Conveyor belt system for fast, consistent sealing |

| Vacuum Sealer | Maximum product preservation | Removes air before sealing to extend shelf life |

Ready to enhance your packaging efficiency?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE understands the critical role reliable equipment plays in your operation. We can help you select the perfect sealer machine to protect your products, improve your workflow, and boost your bottom line.

Contact our experts today to discuss your packaging needs and discover the HONESTBEE advantage.

Visual Guide

Related Products

- Automatic Continuous Heat Sealing Machine

- Handheld Induction Sealing Machine for Tamper Evident Packaging

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- What is the function of an induction sealing machine in packaging? Secure Your Brand with Tamper-Evident Seals

- How should the quality of the seal on a finished honey stick be verified? Ensure Leak-Free Production Success

- How do modern packaging and sealing machines protect black honey? Unlock Global Quality and Premium Brand Value

- What kind of machine is used to seal? Find the Right Sealing Technology for Your Needs

- What is a fin seal on a stick pack? Learn the Key Benefits for Your Packaging Line

- Why is it important to regularly inspect the seal on honey jars? Protect Purity and Extend Shelf Life Successfully

- Why is it necessary to use automatic sealing machines that support multiple specifications for honey packaging?

- What is the role of a sealing mechanism in a packaging machine? Ensure Product Integrity and Long-Term Freshness