An electric double boiler for beeswax is defined by its precise temperature control, automated heating cycle, and intelligent operation. These features are specifically designed to solve the core challenges of melting beeswax: preventing scorching and discoloration, and eliminating fire risk by maintaining a stable, indirect heat source that will not exceed the boiling point of water.

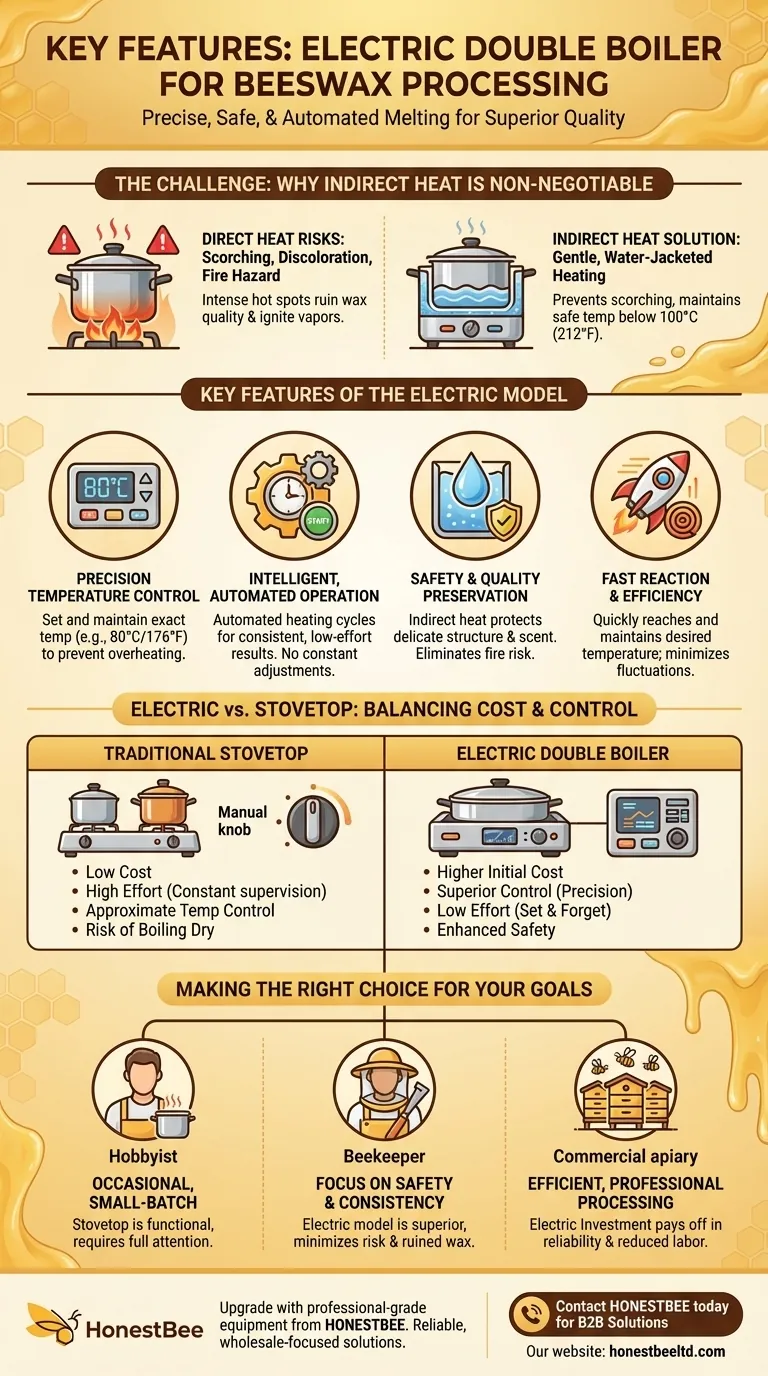

The fundamental challenge in processing beeswax is applying enough heat to melt it without overheating it, which can ruin its quality and create a fire hazard. An electric double boiler's primary advantage is that it automates this delicate balance, combining the safety of indirect heat with the precision of a thermostat for consistent, low-effort results.

Why Indirect Heat is Non-Negotiable for Beeswax

Applying heat directly to a pot of beeswax is risky. A double boiler, whether electric or stovetop, uses a water jacket to create a gentle, indirect heat source that is critical for quality and safety.

Preventing Scorching and Discoloration

Direct heat from a stove or hot plate creates intense hot spots on the bottom of a pot. These spots can easily scorch the beeswax, damaging its natural color and aroma.

To prevent discoloration, beeswax should not be heated above 80°C (176°F). An electric double boiler allows you to set and maintain this precise temperature automatically.

Mitigating Fire Risk

Beeswax is flammable and has a low flashpoint. If overheated, its vapors can ignite.

A double boiler provides an inherent safety mechanism. Because the wax is heated by boiling water, its temperature cannot exceed 100°C (212°F), keeping it well below the danger zone.

Preserving Wax Quality

Slow, controlled melting is the key to preserving the desirable qualities of beeswax. The gentle heat of a double boiler ensures the wax melts uniformly without destroying its delicate structure or pleasant scent.

Key Features of the Electric Model

While a traditional stovetop double boiler provides indirect heat, the electric model adds a layer of precision and automation that transforms the process.

Precision Temperature Control

The standout feature is an integrated thermostat. You can set a specific target temperature, and the unit will automatically cycle its heating element on and off to maintain it.

This removes the guesswork and constant adjustments required with a stovetop, ensuring the wax never overheats.

Intelligent, Automated Operation

An electric unit handles the heating process for you. This "set it and forget it" capability significantly reduces the risk of human error.

You no longer have to worry about the water pot boiling dry, which on a stovetop can cause a sudden, dangerous temperature spike.

Fast Reaction and Efficiency

Modern electric double boilers are designed for fast and efficient heating. They quickly bring the water jacket to the desired temperature and react promptly to maintain it, preventing wide temperature swings.

Understanding the Trade-offs: Electric vs. Stovetop

Choosing between an electric and a traditional stovetop double boiler comes down to balancing cost against control and convenience.

The Stovetop Method: Low Cost, High Effort

Using two pots on a stove is inexpensive. However, it demands constant supervision. You must manually regulate the heat and ensure the water level never gets too low. Temperature control is, at best, an approximation.

The Electric Method: Higher Cost, Superior Control

An electric double boiler is a specialized piece of equipment and represents a greater initial investment.

The return on this investment is unparalleled safety, consistency, and significantly reduced labor. It is the professional's choice for achieving repeatable, high-quality results.

Making the Right Choice for Your Goal

Your ideal method depends on your specific needs, batch size, and commitment to the craft.

- If your primary focus is occasional, small-batch melting: A traditional stovetop double boiler is a perfectly functional starting point, provided you can give it your full attention during use.

- If your primary focus is safety and consistency: An electric double boiler is the superior choice, as its automated temperature control minimizes the risk of ruined wax or accidents.

- If your primary focus is processing wax efficiently or professionally: The investment in an electric model quickly pays for itself through reliable outcomes, reduced active labor, and enhanced safety.

Ultimately, an electric double boiler elevates beeswax processing from a manual chore into a controlled, repeatable science.

Summary Table:

| Feature | Benefit for Beekeepers |

|---|---|

| Precision Temperature Control | Prevents scorching & discoloration; preserves wax quality. |

| Automated Heating Cycle | Reduces labor & human error; ensures consistent results. |

| Indirect Heat (Water Jacket) | Eliminates fire risk by keeping wax below 100°C (212°F). |

| Intelligent Operation | "Set and forget" functionality for efficient, worry-free processing. |

Upgrade your beeswax processing with professional-grade equipment from HONESTBEE.

We supply commercial apiaries and beekeeping equipment distributors with reliable, wholesale-focused solutions. An electric double boiler from HONESTBEE delivers the precision and safety you need to protect your product quality and streamline your operation.

Contact HONESTBEE today to discuss your equipment needs and discover how our wholesale solutions can benefit your business.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards