The primary advantages of a frame wax melter are its significant boost in efficiency and its simple design. By allowing you to load honeycombs directly into the unit without cutting them out of the frames, these melters streamline the entire wax rendering process, saving considerable time and labor.

The term "frame wax melter" describes how the material is loaded, but the most important decision is the heat source. Your choice between solar, steam, or electric power will define your workflow, processing speed, and safety considerations.

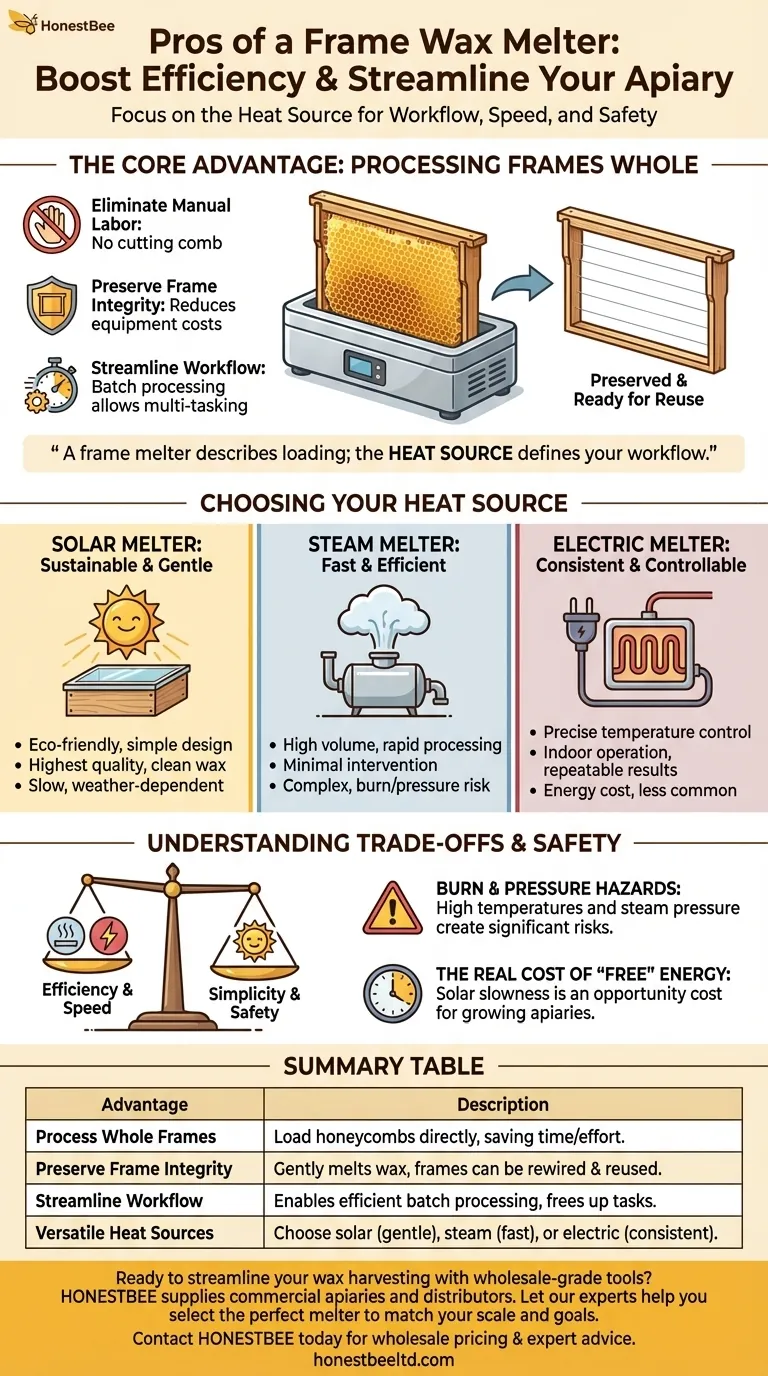

The Core Advantage: Processing Frames Whole

The single greatest benefit of any frame wax melter is its ability to handle intact frames. This core function creates several downstream advantages for the beekeeper.

Eliminating Manual Labor

The most tedious part of rendering old comb is cutting it out of the frame wire by wire. A frame melter completely eliminates this step.

You simply place the entire frames inside the unit, saving hours of sticky, repetitive work. This dramatically improves the efficiency of your operation.

Preserving Frame Integrity

By melting the wax off gently, the wooden frames themselves are often left clean and intact. After a quick scraping, they can be rewired and fitted with a new foundation, ready to go back into the hive.

This ability to reuse frames reduces equipment costs and waste over the long term.

Streamlining the Workflow

Frame melters are designed for batch processing. You can load a set number of frames, start the melting process, and attend to other tasks in the apiary. This creates a much more manageable and predictable workflow compared to piece-by-piece methods.

Choosing Your Heat Source: Solar vs. Steam vs. Electric

The "pro" you care about most will depend entirely on the type of frame melter you choose. The heat source is the defining factor.

The Solar Melter: Sustainable and Gentle

A solar wax melter uses the sun's energy, captured under glass, to slowly melt the wax. It is the most environmentally friendly and simple option.

This slow, controlled melting process results in very high-quality, clean wax that is less likely to be darkened or scorched. Because it requires no external power, it can be used anywhere there is sunlight.

The Steam Melter: Fast and Efficient

A steam wax melter uses an external steam generator to inject hot steam, rapidly melting the comb. This is the workhorse for beekeepers who need to process a high volume of frames quickly.

The process is fast, and the design requires minimal intervention from the beekeeper once it's running. This is the choice for maximizing throughput.

The Electric Melter: Consistent and Controllable

An electric wax melter uses a heating element to maintain a consistent temperature. This offers a high degree of control and the ability to operate indoors, independent of weather.

While not as common as solar or steam variants, electric models provide predictable performance for professionals who need repeatable results.

Understanding the Trade-offs and Safety Risks

No single solution is perfect. Choosing a melter requires understanding the direct trade-offs between speed, cost, and safety.

Efficiency vs. Simplicity

Solar melters are the simplest and safest but are also the least efficient. Their output is entirely dependent on sunny weather and can be slow.

Steam melters offer maximum speed and efficiency but introduce more complexity and potential safety hazards.

Burn and Pressure Hazards

Any system using high temperatures presents a burn risk. Steam melters add another layer of risk: steam pressure. If a hose or connection fails under pressure, it can cause severe burns.

The Real Cost of "Free" Energy

While a solar melter uses free energy from the sun, its slowness represents an opportunity cost. The time it takes to process a batch of frames could be a limiting factor for a growing apiary. Steam and electric models have an energy cost but buy you significant time.

Making the Right Choice for Your Apiary

Select your equipment based on the scale of your operation and your primary goals.

- If your primary focus is sustainability and wax quality for a small apiary: A solar wax melter is the ideal, low-maintenance choice.

- If your primary focus is speed and processing a large volume of frames: A steam wax melter is the most effective tool for the job.

- If your primary focus is precise temperature control and indoor operation: An electric wax melter offers unmatched consistency.

Choosing the right frame wax melter is about aligning the tool with the philosophy and scale of your beekeeping practice.

Summary Table:

| Advantage | Description |

|---|---|

| Process Whole Frames | Load honeycombs directly without cutting, saving significant time and effort. |

| Preserve Frame Integrity | Gently melts wax, allowing frames to be cleaned, rewired, and reused. |

| Streamline Workflow | Enables efficient batch processing, freeing you up for other tasks. |

| Versatile Heat Sources | Choose from solar (gentle/sustainable), steam (fast/efficient), or electric (consistent/controllable) models. |

Ready to streamline your wax harvesting and boost your apiary's efficiency?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the robust, wholesale-grade tools they need to succeed. A high-quality frame wax melter is an investment in the productivity and longevity of your operation.

Let our experts help you select the perfect melter—solar, steam, or electric—to match your scale and goals.

Contact HONESTBEE today for wholesale pricing and expert advice on the right equipment for your business.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Steam Beeswax Melter Wax Warmer for Wax Processing

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What is the best way to melt beeswax for candles? The Safest Method for Professional Results

- How do water jacket melters function? Achieve Gentle, Scorch-Free Melting for Sensitive Materials

- What role do precision wax melting units and molds play? Professional Beeswax Processing & Crafting Guide

- What are the main types of wax melters? Choose the Right Heating Method for Your Needs