In short, a honey settling tank is a container used to clarify raw honey after it has been extracted from the comb. It works by allowing impurities like wax fragments, air bubbles, and other hive debris to naturally separate from the honey over time through the simple force of gravity. This is a critical step for producing clean, clear, and professional-quality honey.

The primary purpose of a honey settling tank is not to store honey, but to act as a purification chamber. It leverages gravity to separate the pure, liquid honey from the lighter-than-honey debris that rises to the top and the heavier debris that sinks to the bottom.

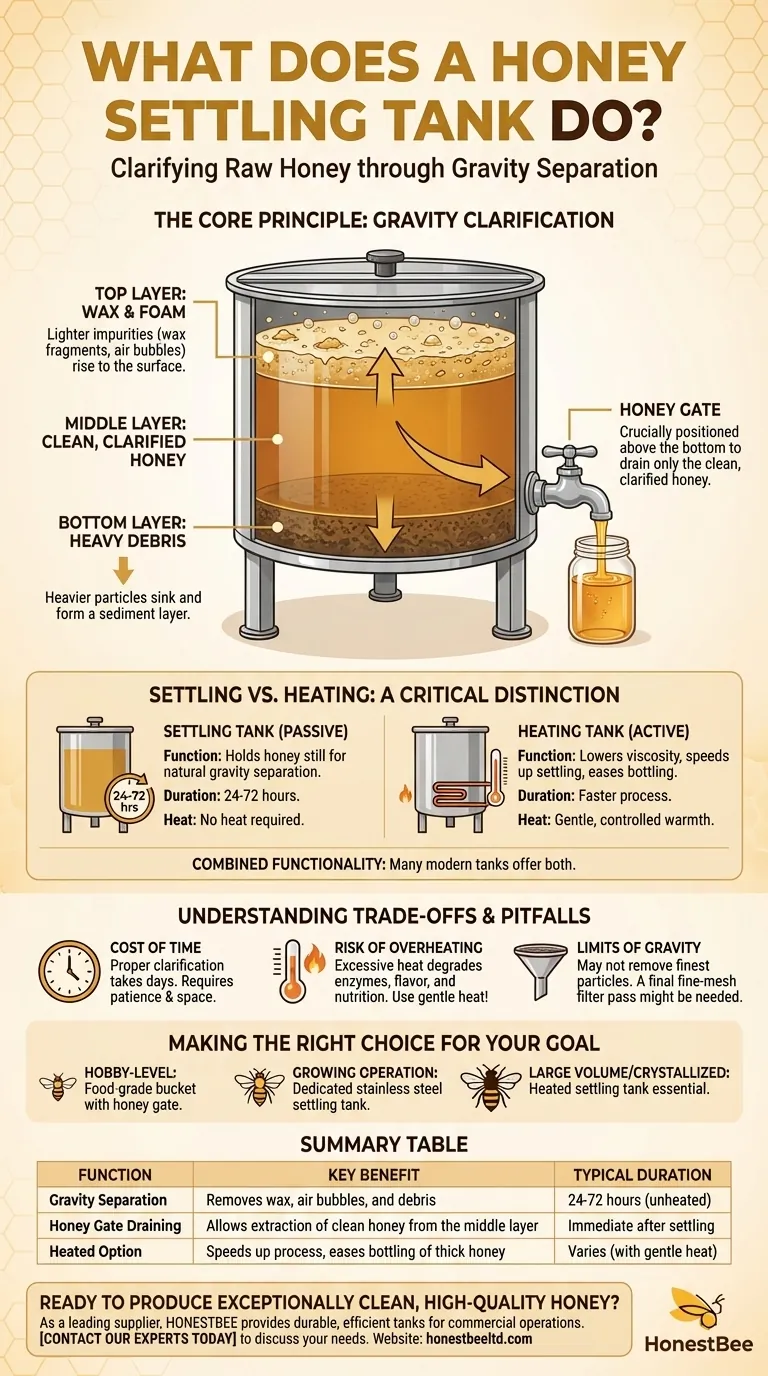

The Core Principle: How Gravity Clarifies Honey

After honey is spun out of the comb in an extractor, it contains a mix of air bubbles, tiny wax particles, and other bits of hive debris. A settling tank provides a still environment where these elements can separate based on their density.

Eliminating Wax and Foam

Wax is less dense than honey. When honey is left to sit undisturbed in a settling tank, these small wax particles, along with any foam created during extraction, will slowly float to the surface. This forms a distinct layer at the top.

Removing Heavy Debris

While most hive debris is lighter than honey, any heavier particles will sink to the bottom of the tank, forming a sediment layer. This further cleans the main body of the honey.

The Role of the Honey Gate

Settling tanks are equipped with a "honey gate" or tap. Crucially, this gate is positioned several inches above the bottom of the tank. This allows you to drain the clean, clarified honey from the middle, leaving both the top layer of wax and the bottom layer of sediment behind.

Settling vs. Heating: A Critical Distinction

While sometimes combined, settling tanks and heating tanks serve different primary functions in honey processing. Understanding this difference is key to maintaining honey quality.

The Function of a Settling Tank

A standard settling tank is a passive tool. Its job is simply to hold the honey still for a period of 24-72 hours to allow for natural, gravity-based separation. No heat is required for this process.

The Function of a Heating Tank

A honey heating tank applies gentle, controlled warmth. The goal is to lower the honey's viscosity (make it more fluid), which makes it easier to strain and bottle. This process also significantly speeds up the settling process, as bubbles and wax can rise much faster through thinner honey.

Combined Functionality

Many modern tanks offer both functions. They are built as settling tanks but also include a heating element. This provides the beekeeper with the flexibility to gently warm the honey to accelerate clarification and ease bottling, especially with honey that crystallizes quickly.

Understanding the Trade-offs and Pitfalls

Using a settling tank is a fundamental part of honey processing, but it's important to be aware of the associated considerations.

The Cost of Time

The most significant trade-off of unheated settling is time. Proper clarification can take several days, which requires patience and space in your processing area.

The Risk of Overheating

If using a heated tank, the primary risk is degrading the honey. Excessive heat destroys the natural enzymes and beneficial compounds in honey, altering its flavor and nutritional value. The key is gentle and controlled heating, never letting the honey get too hot.

The Limits of Gravity

Settling is excellent for removing most visible impurities. However, it may not remove the absolute finest particles. For perfectly clear, competition-grade honey, a final pass through a fine-mesh filter after settling is often required.

Making the Right Choice for Your Goal

The right equipment depends entirely on the scale of your operation and your quality standards.

- If your primary focus is hobby-level beekeeping: A simple food-grade bucket fitted with a honey gate can function perfectly well as a basic settling tank.

- If your primary focus is efficiency for a growing operation: A dedicated stainless steel settling tank is a crucial investment that dramatically improves your workflow and final product quality.

- If your primary focus is processing large volumes or crystallized honey: A heated settling tank becomes essential for managing viscosity and ensuring a smooth, efficient process from extractor to bottle.

Ultimately, integrating a settling tank into your workflow is a foundational step toward producing exceptionally clean and high-quality honey.

Summary Table:

| Function | Key Benefit | Typical Duration |

|---|---|---|

| Gravity Separation | Removes wax, air bubbles, and debris | 24-72 hours (unheated) |

| Honey Gate Draining | Allows extraction of clean honey from the middle layer | Immediate after settling |

| Heated Option | Speeps up process, eases bottling of thick honey | Varies (with gentle heat) |

Ready to produce exceptionally clean, high-quality honey?

As a leading supplier to commercial apiaries and distributors, HONESTBEE provides the durable, efficient honey settling tanks and processing equipment you need to scale your operation. Our wholesale-focused solutions are designed for professional beekeepers who demand reliability and superior results.

Contact our experts today to discuss your specific needs and discover how our equipment can enhance your honey's clarity and your operation's efficiency.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Stainless Steel Honey Filter with Support Handle

- Professional Honey Storage Tank with Agitation System

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

People Also Ask

- What are the functions and advantages of using honey strainers? Ensure Purity & Quality in Your Harvest

- Why is filtering honey an important step in honey processing? Ensure Purity, Clarity & Marketability

- What is the primary purpose of honey filters? Achieve Professional Clarity & Pure Honey Quality

- How does automated honey filtration and filling machinery improve quality? Guard Your Apiary Against Pest Contamination

- Why is filtering honey considered an essential step in honey processing? Ensure Quality and Commercial Viability