The decision between an electric and a manual honey extractor hinges on four key factors: the number of hives you manage, the value of your time and physical effort, your budget, and your long-term beekeeping goals. For a small number of hives, a manual extractor is a cost-effective choice. However, as your apiary grows, an electric model quickly becomes a necessary investment in efficiency.

While cost is an immediate concern, the right choice is fundamentally about aligning your equipment with the scale of your operation. A manual extractor is a sensible start for a hobbyist, but it can quickly become a bottleneck to growth. An electric extractor is a significant upfront investment that pays dividends in time and labor savings for any serious beekeeper.

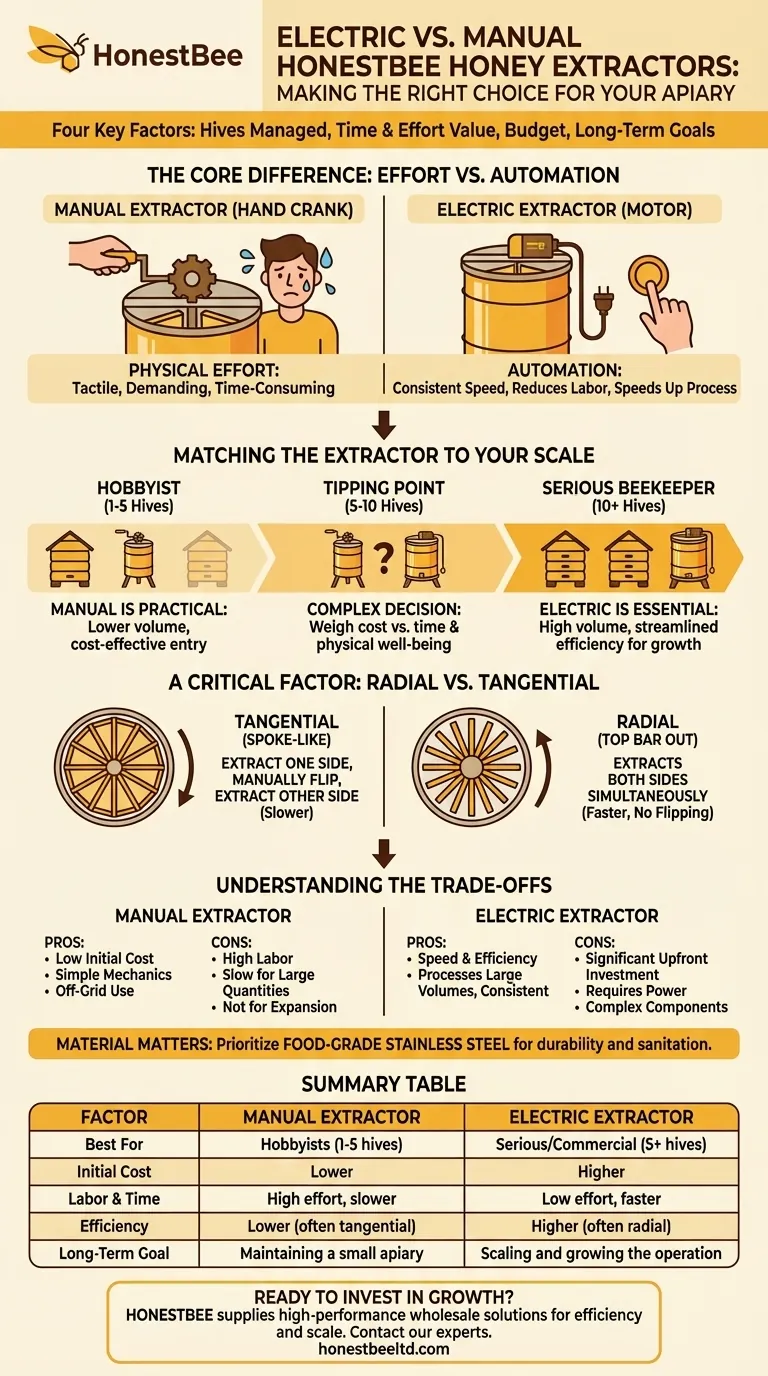

The Core Difference: Effort vs. Automation

The fundamental choice between manual and electric comes down to the power source. This single difference has significant ripple effects on your entire honey harvesting process.

How a Manual Extractor Works

A manual extractor uses a hand crank to spin a central basket holding the honey frames. The operator's physical effort generates the centrifugal force needed to pull the honey from the comb.

This process gives you a tactile, hands-on connection to the harvest. You can finely control the speed, which is useful for delicate new comb, but it is physically demanding and time-consuming.

How an Electric Extractor Works

An electric extractor replaces the hand crank with an electric motor. With the press of a button or the turn of a dial, the motor spins the basket at a consistent, pre-set speed.

This automation dramatically reduces physical labor and speeds up the entire extraction process, allowing you to process more honey in far less time.

Matching the Extractor to Your Scale

The number of hives you manage is the single most important factor in this decision. Your goal is to choose a tool that matches your workload.

The Hobbyist Scale (1-5 Hives)

For a beekeeper with a handful of hives, a manual extractor is the most practical choice. The lower volume of honey makes the time and labor investment manageable.

The significant cost savings compared to an electric model make it the clear winner at this scale.

The Tipping Point (5-10 Hives)

This range is the gray area where the decision becomes more complex. Extracting honey from over five hives with a manual crank can become an exhausting, multi-hour task.

At this point, you must seriously weigh the cost of an electric model against the value of your time and physical well-being. Many beekeepers who plan to expand choose to invest in an electric model here.

The Serious Beekeeper (10+ Hives)

For anyone managing ten or more colonies, an electric extractor is no longer a luxury; it is essential equipment. The sheer volume of frames makes manual extraction impractical.

An electric model transforms harvesting from an arduous chore into a streamlined and efficient process, freeing you to focus on other aspects of your apiary.

A Critical Factor Beyond Power: Radial vs. Tangential

The way an extractor holds the frames—either tangential or radial—has a massive impact on efficiency, regardless of the power source.

Tangential Extractors

Tangential extractors position the frames like the spokes of a wheel, with one side of the comb facing outward. This design requires you to extract one side, manually flip the frames, and then extract the other side.

This method is common in smaller, less expensive manual extractors. The need to flip every frame significantly adds to the total processing time.

Radial Extractors

Radial extractors position the frames with the top bar facing outwards. Centrifugal force pulls honey from both sides of the comb simultaneously.

This design, most common in electric models, is vastly more efficient. It completely eliminates the time-consuming step of flipping frames, effectively cutting your extraction time in half.

Understanding the Trade-offs

No choice is without its compromises. Objectively weighing the pros and cons is key to avoiding buyer's remorse.

The Manual Extractor: Low Cost, High Labor

The primary advantage is low initial cost. These units are also simpler mechanically, lighter, and can be used in off-grid locations without electricity.

The clear disadvantage is the high labor requirement. It is physically demanding and very slow for large quantities, making it a poor choice for expansion.

The Electric Extractor: High Efficiency, Higher Cost

The obvious benefit is speed and efficiency. Electric models drastically reduce physical effort and process large volumes of honey quickly and consistently.

The main drawback is the significant upfront investment. They also require a power source and have more complex components that could potentially fail.

Material Matters: Stainless Steel is the Standard

Regardless of your choice, prioritize models made from food-grade stainless steel. It is durable, will not rust, and is easy to clean and sanitize. Avoid cheaper plastic or coated-steel models, which can degrade or flake over time.

Making the Right Choice for Your Apiary

Select your extractor based on a realistic assessment of your current needs and future ambitions as a beekeeper.

- If your primary focus is keeping a few backyard hives: A small, manual tangential extractor offers the best balance of affordability and function.

- If your primary focus is growing your apiary beyond 5-10 hives: An electric radial extractor is a necessary investment that will save you significant time and labor.

- If your primary focus is maximum efficiency for a commercial or large side-line operation: A large-capacity electric radial extractor is the professional standard.

Ultimately, view your extractor not as an expense, but as a long-term investment in the efficiency and enjoyment of your beekeeping practice.

Summary Table:

| Factor | Manual Extractor | Electric Extractor |

|---|---|---|

| Best For | Hobbyists (1-5 hives) | Serious/Commercial Beekeepers (5+ hives) |

| Initial Cost | Lower | Higher |

| Labor & Time | High effort, slower | Low effort, faster |

| Efficiency | Lower (often tangential) | Higher (often radial) |

| Long-Term Goal | Maintaining a small apiary | Scaling and growing the operation |

Ready to invest in the right extractor for your apiary's growth?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with durable, high-performance honey extractors built for efficiency and scale. Whether you're upgrading to your first electric model or need a reliable radial extractor for a large operation, our wholesale-focused solutions are designed to save you time and labor.

Contact our experts today to discuss your specific needs and discover how our equipment can enhance your honey harvesting process.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What are the advantages of automated honey extractors in terms of time efficiency? Boost Your Harvest Speed

- Why is preserving honeycomb integrity important, and how do automated extractors help? Boost Hive Health & Honey Yields

- What are the two common types of honey extractors? Choose the Right Extractor for Your Apiary

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- What are the advantages of electric honey extractors? Boost Efficiency for Your Commercial Apiary