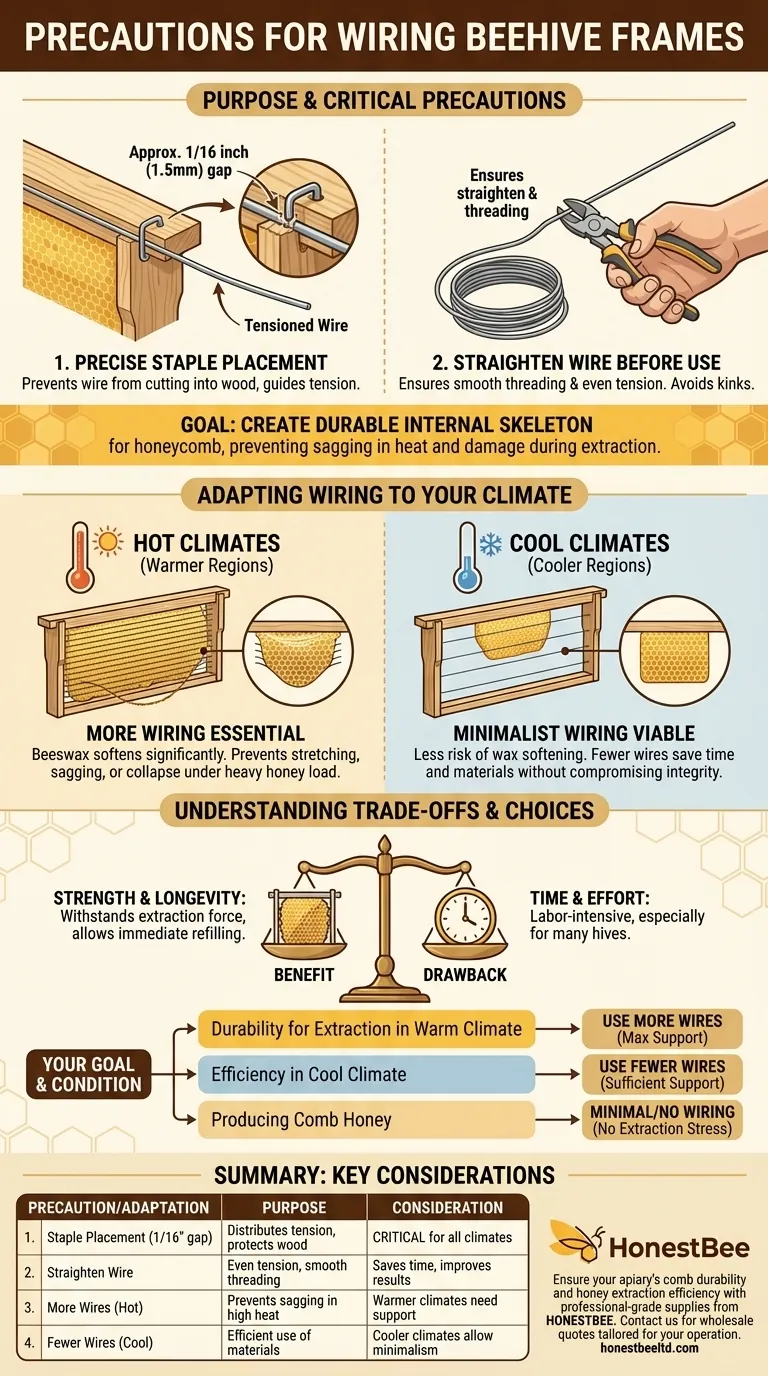

The most critical precautions when wiring beehive frames involve precise staple placement and preparing the wire correctly. You must position staples approximately 1/16 inch from the wire holes to prevent the tensioned wire from cutting into the wood, and straighten the wire beforehand to ensure it threads smoothly and tightens evenly.

The goal of wiring is not merely to hold the foundation in place, but to create a durable internal skeleton for the honeycomb. This structure is essential for preventing comb sagging in high heat and withstanding the intense forces of a honey extractor.

The Purpose of Proper Wiring

Wiring provides the crucial structural support that a sheet of wax foundation needs to become a strong, functional honeycomb. Without this reinforcement, the comb is vulnerable to collapse under its own weight, especially when filled with heavy honey and exposed to hive temperatures.

Preventing Damage to the Frame

The most common mistake is allowing the wire to compromise the wooden frame itself. When wire is tensioned, it exerts significant pressure on the wood it touches.

Proper staple placement acts as a guide, ensuring the wire's tension is distributed correctly. Placing the staple 1/16 inch from the wire hole keeps the wire from digging into the softer wood of the side bar, which would weaken the frame over time.

Ensuring a Straight and Taut Foundation

The wire must be prepared before you begin threading it through the frame's eyelets or holes. A kinked or bent wire is difficult to thread and impossible to tension evenly.

Use a wire cutter or shears to straighten the length of wire before you start. This simple step saves considerable frustration and results in a more uniform, taut support system for the wax foundation.

Adapting Wiring to Your Climate

The amount of wiring a frame requires is not universal; it is dictated by your local climate. Heat is the primary variable that determines how much support a honeycomb needs.

High-Heat Environments

In warmer regions, the beeswax within the hive can soften significantly. This makes the heavy, honey-filled comb prone to stretching, sagging, or even collapsing entirely.

For this reason, more wiring is essential in hot climates. A minimalist approach is impractical and risky, as it fails to provide the necessary support to counteract the effects of heat.

Cooler Environments

In cooler climates, particularly in the northern hemisphere, hive temperatures rarely reach levels that cause significant wax softening. The risk of comb sagging is much lower.

In these conditions, minimalist wiring is a viable option. Beekeepers can often use fewer horizontal strands of wire, saving both time and materials without compromising the structural integrity of the comb.

Understanding the Trade-offs

Deciding on a wiring strategy involves balancing durability against the time and effort required for preparation.

The Benefit of Wiring: Strength and Longevity

The primary advantage of wiring is strength. A properly wired frame can withstand the immense centrifugal force of a honey extractor, allowing for efficient honey harvesting without destroying the comb. This allows the bees to refill the comb immediately, saving them significant energy.

The Drawback of Wiring: Time and Effort

The main disadvantage is the labor involved. Wiring frames is a time-consuming and sometimes tedious task, especially for beekeepers managing a large number of hives.

When Minimal Wiring Makes Sense

Minimal wiring is best suited for cooler climates or for frames that will not be put through a mechanical extractor. For example, frames used for producing cut-comb honey do not require the same level of reinforcement.

Making the Right Choice for Your Goal

Your wiring strategy should directly support your beekeeping objectives and environmental conditions.

- If your primary focus is durability for honey extraction in a warm climate: Use more horizontal wires to provide maximum support against both heat and the force of the extractor.

- If your primary focus is efficiency in a cool climate: You can safely use fewer wires, as the risk of heat-related comb sagging is minimal.

- If your primary focus is producing comb honey: Minimal or no wiring is often sufficient, as these frames are not subjected to the stress of extraction.

Properly wiring your frames is a foundational investment in the long-term health and productivity of your hive.

Summary Table:

| Key Precaution | Purpose | Key Consideration |

|---|---|---|

| Staple Placement (1/16" from hole) | Distributes wire tension, prevents wood damage | Critical for all climates |

| Straighten Wire Before Threading | Ensures even tension, smooth threading | Saves time, improves results |

| Climate-Adapted Wiring (More wires for heat) | Prevents comb sagging in high temperatures | Warmer climates require more support |

| Climate-Adapted Wiring (Fewer wires for cool) | Efficient use of materials where risk is low | Cooler climates can use minimalist approach |

Ensure your apiary's comb durability and honey extraction efficiency with professional-grade supplies from HONESTBEE.

We supply commercial apiaries and distributors with the high-quality wiring tools, frames, and equipment needed for precise, long-lasting results. Our wholesale-focused operations are designed to support your scale and success.

Contact HONESTBEE today to discuss your beekeeping supply needs and get a quote tailored for your operation.

Visual Guide

Related Products

- HONESTBEE Professional Frame Wiring Board and Jig

- HONESTBEE 15-in-1 Beekeeper Multi-Tool with Hammer and Pliers for Beekeeping

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- Professional Pneumatic Wire Embedder for Beehive Frames

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- Why is a standardized hive and frame structure necessary for long-term honeybee vibration monitoring? Ensure Data Integrity

- What steps are necessary to prevent cross comb in foundationless beekeeping? A Guide to Perfect Comb

- What is the purpose of using fully drawn honeycomb frames in pesticide monitoring? Ensure Data Accuracy and Isolation

- What is foundationless beekeeping and why might a beekeeper choose it? A Guide to Natural Comb

- How must plastic frames be prepared for bees? Expert Tips for 100% Acceptance & Success

- How much honey can be extracted from one frame? Maximize Your Harvest with the Right Frame Size

- What is the impact of movable-frame beehives on beeswax yield? Maximize Honey Production with Smart Hive Systems

- How is a standard frame grid used to evaluate the development and strength of a honeybee colony? Master Hive Precision