At its core, a Beehive Frame Making Machine is a specialized piece of equipment designed to perform all the necessary cuts and bores to manufacture the four wooden components of a standard beehive frame. It consolidates multiple woodworking processes into a single unit, capable of milling tenons, cutting grooves, and drilling holes for the top bar, sidebars, and bottom bar.

This machine is not just a tool, but a complete production system. Its value lies in streamlining the entire frame-building process, replacing multiple general-purpose tools with one specialized, efficient, and consistent solution for beekeepers and suppliers.

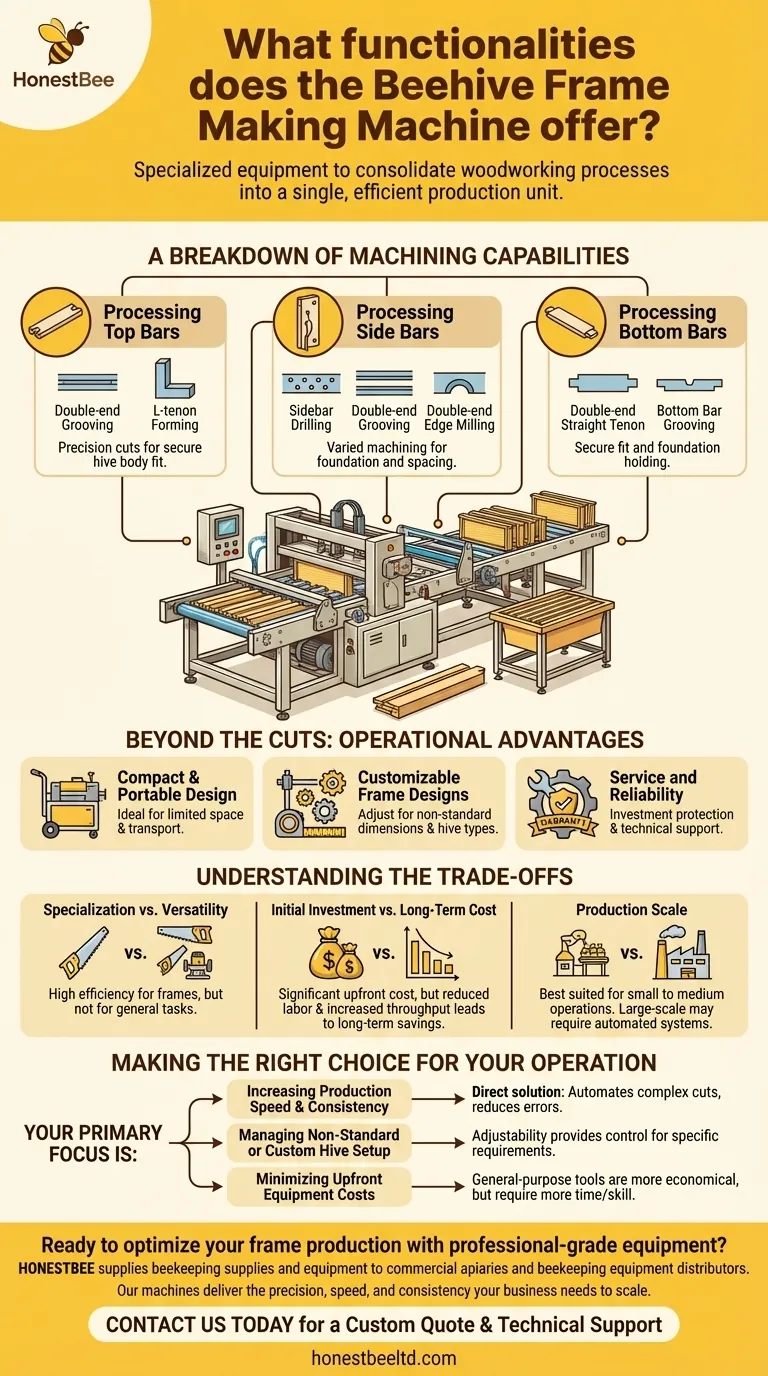

A Breakdown of Machining Capabilities

The machine is engineered to precisely shape each part of the beehive frame, ensuring they fit together perfectly. The functions are best understood by the specific component they process.

Processing Top Bars

The top bar requires specific cuts to rest securely in the hive body and hold the foundation. The machine handles double-end grooving and L-tenon forming, creating the precise joints needed for a strong and stable frame structure.

Processing Side Bars

Sidebars are the vertical components that require the most varied machining. The machine performs sidebar drilling for wiring the foundation, double-end grooving to accept the top and bottom bars, and double-end edge milling to create the correct spacing between frames inside the hive.

Processing Bottom Bars

The bottom bar completes the frame. The machine creates a double-end straight tenon on the bottom bar, which fits securely into the grooves on the sidebars. It can also perform bottom bar grooving to help hold the wax or plastic foundation in place.

Beyond the Cuts: Operational Advantages

Beyond its specific cutting functions, the machine offers features that address the practical needs of a modern beekeeping operation.

Compact & Portable Design

Many of these machines are designed to be compact and relatively portable. This is a significant advantage for beekeepers with limited workshop space or for those who may need to transport the equipment.

Customizable Frame Designs

The ability to adjust the machine allows for customizable designs. This enables a beekeeper to produce frames that may not conform to standard Langstroth dimensions, accommodating different hive types or personal preferences for frame construction.

Service and Reliability

Manufacturers often provide a warranty and lifelong service. This offers a degree of investment protection and ensures the user has access to technical support for maintenance, troubleshooting, and repairs over the life of the machine.

Understanding the Trade-offs

While highly efficient, investing in a specialized machine involves clear trade-offs that must be considered.

Specialization vs. Versatility

This machine is exceptionally good at one task: making beehive frame components. However, its high degree of specialization means it cannot be used for general-purpose woodworking tasks, unlike a table saw or router.

Initial Investment vs. Long-Term Cost

The upfront cost of a dedicated frame-making machine is significant compared to using a collection of general-purpose tools. The investment is justified by reduced labor time, increased throughput, and superior consistency, which can lead to lower per-frame costs over the long run.

Production Scale

The "compact" nature of the machine suggests it is best suited for small to medium-sized operations. Large-scale commercial apiaries producing tens of thousands of frames may require industrial-grade, higher-throughput automated systems.

Making the Right Choice for Your Operation

Deciding whether to invest in this machine depends entirely on your operational goals.

- If your primary focus is increasing production speed and consistency: This machine is a direct solution, as it automates complex cuts and reduces manual error.

- If your primary focus is managing a non-standard or custom hive setup: The machine's adjustability provides the control needed to produce frames that fit your specific requirements.

- If your primary focus is minimizing upfront equipment costs for a small hobby operation: Continuing to use general-purpose woodworking tools is the more economical path, though it will require more time and skill.

Ultimately, this machine is an investment in process optimization, designed for the serious beekeeper who values precision and efficiency in their craft.

Summary Table:

| Component | Key Machining Functions |

|---|---|

| Top Bars | Double-end grooving, L-tenon forming |

| Side Bars | Sidebar drilling, double-end grooving, double-end edge milling |

| Bottom Bars | Double-end straight tenon, bottom bar grooving |

| Overall Machine | Compact & portable design, customizable frame designs, warranty & service |

Ready to optimize your frame production with professional-grade equipment?

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through wholesale-focused operations. Our Beehive Frame Making Machines are designed to deliver the precision, speed, and consistency your business needs to scale.

Contact us today to discuss your requirements and discover how our solutions can enhance your operation's efficiency and profitability.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- What role does standardized wooden beehive manufacturing machinery play? Scale Your Apiary with Industrial Precision

- What is an automatic sidebar forming machine? Automate High-Volume Beehive Frame Production

- What are the key maintenance practices for beehive frames? Ensure Hive Health & Maximize Productivity

- What is the difference between assembled and unassembled beehive frames? Save Time or Money for Your Hive

- How should wooden hive components be cared for before use? Essential Steps for Longevity & Bee Health