In short, an automatic sidebar forming machine is a specialized piece of industrial equipment designed for one specific purpose: to automatically manufacture the sidebars of beehive frames. It transforms raw material into finished components, forming a critical part of the production line for beekeeping supplies.

The core purpose of this machine is to shift beehive frame production from a manual, labor-intensive task to a high-volume, automated process. Its value is realized in dramatically increased production speed and reduced labor costs for commercial-scale operations.

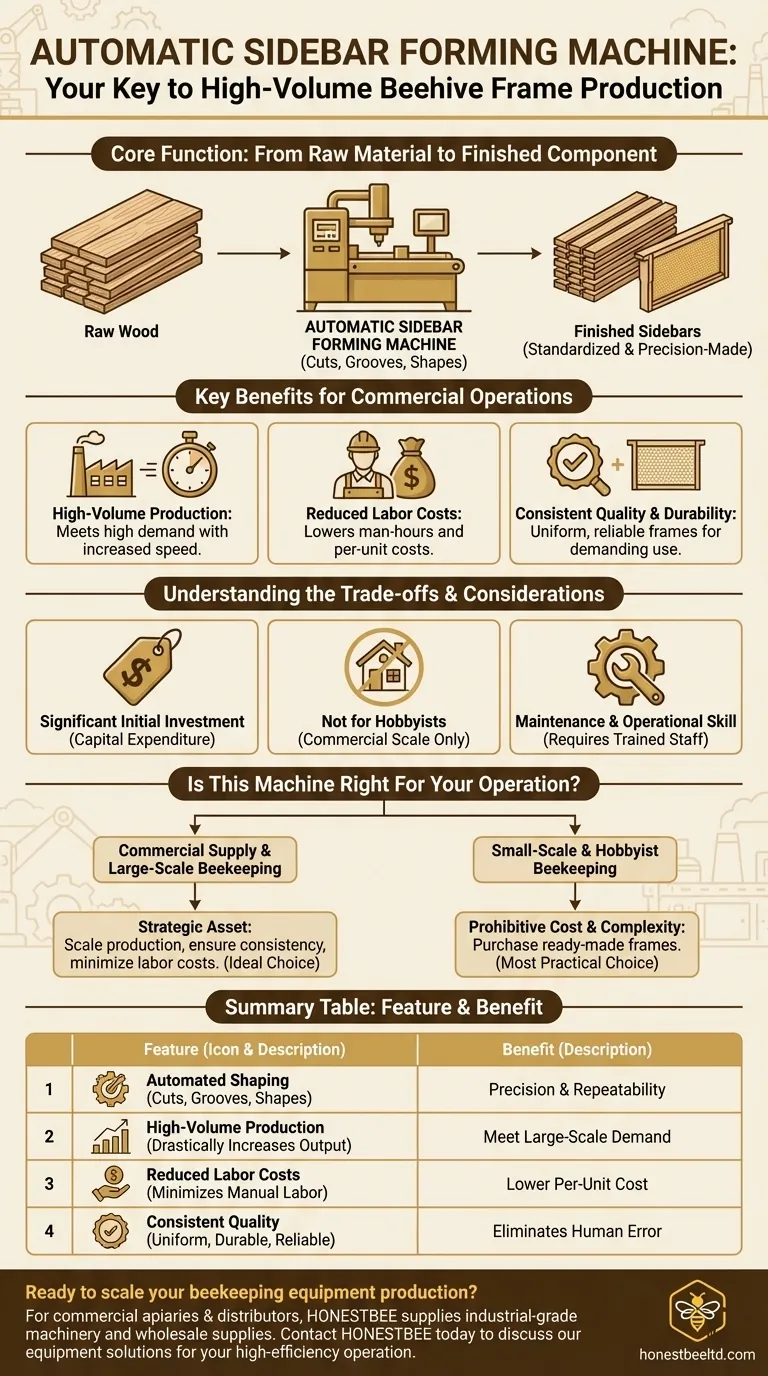

The Core Function: From Raw Material to Finished Component

An automatic sidebar forming machine is not a general-purpose woodworking tool. It is a highly specialized asset built to solve a specific bottleneck in the manufacturing of beekeeping equipment.

Automated Shaping

The machine automates the entire process of shaping a piece of wood into a beehive frame sidebar. This includes cutting, grooving, and shaping the wood to precise, repeatable specifications.

Designed for Beekeeping

Every aspect of the machine is optimized for the unique requirements of beehive frames. The dimensions and features it creates are standardized for compatibility within modern apiaries.

Key Benefits for Commercial Operations

The adoption of such a machine is driven by clear economic and operational advantages. It addresses the primary challenges of producing beekeeping equipment at scale.

High-Volume Production

Its primary benefit is the ability to produce a vast number of sidebars quickly and efficiently. This allows manufacturers to meet high demand without a proportional increase in manual labor.

Reduced Labor Costs

By automating a time-consuming task, the machine significantly reduces the man-hours required for frame production. This directly translates to lower labor costs and a more competitive price per unit.

Consistent Quality and Durability

Automation eliminates human error, ensuring every sidebar is identical. The resulting frames are uniform and durable, capable of withstanding the demanding conditions inside a beehive and the wear of regular handling.

Understanding the Trade-offs

While powerful, this machine is a strategic investment with specific considerations. It is not a universal solution for everyone involved in beekeeping.

Significant Initial Investment

This is a piece of industrial machinery, representing a substantial capital expenditure. The upfront cost is significant and must be justified by a high volume of production.

Not for Hobbyists or Small Apiaries

The economic benefits of this machine are only realized at a commercial scale. Hobbyists or small-scale beekeepers would find purchasing pre-made frames or manual assembly far more cost-effective.

Maintenance and Operational Skill

Like any industrial equipment, an automatic sidebar forming machine requires regular maintenance and skilled operators to run effectively and safely. This adds an operational overhead that must be factored in.

Is This Machine Right for Your Operation?

Evaluating whether to invest in this technology depends entirely on the scale and goal of your enterprise.

- If your primary focus is commercial supply: This machine is a fundamental tool for scaling production, ensuring product consistency, and minimizing per-unit labor costs.

- If your primary focus is a large-scale beekeeping operation: This investment can provide vertical integration, giving you direct control over the quality, cost, and availability of your own equipment.

- If your primary focus is small-scale or hobbyist beekeeping: The cost and complexity are prohibitive; purchasing ready-made frames is the most practical and economical choice.

Ultimately, an automatic sidebar forming machine is a strategic asset for transforming beehive frame production into a high-efficiency industrial process.

Summary Table:

| Feature | Benefit |

|---|---|

| Automated Shaping | Cuts, grooves, and shapes wood with precision and repeatability. |

| High-Volume Production | Drastically increases output to meet large-scale commercial demand. |

| Reduced Labor Costs | Lowers per-unit cost by minimizing manual labor requirements. |

| Consistent Quality | Ensures every frame sidebar is uniform, durable, and reliable. |

Ready to scale your beekeeping equipment production?

For commercial apiaries and beekeeping equipment distributors, HONESTBEE supplies the industrial-grade machinery and wholesale supplies needed to build a high-efficiency operation. An automatic sidebar forming machine is a core investment for achieving scalable, cost-effective frame production.

Contact HONESTBEE today to discuss how our equipment solutions can transform your manufacturing process and boost your profitability.

Visual Guide

Related Products

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- What functionalities does the Beehive Frame Making Machine offer? A Complete Guide to Automated Frame Production

- How does industrial-grade woodworking machinery contribute to standardized beehive manufacturing? Precision at Scale

- What is the difference between assembled and unassembled beehive frames? Save Time or Money for Your Hive

- Why is high-performance beehive manufacturing equipment critical? Boost Colony Survival and Apiary Resilience

- What are the key maintenance practices for beehive frames? Ensure Hive Health & Maximize Productivity