At its core, a metal sieve is a tool designed for the precise separation of particles. It functions by allowing smaller particles or liquids to pass through a woven wire mesh while retaining larger particles, effectively acting as a filter or a grader for various materials.

A metal sieve's value extends beyond simple straining; its primary advantage lies in the material's durability, chemical resistance, and the precision of its mesh, making it indispensable for tasks requiring reliable and repeatable separation in both culinary and industrial environments.

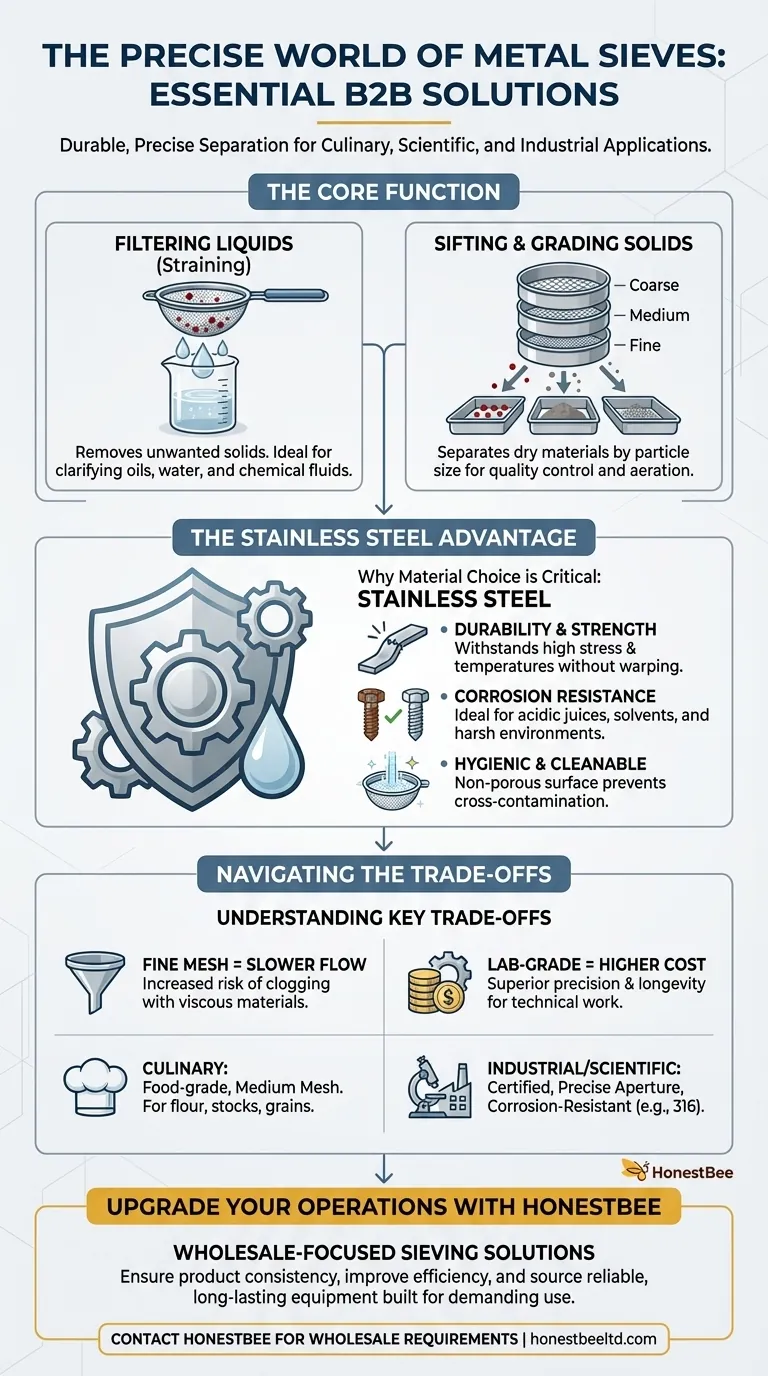

The Core Function: Precise Particle Separation

A sieve's purpose is to separate one substance from another. Depending on the application, this can mean filtering solids from a liquid or grading dry particles by size.

Filtering Solids from Liquids

The most common use for a metal sieve is to act as a strainer. The mesh allows liquid to pass through while catching unwanted solid impurities.

Because materials like stainless steel are highly corrosion-resistant, they are ideal for filtering a wide array of liquids. This includes removing fine particulates from tap water, clarifying used cooking oils, or even filtering contaminants from motor oils and other industrial fluids.

Sifting and Grading Solids

Metal sieves are also essential for separating dry materials based on particle size. This process is often called sifting or grading.

In a culinary setting, this means aerating flour or removing lumps from powdered sugar. In industrial or scientific contexts, a stack of sieves with progressively finer mesh is used to sort materials like sand, powders, or grains into specific size ranges for quality control and analysis.

Why Material Choice is Critical

The "metal" in a metal sieve is not just for structure; it defines the tool's performance, lifespan, and appropriate use cases.

Stainless Steel: The Industry Standard

Stainless steel is the most common material for high-quality sieves due to its unique combination of properties.

It is exceptionally durable, able to withstand high temperatures and physical stress without warping. Its non-porous surface is easy to clean and sanitize, preventing cross-contamination. Most importantly, its resistance to rust and corrosion makes it safe for filtering everything from acidic fruit juices to chemical solvents.

Mesh Count and Aperture Size

The defining characteristic of any sieve is its mesh. Mesh count refers to the number of wires per inch, while aperture size is the actual size of the openings between the wires.

A higher mesh count results in a smaller aperture size, enabling finer filtration. This specification is critical in scientific and industrial applications where separation must be precise and repeatable.

Understanding the Trade-offs

While incredibly useful, choosing and using a metal sieve involves balancing competing factors. Understanding these trade-offs is key to achieving your goal effectively.

Fineness vs. Flow Rate

A very fine mesh (high mesh count) will capture extremely small particles, but it will also slow down the flow of liquid or material passing through it. This can also make the sieve more susceptible to clogging, especially with viscous liquids or materials with a high concentration of solids.

Durability vs. Cost

Certified, lab-grade stainless steel sieves with precise, documented aperture sizes are significantly more expensive than standard kitchen strainers. While the initial cost is higher, they provide superior longevity, reliability, and the accuracy required for technical work.

Potential for Clogging and Wear

No sieve is immune to clogging. Fine meshes require regular and thorough cleaning to maintain performance. Over time, abrasive materials can cause wear on the mesh wires, potentially altering the aperture size and reducing the sieve's accuracy.

Selecting the Right Sieve for Your Task

Your specific goal will determine the ideal sieve specifications.

- If your primary focus is culinary preparation: A food-grade stainless steel sieve with a medium mesh count is versatile for sifting flour, rinsing grains, and straining stocks.

- If your primary focus is scientific analysis: You must use a certified sieve with a documented, precise aperture size to ensure your results are accurate and repeatable.

- If your primary focus is industrial filtering: Prioritize a sieve made from a corrosion-resistant alloy like 316 stainless steel, which can handle aggressive chemicals and high temperatures.

Ultimately, choosing the correct metal sieve is a matter of matching the material and mesh precision to the demands of your task.

Summary Table:

| Application | Primary Function | Key Sieve Characteristic |

|---|---|---|

| Culinary Preparation | Sifting flour, straining stocks, rinsing grains | Food-grade stainless steel, medium mesh |

| Scientific Analysis | Precise particle size grading for quality control | Certified, precise aperture size, lab-grade |

| Industrial Filtering | Removing contaminants from oils, chemicals, water | Corrosion-resistant alloy (e.g., 316 stainless steel) |

Upgrade Your Operations with Professional-Grade Sieving Solutions

Whether you're a commercial apiary managing pollen and wax or a distributor supplying beekeeping equipment, precise particle separation is critical for quality control. HONESTBEE supplies durable, corrosion-resistant stainless steel sieves and other essential beekeeping supplies built for demanding, high-volume use.

We provide wholesale-focused solutions to help you:

- Ensure product consistency and purity.

- Improve efficiency with reliable, long-lasting equipment.

- Source high-quality tools tailored to commercial and industrial needs.

Contact HONESTBEE today to discuss your wholesale supply requirements and discover the right equipment for your business.

Visual Guide

Related Products

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Stainless Steel Honey Press Wax Press with Tank

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What are some typical mesh size combinations found in double sieve honey strainers? Expert Guide to Honey Filtration

- What is the primary purpose of honey filters? Achieve Professional Clarity & Pure Honey Quality

- What is the procedure for managing a brood nest restricted by honey or pollen? Restore Space for Queen Laying

- How does a multi-layer stainless steel honey strainer improve quality? Ensure Pure, Professional-Grade Honey Results

- What are the key features of a double sieve honey strainer? Achieve Fast, Clean Honey Processing