At its core, a radial extractor is a machine that uses centrifugal force to harvest honey from honeycomb frames. Its defining feature is how it positions the frames inside the drum: like the spokes of a wheel, with the top bars facing outward. This unique orientation allows honey to be extracted from both sides of the frames simultaneously, significantly speeding up the harvesting process.

The primary purpose of a radial extractor is to maximize efficiency. By eliminating the need to stop and manually flip frames, it dramatically reduces the time and labor required for honey extraction, making it the preferred choice for beekeepers with more than a few hives.

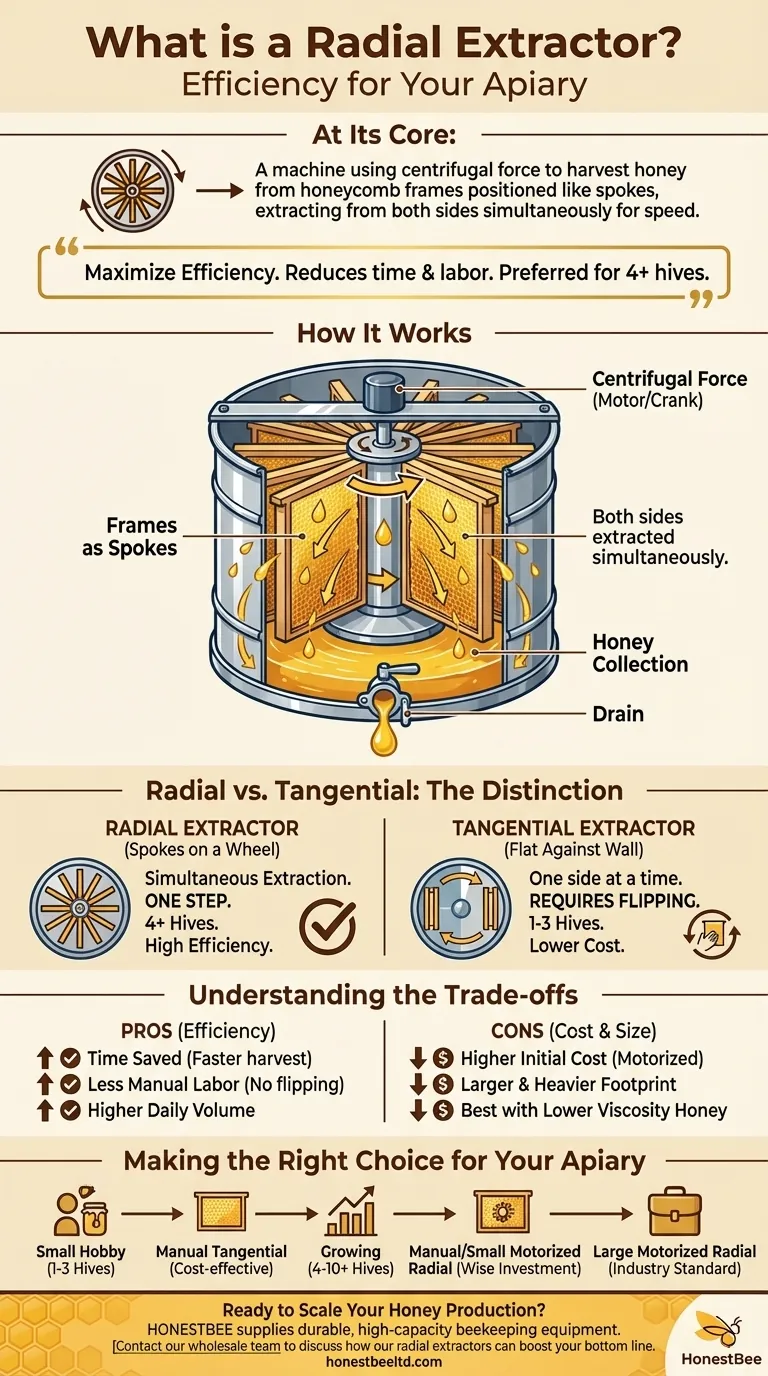

How a Radial Extractor Works

A radial extractor's design is simple but highly effective. It revolves around a central rotor inside a large stainless steel drum, all geared towards one goal: getting honey out of the comb quickly and cleanly.

The 'Spokes on a Wheel' Design

The frames are loaded vertically into slots in the rotor, radiating out from the center. The top bar of each frame, which is the thickest wooden part, faces the outer wall of the drum. This ensures the frame has maximum structural support during the extraction process.

The Power of Centrifugal Force

Once the extractor is loaded and the lid is secured, the rotor begins to spin, either by a hand crank or an electric motor. This rotation generates powerful centrifugal force, which flings the honey outwards from the honeycomb cells and onto the inner wall of the drum.

Simultaneous Extraction

Because the frames are positioned like spokes, the force acts on both sides of the comb at the same time. Honey flows down the drum wall and collects at the bottom, where it can be drained through a spigot or honey gate. This "extract-once" process is the radial extractor's main advantage.

Radial vs. Tangential: The Critical Distinction

Understanding the radial extractor requires comparing it to its counterpart, the tangential extractor. The choice between them is one of the most significant equipment decisions a beekeeper will make.

Tangential Extractors: One Side at a Time

A tangential extractor holds the frames flat against the inside wall of the drum. When it spins, it only extracts honey from the outward-facing side of the comb. The beekeeper must then stop the machine, manually flip each frame, and spin it a second time to extract from the other side.

Radial Extractors: Built for Volume

Radial extractors, which can hold anywhere from 6 to over 80 frames, bypass this two-step process entirely. This efficiency gain becomes exponential as the number of hives grows. What might take a full day with a tangential extractor could be done in a few hours with a radial model.

Understanding the Trade-offs

While highly efficient, a radial extractor is not the automatic choice for every beekeeper. Objectively weighing its pros and cons is essential.

The Efficiency Advantage

For any beekeeper managing more than a handful of colonies, the time saved during harvest is the single biggest benefit. A radial design minimizes manual labor, reduces physical strain, and dramatically increases the amount of honey you can process in a day.

The Cost and Size Factor

This efficiency comes at a price. Radial extractors are generally larger, heavier, and more expensive than tangential extractors with a similar frame capacity. Motorized versions represent a significant financial investment compared to manual crank models.

Honey Viscosity Considerations

Radial extraction works best with lower-viscosity (runnier) honey. The force is applied at an angle to the cells. For very thick, viscous honey, a tangential extractor can sometimes be more effective because the force is applied directly perpendicular to the comb, pulling the honey straight out.

Making the Right Choice for Your Apiary

Your decision should be based on the current scale and future goals of your beekeeping operation.

- If your primary focus is a small hobby with 1-3 hives: A small, manual tangential extractor is often the most cost-effective and practical choice.

- If your primary focus is growing your apiary to 4-10+ hives: A manual or small motorized radial extractor is a wise investment that will pay for itself in time and labor savings.

- If your primary focus is a commercial or serious sideliner business: A large, motorized radial extractor is the industry standard and an essential tool for efficient workflow.

Ultimately, choosing the right extractor is about matching the tool's efficiency to the scale of your beekeeping ambitions.

Summary Table:

| Feature | Radial Extractor | Tangential Extractor |

|---|---|---|

| Frame Orientation | Spokes of a wheel | Flat against the drum wall |

| Extraction Process | Both sides simultaneously | One side at a time (requires flipping) |

| Best For | 4+ hives, commercial operations | 1-3 hives, small hobbyists |

| Key Advantage | Maximum speed and efficiency | Lower initial cost |

Ready to Scale Your Honey Production?

For commercial apiaries and beekeeping equipment distributors, a radial extractor is not just a tool—it's an investment in productivity. HONESTBEE supplies the durable, high-capacity beekeeping equipment you need to streamline your harvest and boost your bottom line.

Contact our wholesale team today to discuss how our radial extractors can become the efficient heart of your operation.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

People Also Ask

- How is honey harvested from Langstroth hives? A Guide to Efficient, Comb-Preserving Extraction

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- How do automatic honey extractors function? Achieve High-Efficiency Honey Harvesting

- Can a manual extractor be upgraded to an electric one? Save Labor & Boost Efficiency

- How have centrifuge honey extractors impacted honey harvesting? Boosting Efficiency and Sustainability