In terms of pure filtration capability, a 100-micron filter is "better" because its pores are smaller, allowing it to capture finer particles that a 200-micron filter would let pass through. Each micron rating is designed to remove contaminants larger than its specified pore size, so a lower number always corresponds to finer filtration.

The question is not which filter is better in a vacuum, but which is the right tool for your specific objective. Choosing incorrectly leads to either insufficient filtration or, more commonly, rapid clogging, reduced flow rates, and unnecessary maintenance.

What a Micron Rating Actually Means

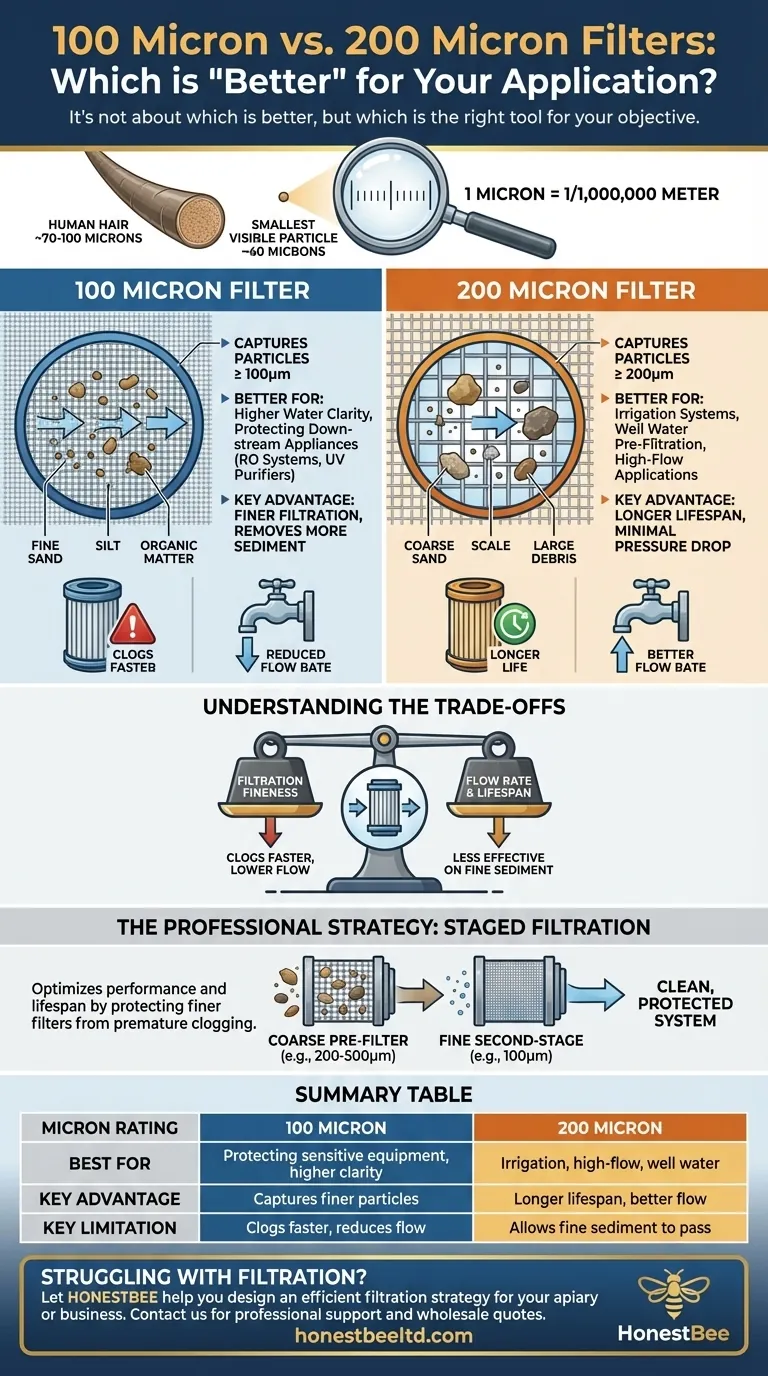

A micron, short for micrometer, is a unit of measurement equal to one-millionth of a meter. To put this in perspective, a typical human hair is about 70-100 microns in diameter, and the smallest particle visible to the naked eye is around 40 microns.

The 100-Micron Filter

A filter with a 100-micron rating will capture particles that are 100 microns in size or larger. This includes contaminants like fine sand, silt, and some larger-scale organic matter. It effectively removes most visible sediment from water.

The 200-Micron Filter

A 200-micron filter has pores twice as large. It is designed to capture larger debris such as coarse sand, scale, and other significant particulates. It will allow finer sediment to pass through easily.

Why "Better" Depends on Your Goal

The effectiveness of a filter is measured by how well it achieves your specific goal, whether that's protecting sensitive equipment, removing visible debris, or simply pre-treating water for further filtration.

The Case for Finer Filtration (100 Microns)

A 100-micron filter is the superior choice when your primary goal is to achieve a higher level of water clarity or to protect downstream appliances. Water heaters, UV purifiers, and especially Reverse Osmosis (RO) systems benefit from having finer sediment removed beforehand, extending their operational life.

The Case for Coarser Filtration (200 Microns)

A 200-micron filter is often the more practical choice when the goal is simply to remove large, obvious debris without significantly impeding water flow. This makes it ideal for irrigation systems, as a first-stage pre-filter for well water, or in any application where maintaining high flow rate and pressure is more critical than removing fine silt.

Understanding the Critical Trade-offs

Selecting a filter is a balancing act. Opting for the smallest micron rating without understanding the consequences is a common mistake.

Filtration Fineness vs. Flow Rate

This is the most fundamental trade-off. The smaller the filter's pores, the more it restricts the flow of water. Installing a 100-micron filter where a 200-micron would suffice can lead to a noticeable drop in water pressure throughout your system.

Filtration Fineness vs. Filter Lifespan

A finer filter captures more particles, which means it will clog much faster. In water with high sediment levels, a 100-micron filter may require frequent cleaning or replacement, while a 200-micron filter would continue to operate effectively for much longer.

The Staged Filtration Strategy

Professionals rarely choose just one. The most effective and low-maintenance approach is often staged filtration. A coarser pre-filter (like 200 or 500 microns) is installed first to capture the large debris. This protects the finer, second-stage filter (like 100 microns) from clogging prematurely, optimizing both performance and lifespan for the entire system.

Making the Right Choice for Your System

Base your decision on the specific problem you are trying to solve and the level of maintenance you are willing to perform.

- If your primary focus is maximum clarity and protecting sensitive equipment: A 100-micron filter is the correct starting point, but be prepared for potential pressure loss and more frequent service.

- If your primary focus is removing only large debris with minimal impact on flow: A 200-micron filter is the more robust and lower-maintenance choice.

- If your primary focus is creating an efficient, long-lasting system for high-sediment water: Implement a staged system, using a 200-micron filter to protect a subsequent 100-micron filter.

Ultimately, the best filter is the one that effectively resolves your specific issue without creating new problems.

Summary Table:

| Micron Rating | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| 100 Micron | Protecting sensitive equipment (RO systems, UV purifiers), achieving higher water clarity | Captures finer particles like silt and fine sand | Clogs faster, reduces flow rate more significantly |

| 200 Micron | Irrigation, well water pre-filtration, high-flow applications | Longer lifespan, minimal pressure drop | Allows finer sediment to pass through |

Struggling with sediment, low pressure, or frequent filter changes? Let HONESTBEE help you design an efficient filtration strategy. We supply durable, commercial-grade beekeeping supplies and equipment—including water filtration solutions for apiaries and distributors. Our experts can recommend the right micron rating or a staged system to protect your equipment and reduce maintenance.

Contact HONESTBEE today for a wholesale quote and professional support!

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Stainless Steel Honey Filter with Support Handle

People Also Ask

- Why is filtering honey an important step in honey processing? Ensure Purity, Clarity & Marketability

- What is the role of filtration in honey processing? Ensure Purity, Clarity, and Shelf Life

- What are the benefits of drying honey filtering equipment after use? Protect Your Honey Quality & Equipment Investment

- Why is filtering honey considered an essential step in honey processing? Ensure Quality and Commercial Viability

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality