Regardless of hive type, the single most essential task for any beekeeper is to regularly check the colony for signs of disease and pests. While a Flow Hive revolutionizes the honey harvesting process, it does not change the fundamental requirements of animal husbandry. The health and vitality of your bees are paramount.

Many new beekeepers believe a Flow Hive's convenience extends to all aspects of beekeeping, but this is a critical misunderstanding. The technology only alters honey extraction; the core responsibility of managing colony health in the brood box remains identical to that of a traditional Langstroth hive.

Understanding the Two Hive Architectures

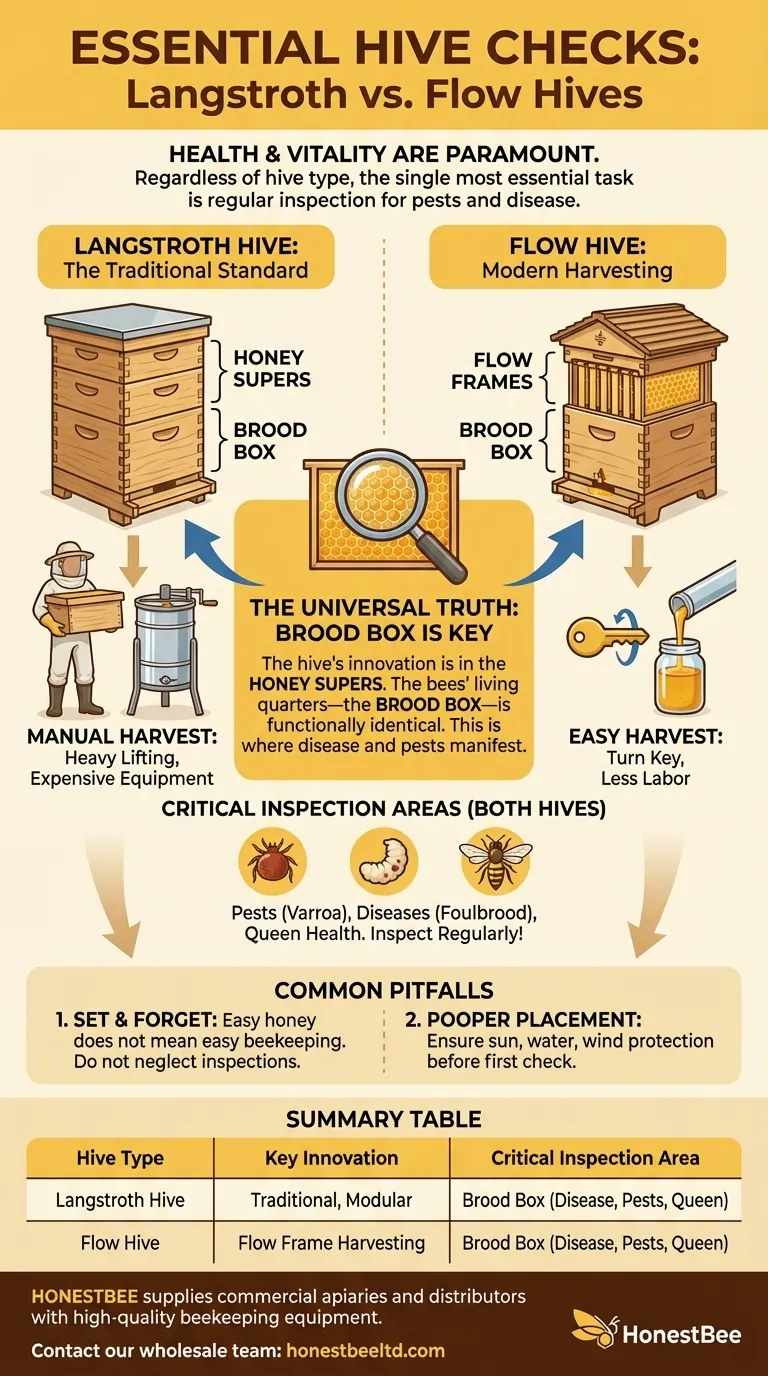

To grasp why the core checks are universal, you must first understand the functional differences and similarities between these two popular hive designs.

The Langstroth Hive: The Traditional Standard

The Langstroth is a modular, vertical hive that has been the industry standard for over a century. It consists of stacked boxes—typically a lower set for the queen to lay eggs (the brood box) and upper boxes for honey storage (the honey supers).

This design is hands-on. Harvesting honey requires removing the heavy supers, transporting them, and using separate, often expensive, equipment like an extractor to spin the honey out of the frames.

The Flow Hive: A Modern Approach to Harvesting

A Flow Hive is built upon a standard Langstroth foundation. It uses a conventional brood box but features specially designed frames in the honey supers.

With the turn of a key, these frames split the honeycomb cells vertically, allowing honey to drain out through a tube without disturbing the bees or removing the super. This significantly reduces the labor and equipment needed for harvesting.

Why Core Health Checks Are Universal

The key takeaway is that the Flow Hive's innovation is confined to the honey supers. The bees' living quarters—the brood box—is functionally the same as in any Langstroth hive, and this is where your attention must be focused.

Disease Doesn't Discriminate by Hive Type

Pests like the Varroa mite and diseases like American Foulbrood affect the bees and their developing young (brood). These issues manifest in the brood box, far away from the honey harvesting mechanism.

A hive can be dying from a pest infestation while the Flow Frames remain full of honey. Your inspection duties are therefore identical and non-negotiable for both systems.

A Healthy Colony is Your First Priority

You cannot harvest a surplus of honey from a weak or dying colony. The primary job of a beekeeper is not honey collection; it is the responsible management of their livestock.

Vigilant and regular inspections to ensure the colony is strong, the queen is laying well, and pest levels are low are the only way to ensure a productive hive, regardless of its design.

Common Pitfalls and Essential Considerations

Building trust with your role as a beekeeper means understanding the common mistakes and trade-offs associated with these hive systems.

The "Set and Forget" Misconception

The biggest risk with the Flow Hive's brilliant design is that it can lull new beekeepers into a false sense of security. The ease of harvesting can lead to neglecting essential internal hive inspections.

Remember: Easy honey harvesting does not mean easy beekeeping. You must still open the hive and inspect the brood frames regularly.

Overlooking Hive Placement

Before your first inspection, an essential one-time check is proper hive placement. This is critical for the success of any colony.

Ensure the hive has morning sun, a nearby water source, minimal wind, and an unobstructed flight path of at least 20 feet. It should also be on a level surface and away from high-traffic areas.

The Cost-Benefit Analysis

The upfront cost of a Flow Hive is generally higher than a basic Langstroth setup. However, the Langstroth requires a later investment in costly extraction equipment.

Your choice should factor in both the initial purchase price and the long-term equipment needs associated with honey harvesting.

Making the Right Choice for Your Goal

Your beekeeping goals should dictate your equipment choice, but your commitment to hive health must remain constant.

- If your primary focus is harvesting convenience: The Flow Hive is an excellent choice, but you must commit to the same rigorous inspection schedule as any other beekeeper.

- If your primary focus is a lower initial cost and a traditional experience: The Langstroth hive is the proven standard, but be prepared to invest in extraction equipment and heavier lifting down the line.

Ultimately, successful beekeeping is determined not by the box the bees live in, but by the diligence and care of the person managing it.

Summary Table:

| Hive Type | Key Innovation | Critical Inspection Area |

|---|---|---|

| Langstroth Hive | Traditional, modular design | Brood box for disease, pests, and queen health |

| Flow Hive | Honey harvesting via Flow Frames | Brood box for disease, pests, and queen health |

Ensure your apiary's success with the right equipment.

Whether you manage Langstroth or Flow Hives, a healthy colony is the foundation of a productive beekeeping operation. Proper equipment is essential for effective inspections and management.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable beekeeping supplies and equipment through our wholesale-focused operations. From hive tools and protective gear to full hive setups, we provide the reliable tools you need to maintain thriving colonies.

Let us equip you for success. Contact our wholesale team today to discuss your apiary's needs and explore our product catalog.

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Honey Flow Garden Bee Hive Flow Hive Best Beehive for Beginners

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

People Also Ask

- What is the role of digital management tools and breeding records in honeybee breeding? Master Data-Driven Selection

- Why is professional beehive transportation and lifting equipment necessary? Maximize Your Migratory Beekeeping Yield

- What is the technical significance of capped honey for beekeepers? Ensuring Maturity and Stability

- What factors should be considered when choosing a location for a honeybee hive? Optimize Colony Health & Productivity

- What role do precision monitoring sensors and IT diagnostic solutions play in honeybee health management?

- What critical data points do industrial smart scales provide? Optimize Your Apiary with Real-Time Smart Hive Insights

- How are industrial-grade weighing instruments used to measure honey production? Optimize Your Apiary's Economic Efficiency

- Why is industrial-grade low-temperature storage equipment necessary for honeybee specimens? Ensure Sample Integrity