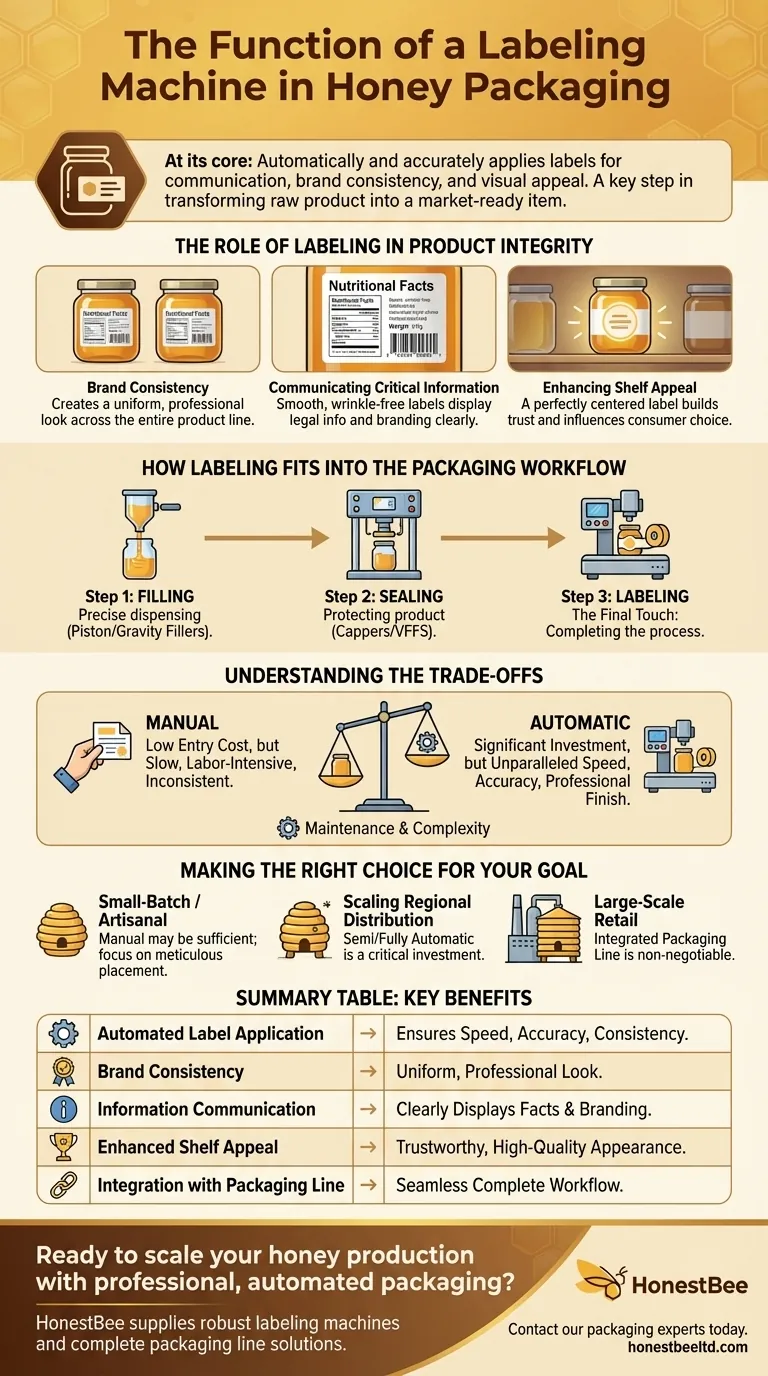

At its core, a labeling machine's function in honey packaging is to automatically and accurately apply labels to jars, pouches, or other containers. This process is critical for communicating essential product information, ensuring brand consistency, and enhancing the product's visual appeal for consumers on the shelf.

The real function of a labeling machine goes beyond simply sticking on a label. It represents the final, crucial step in a system designed to transform a raw product into a professional, market-ready item, ensuring every container meets a consistent standard of quality and presentation.

The Role of Labeling in Product Integrity

A label is more than just a name; it is a direct line of communication with your customer. Automating its application ensures this communication is always clear and professional.

Ensuring Brand Consistency

Manually applying labels often results in slight variations in placement and angle. An automated labeling machine places every label in the exact same position, creating a uniform, professional look across your entire product line that reinforces brand quality and reliability.

Communicating Critical Information

Labels contain legally required information like nutritional facts, weight, and origin, as well as branding. A machine ensures these labels are applied smoothly and without wrinkles, making them easy to read and lending credibility to your product.

Enhancing Shelf Appeal

A perfectly centered, crisp label makes a product look trustworthy and high-quality. This professional finish is often the deciding factor for a consumer choosing between two similar products on a crowded shelf.

How Labeling Fits into the Packaging Workflow

Labeling doesn't happen in isolation. It is the final stage of a larger, often automated process designed for efficiency and quality control.

Step 1: Filling the Container

The process begins with a filling machine. Piston honey filling machines are common, using a piston to dispense precise, accurate amounts of viscous honey into each container. For less viscous liquids, gravity fillers may be used.

Step 2: Sealing the Product

Once filled, the container must be sealed to protect the honey. For jars, this is typically a capping machine. For flexible packaging like pouches or sachets, a VFFS (Vertical Form Fill Seal) machine handles the entire process: it forms the pouch from a film roll, fills it with honey, and then seals it shut.

Step 3: The Final Touch: Labeling

After the container is filled and sealed, it moves to the labeling machine. This machine applies the pre-printed labels to the jars or pouches, completing the packaging process and making the product ready for distribution.

Understanding the Trade-offs

Automating your packaging line, including labeling, is a significant step that involves clear benefits and necessary considerations.

Initial Investment vs. Long-Term Efficiency

The primary trade-off is cost. Manual labeling has a very low entry cost but is slow, labor-intensive, and prone to inconsistency. An automatic labeling machine requires a significant upfront investment but delivers unparalleled speed, accuracy, and a professional finish that is essential for scaling production.

Flexibility and Setup Time

Automated machines are optimized for specific container shapes and label sizes. Changing between different jar sizes or label designs requires recalibration and setup time, which can slow down production for operations with highly varied product lines.

Maintenance and Complexity

Like any machinery, fillers and labelers require routine maintenance and skilled operation. This is a manageable, but necessary, part of shifting from a manual process to an automated one.

Making the Right Choice for Your Goal

Your approach to labeling should directly support your production volume and brand ambitions.

- If your primary focus is small-batch, artisanal sales: Manual labeling may be sufficient, but pay meticulous attention to consistent placement to build a professional brand image from the start.

- If your primary focus is scaling regional distribution: A semi-automatic or fully automatic labeling machine is a critical investment to ensure your product looks professional and can be produced efficiently.

- If your primary focus is large-scale retail: An integrated packaging line, from a high-speed filler to a fully automatic labeler, is non-negotiable for meeting demand and maintaining quality control.

Ultimately, effective labeling validates the quality of the honey inside the container, turning a simple product into a trusted brand.

Summary Table:

| Function | Key Benefit |

|---|---|

| Automated Label Application | Ensures speed, accuracy, and consistency for every container. |

| Brand Consistency | Creates a uniform, professional look that reinforces quality. |

| Information Communication | Clearly displays required nutritional facts, weight, and branding. |

| Enhanced Shelf Appeal | Makes products look trustworthy and high-quality to consumers. |

| Integration with Packaging Line | Works seamlessly with fillers and cappers for a complete workflow. |

Ready to scale your honey production with professional, automated packaging?

At HONESTBEE, we supply robust labeling machines and complete packaging line solutions—including piston fillers and cappers—designed for the needs of commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get the reliable equipment you need to build a trusted brand and meet growing demand.

Contact our packaging experts today to discuss the right labeling solution for your operation.

Visual Guide

Related Products

- Automatic In-Line Flat Surface Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What role does a labeling system play in honey quality traceability and brand protection? Secure Your Market Reputation

- What are the key components of an automatic labeling machine? Unlock High-Speed, Precision Labeling

- Why are professional product labeling and packaging design tools indispensable? Elevate Your Beekeeping Brand Identity

- What is the function of back and neck labels in organic honey branding? Secure Compliance and Elevate Market Value

- What impact do honey-themed cultural merchandise and high-quality packaging design have on the stingless bee industry?

- What are the benefits of using labeling machines? Boost Speed, Accuracy & Brand Image

- Why are automated labeling and coding systems essential for the traceability of certified honey products? Verify Origin

- How does the implementation of batch numbers on honey packaging facilitate quality traceability and food safety?