At its core, a honey bottle labeling machine reduces human error by replacing subjective, variable human action with objective, repeatable mechanical precision. It automates the positioning, application, and validation of labels, ensuring every single bottle is labeled with the exact same accuracy and consistency, which is simply not achievable through manual processes.

The fundamental problem with manual labeling isn't a lack of care; it's the inevitability of human variability. A labeling machine solves this by transforming labeling from a manual craft into a standardized, engineered process, directly protecting brand integrity and operational efficiency.

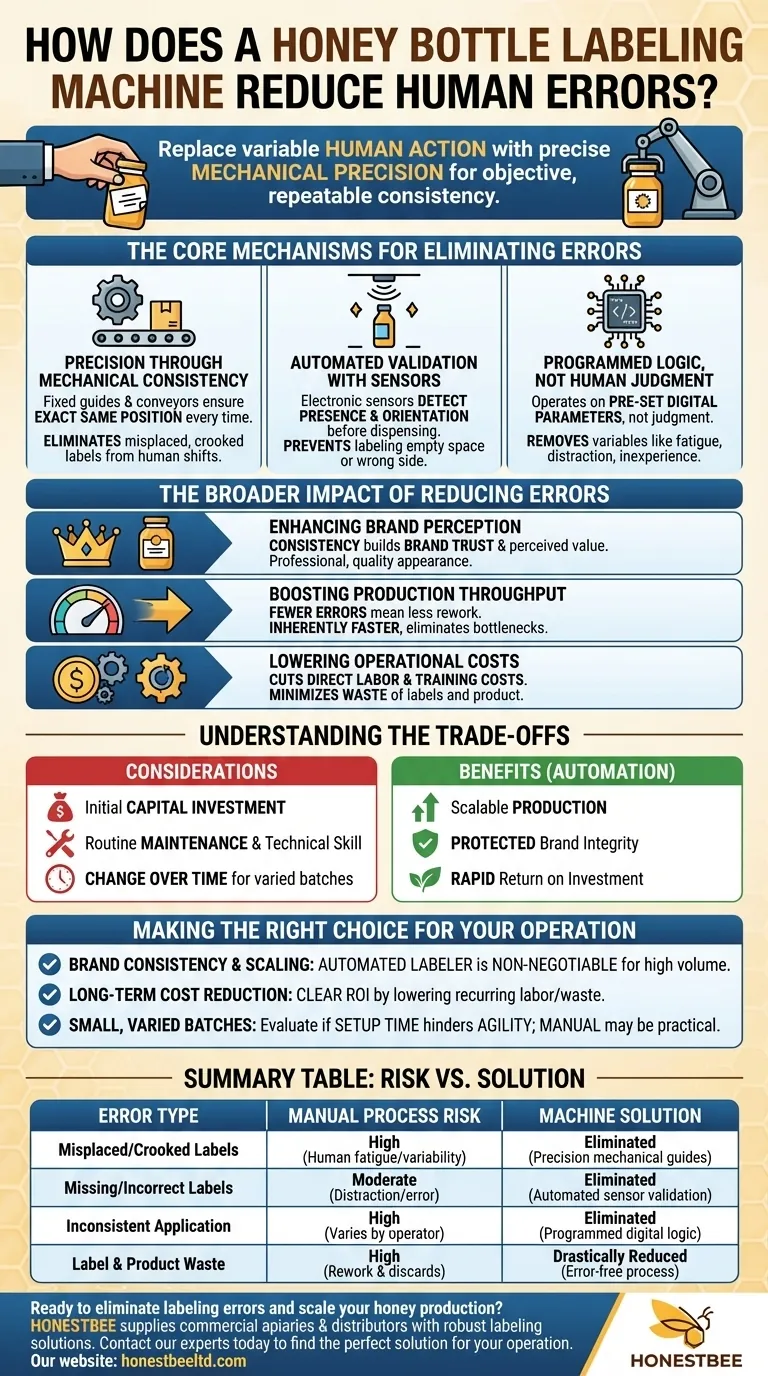

The Core Mechanisms for Eliminating Errors

To understand the value, you must first understand the specific mechanical and logical functions that remove the points of failure inherent in manual work.

Precision Through Mechanical Consistency

A machine uses fixed guides, conveyors, and applicators that physically constrain the bottle and the label.

Every bottle is moved to the exact same position for application. This eliminates misplaced, crooked, or off-center labels that can result from slight shifts in human hand placement over a long day.

Automated Validation with Sensors

Modern labelers use a series of electronic sensors to ensure the process happens correctly.

These sensors detect the presence and orientation of the bottle before a label is even dispensed. This prevents the machine from applying a label to an empty space on the conveyor or putting a front label on the back of a round jar.

Programmed Logic, Not Human Judgment

The machine operates based on pre-set digital parameters—not on an operator's judgment call.

This removes variables like fatigue, distraction, or inexperience, which are primary drivers of inconsistent application, backward labels, or even applying the wrong label roll to a batch of products.

The Broader Impact of Reducing Errors

Eliminating simple labeling mistakes has a cascading positive effect on your entire operation, moving far beyond just aesthetics.

Enhancing Brand Perception

A perfectly placed label signals professionalism and quality to the consumer before they even open the bottle.

Consistency across thousands of units on a store shelf builds brand trust and perceived value, while crooked or bubbled labels can make a premium product look cheap.

Boosting Production Throughput

Fewer errors mean less time spent on rework and quality control.

A consistent, automated process is inherently faster and eliminates the production bottlenecks caused by stopping the line to fix incorrectly labeled products, directly increasing your output.

Lowering Operational Costs

The financial benefits are twofold: reduced labor and minimized waste.

You require fewer operators to achieve a higher output, significantly cutting direct labor and training costs. Furthermore, you waste fewer labels and less product from batches that need to be discarded due to incorrect labeling.

Understanding the Trade-offs

While highly effective, an automated labeler is a strategic choice with clear trade-offs that must be considered.

Initial Capital Investment

The most significant factor is the upfront cost. An automated machine is a capital expenditure, whereas manual labeling is a more flexible operational expense.

Maintenance and Technical Skill

These machines require routine maintenance and calibration to perform optimally. Your staff will also need the technical skills to operate the equipment and troubleshoot minor issues.

Flexibility for Varied Batches

Changing the machine's setup for a different bottle size or label design takes time. For very small, highly varied artisanal runs, the changeover time can sometimes negate the speed benefits over nimble manual application.

Making the Right Choice for Your Operation

Ultimately, the decision to invest in a honey bottle labeling machine depends on your specific production goals.

- If your primary focus is brand consistency and scaling production: An automated labeler is a non-negotiable tool for achieving professional-grade product presentation at high volume.

- If your primary focus is long-term cost reduction: The machine provides a clear return on investment by drastically lowering recurring labor costs and material waste.

- If your primary focus is small, artisanal batches with frequent changeovers: Carefully evaluate if the machine's setup time will hinder your agility, as manual labeling may remain more practical.

Choosing the right labeling method is a strategic decision that directly impacts your brand's perception and your operational capacity.

Summary Table:

| Error Type | Manual Process Risk | Machine Solution |

|---|---|---|

| Misplaced/Crooked Labels | High (Human fatigue/variability) | Eliminated (Precision mechanical guides) |

| Missing/Incorrect Labels | Moderate (Distraction/error) | Eliminated (Automated sensor validation) |

| Inconsistent Application | High (Varies by operator) | Eliminated (Programmed digital logic) |

| Label & Product Waste | High (Rework & discards) | Drastically Reduced (Error-free process) |

Ready to eliminate labeling errors and scale your honey production?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, high-performance labeling solutions through our wholesale-focused operations. Our machines are engineered to protect your brand integrity, boost your output, and deliver a rapid return on investment by cutting labor costs and waste.

Contact our experts today to find the perfect labeling solution for your operation.

Visual Guide

Related Products

- Automatic In-Line Flat Surface Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Professional Thermostatic Conical Honey Melter

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What are the advantages and disadvantages of manually applying honey labels? Expert Comparison for Your Brand

- What nutritional information must be included on a honey label? Essential Compliance Guide for Beekeeping Labels

- What role do automated packaging and labeling machines play in the commercialization of honey? Boost Brand Value & Safety

- What functions do automated labeling and traceability systems perform? Ensure Global Honey Compliance and Brand Value

- How does the implementation of batch numbers on honey packaging facilitate quality traceability and food safety?

- How do automated labeling and filling equipment contribute to regulatory compliance for honey production for export?

- What is the function of back and neck labels in organic honey branding? Secure Compliance and Elevate Market Value

- How do honey product packaging and labeling equipment support marketing and traceability? Boost Value and Trust