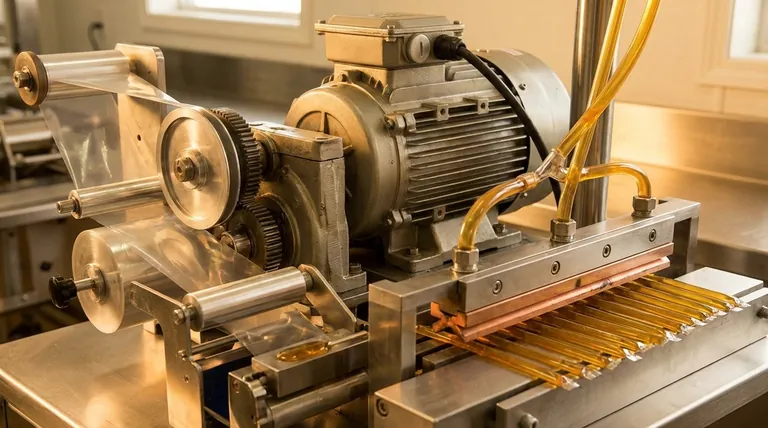

At its core, the motor is the powerhouse of a honey stick machine. It performs the essential function of converting electrical energy into the mechanical motion required to operate the entire packaging system. This single component is responsible for driving key parts like the film rollers that feed the packaging material and the sealing bars that form and separate the individual sticks.

The motor's function goes beyond simple power; it is the orchestrator of the entire automated process, ensuring that every step—from unwinding the packaging film to sealing the final product—happens in perfect synchronization.

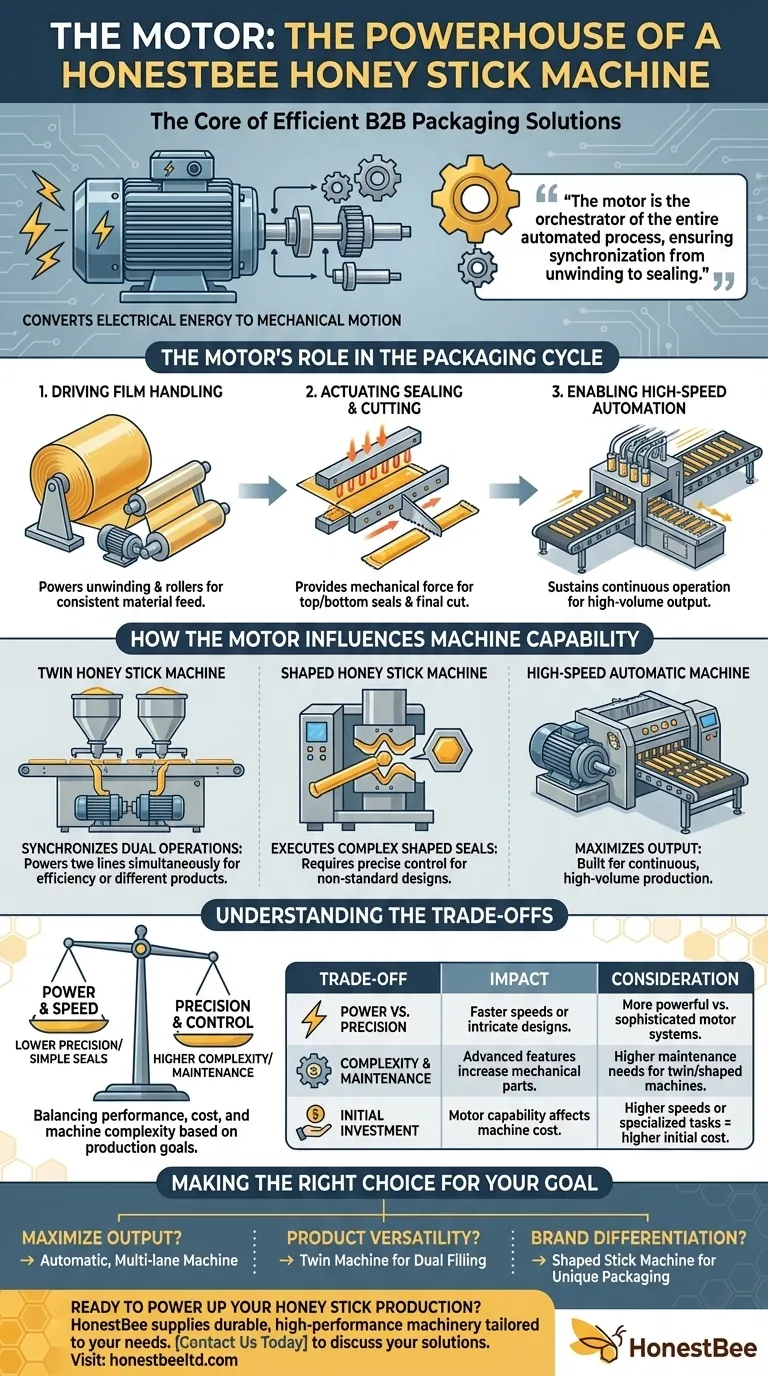

The Motor's Role in the Packaging Cycle

Understanding the motor is understanding how the machine brings a honey stick to life. It drives a precise sequence of mechanical actions that must be flawlessly coordinated.

Converting Power into Motion

The motor is the engine of the machine. It takes electricity from an outlet and transforms it into the physical force needed to run the equipment's moving parts.

Driving the Film Handling System

The packaging process begins with a large roll of film. The motor powers the unwinding disks and film rollers, which pull this material through the machine at a consistent speed, preparing it for filling and sealing.

Actuating Sealing and Cutting Mechanisms

Once the film is filled with honey, the motor provides the mechanical force to operate the sealing bars. These components press together, using heat and pressure to create the top and bottom seals of the honey stick before cutting it free.

How the Motor Influences Machine Capability

The type and power of the motor directly impact the machine's overall performance and features. Different production needs demand different motor capabilities.

Enabling High-Speed Automation

In fully automatic, multi-lane machines, a robust motor is critical. It must sustain high-speed, continuous operation to produce hundreds of honey sticks per minute, handling all steps from loading to unloading without manual intervention.

Synchronizing Dual Operations

For a twin honey stick machine, the motor and its control system are more complex. They must simultaneously power two hoppers and sealing lines, ensuring both sticks are formed and filled with perfect timing to maximize efficiency.

Executing Complex Shaped Seals

A shaped honey stick machine uses unique sealing jaws to create custom, marketable designs. This requires a motor with highly precise control to execute these non-standard sealing patterns accurately on every stick.

Understanding the Trade-offs

While the motor is fundamental, its integration into the machine's design involves balancing performance with cost and complexity.

Power vs. Precision

A more powerful motor can drive faster production speeds. However, tasks like creating shaped seals demand greater precision and control, which can require more sophisticated and expensive motor systems.

Complexity and Maintenance

Advanced machines, like twin or shaped models, rely on more intricate systems driven by the motor. This increased mechanical complexity can lead to higher maintenance needs compared to a standard, single-lane machine.

Initial Investment

The capability of the motor and its associated control systems is a primary factor in the machine's cost. Machines designed for higher speeds or specialized tasks, like the shaped stick machine, naturally command a higher initial investment.

Making the Right Choice for Your Goal

The ideal machine depends entirely on your specific production and marketing objectives.

- If your primary focus is maximizing output: An automatic, multi-lane machine is the most effective choice, as its powerful motor is built for high-volume, continuous production.

- If your primary focus is product versatility: A twin machine allows for filling two different products simultaneously, relying on a motor capable of synchronizing dual production lines.

- If your primary focus is brand differentiation: A shaped stick machine offers unique packaging, but its precise motor control and specialized tooling come at a higher cost.

Ultimately, the motor is the critical component that turns your production goals into a physical reality.

Summary Table:

| Motor Function | Impact on Machine Capability |

|---|---|

| Converts electrical energy to mechanical motion | Enables the entire automated packaging process |

| Drives film rollers and unwinding disks | Ensures consistent material feed for filling |

| Powers sealing and cutting bars | Creates precise seals and separates individual sticks |

| Synchronizes operations in multi-lane or twin machines | Allows for high-speed production or dual-product filling |

| Executes complex shaped seals | Enables unique, brand-differentiating packaging designs |

Ready to power up your honey stick production?

At HONESTBEE, we understand that the right motor is the heart of an efficient packaging line. Whether you're a commercial apiary scaling up or a distributor looking for reliable equipment, our wholesale-focused operations provide robust honey stick machines tailored to your volume and branding needs.

We supply the durable, high-performance machinery that keeps your production running smoothly. Contact us today to discuss how our solutions can help you achieve your packaging goals.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How long do you let honey sit before bottling? Achieve Crystal-Clear Honey for Your Business

- What role do professional honey-filling machines play in the industrialization of stingless bee honey production?

- How does a VFFS liquid packaging machine handle honey packaging? Master Viscous Liquid Filling

- What is the primary value of automated honey-filling machines? Boost Yield and Hygiene Standards

- What are the differences between semi-automatic and fully automatic honey filling machines? A Guide to Choosing the Right Machine for Your Apiary

- How does automated honey filtration and filling machinery improve quality? Guard Your Apiary Against Pest Contamination

- What are the characteristics of Semi-automated honey filling machines? Boost Efficiency for Growing Apiaries

- What role do control systems play in modern honey filling machines? Optimize Your Output with Smart PLC Technology