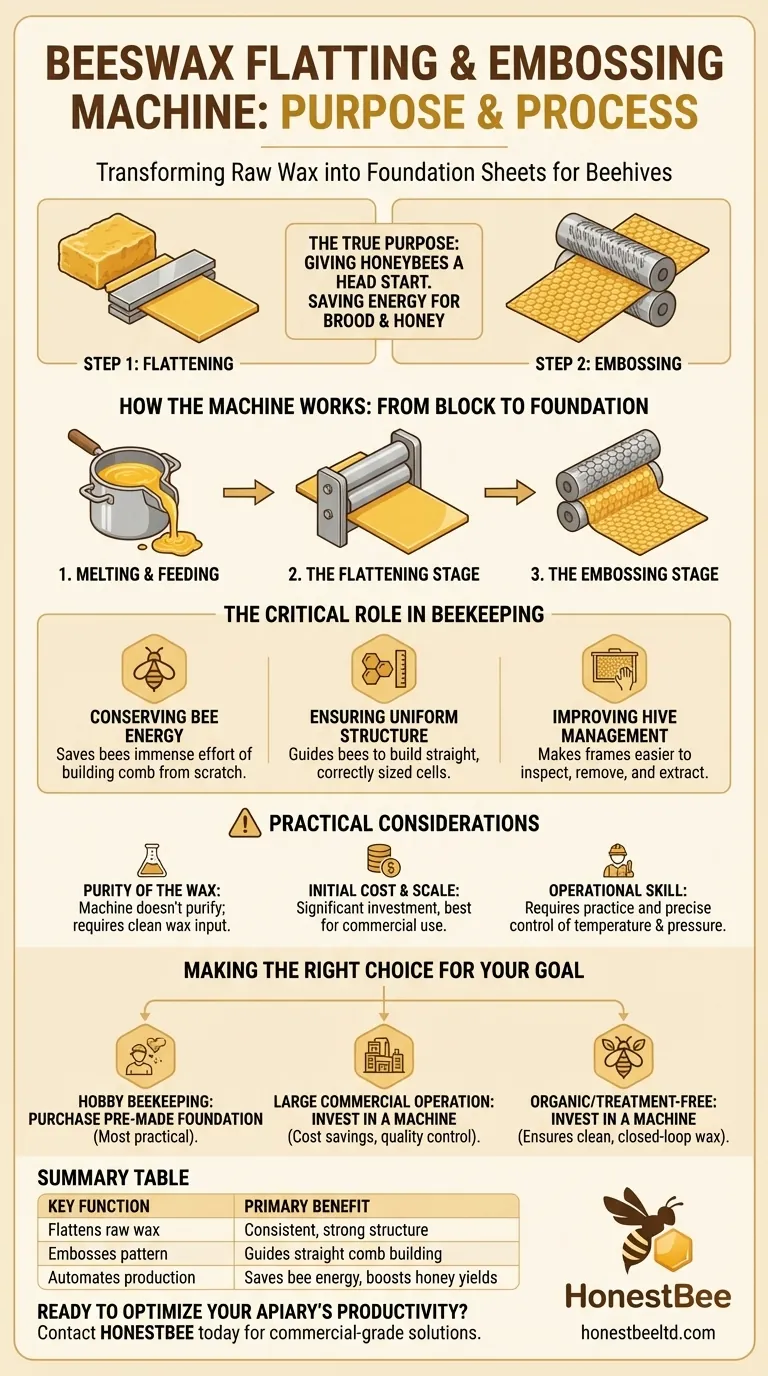

In short, the beeswax flatting and embossing machine is specialized equipment used to transform raw beeswax into perfectly patterned foundation sheets for beehives. It accomplishes this through a two-step process: first by pressing or rolling wax into a uniform, flat sheet, and then by imprinting it with the hexagonal honeycomb cell pattern that bees use as a guide for building their comb.

The true purpose of this machine is not just to shape wax, but to give honeybees a critical head start. By providing a pre-formed foundation, it conserves the bees' energy, allowing them to focus on raising brood and storing honey rather than on building the entire comb structure from scratch.

How the Machine Works: From Block to Foundation

The process of creating beeswax foundation is a straightforward mechanical operation that requires precision to produce a high-quality end product. It involves preparing the wax and then running it through the machine's primary systems.

Melting and Feeding the Wax

Before the machine can do its work, raw beeswax blocks or pellets must be melted into a liquid state. This is typically done in a separate wax melter. The molten wax is then carefully fed into the machine, ensuring an even and consistent flow onto a flat surface or conveyor system.

The Flattening Stage

This is the first core function of the machine. Using a system of precise rollers or a press mechanism, the machine applies consistent pressure to the molten wax. This action flattens the wax into a smooth, uniform sheet of a specific thickness.

The Embossing Stage

Once the sheet is formed, it passes through a set of engraved rollers. These rollers are imprinted with the negative of a perfect honeycomb pattern. As the wax sheet passes through, the hexagonal cell bases are pressed—or "embossed"—directly onto both sides of the sheet.

The Critical Role in Beekeeping

Providing bees with embossed foundation sheets is a fundamental practice in modern beekeeping. The benefits directly impact the health, productivity, and manageability of the colony.

Conserving Bee Energy

Bees produce wax from glands on their abdomens, a process that consumes a significant amount of energy derived from nectar or honey. By providing a foundation, the beekeeper saves the colony the immense effort of building the structural base of the comb, freeing up resources for other vital tasks.

Ensuring Uniform Comb Structure

The embossed pattern guides the bees to build straight, correctly sized cells. This uniformity is crucial for the queen to lay eggs efficiently and for workers to store honey and pollen in an organized manner. It leads to stronger combs that are less likely to break during hive inspections or honey extraction.

Improving Hive Management

Foundation encourages bees to build comb neatly within the hive frames. This makes it far easier for the beekeeper to remove frames for inspection, disease checks, and honey harvesting without damaging the comb or angering the colony.

Understanding the Practical Considerations

While essential for producing foundation, these machines are not a one-size-fits-all solution. There are practical trade-offs to consider before investing in one.

Purity of the Wax

The quality of the foundation sheet is entirely dependent on the quality of the beeswax used. The machine itself does not purify the wax, so it is critical to start with clean, well-rendered beeswax to avoid introducing contaminants into the hive.

Initial Cost and Scale

A beeswax flatting and embossing machine is a significant investment. For small-scale or hobbyist beekeepers, purchasing ready-made foundation is almost always more economical. These machines are best suited for large commercial operations or beekeeping clubs that can process wax in bulk.

Operational Skill

Achieving a consistently perfect sheet requires practice. Factors like wax temperature, roller speed, and roller pressure must be carefully controlled to produce foundation that is neither too brittle nor too soft.

Making the Right Choice for Your Goal

Deciding whether to produce your own foundation depends entirely on the scale and philosophy of your beekeeping operation.

- If your primary focus is hobby beekeeping: Purchasing pre-made foundation from a reputable supplier is the most practical and cost-effective approach.

- If your primary focus is large-scale commercial operation: Investing in a machine can offer long-term cost savings and complete control over the quality and purity of your foundation.

- If your primary focus is treatment-free or organic beekeeping: Processing your own beeswax ensures that you are returning clean, contaminant-free wax to your hives, which is a critical aspect of a closed-loop, self-sustaining apiary.

Ultimately, this machine serves as a powerful tool for efficiency, bridging the gap between a hive's raw resources and the beekeeper's need for a productive, manageable colony.

Summary Table:

| Key Function | Primary Benefit for Beekeepers |

|---|---|

| Flattens raw wax into uniform sheets | Ensures consistent, strong comb structure |

| Embosses hexagonal cell pattern | Guides bees to build straight combs for easy management |

| Automates foundation production | Saves bees energy, boosting honey and brood production |

Ready to optimize your apiary's productivity?

For commercial apiaries and equipment distributors, producing your own high-quality foundation is key to maximizing honey yields and hive health. HONESTBEE supplies the durable, wholesale-focused beekeeping equipment you need to scale your operations efficiently.

Contact HONESTBEE today to discuss your foundation production needs and discover our range of commercial-grade solutions.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- What equipment is needed to manually make wax foundation sheets? Essential Tools for High-Quality Beekeeping Foundation

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What are the key functions of a beeswax machine? Maximize Apiary Efficiency & Revenue with Professional Equipment

- What is the function of wax printers in modern beekeeping? Optimize Hive Efficiency & Honey Yield

- What is the likely cause and solution if a wax sheet feeds crookedly through the mill? Fix Your Dipping Technique

- What is the function of a manual wax roller? Master Hive Foundation Production with Precision

- How should the gears of a foundation mill be maintained? Essential Greasing Tips for Perfect Embossing

- What role do professional foundation embossing machines play? Unlock Maximum Honey Production & Hive Stability