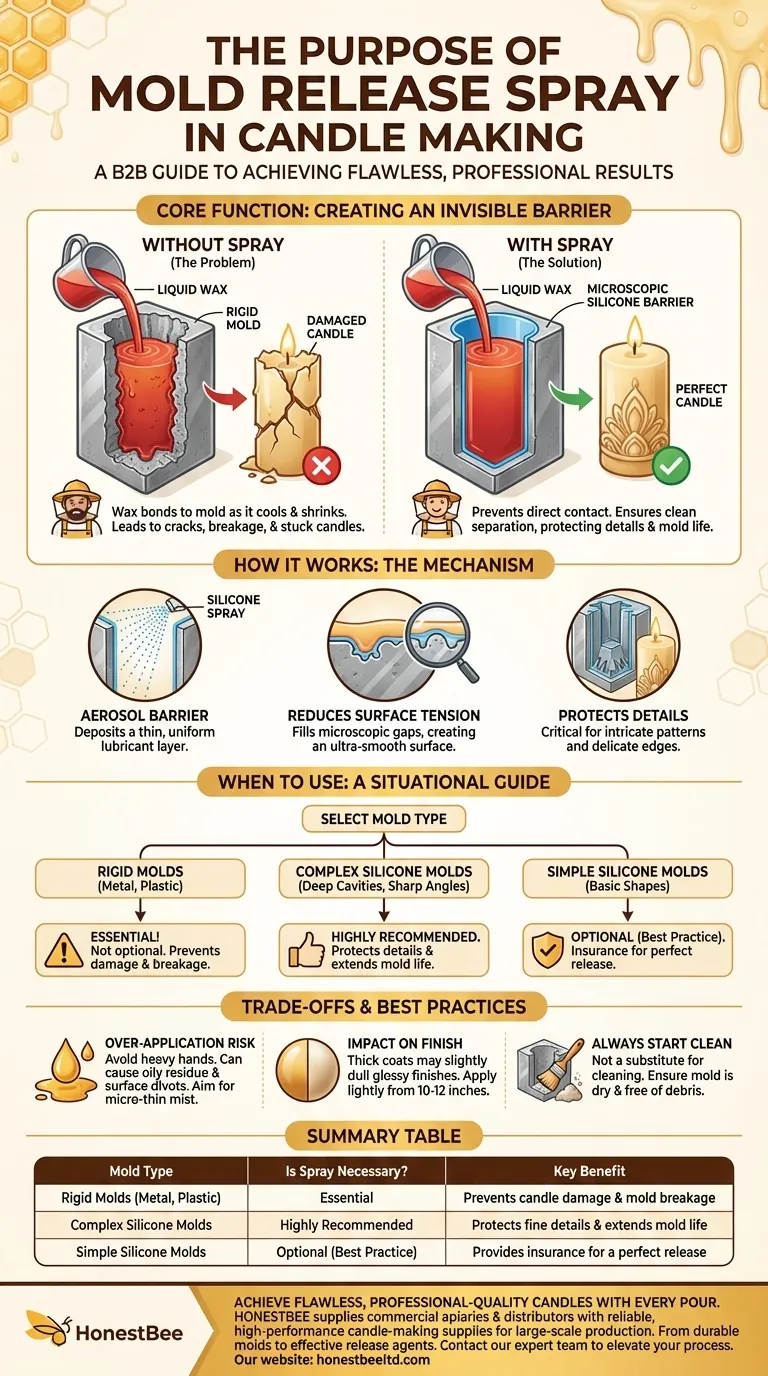

In candle making, mold release spray serves a single, critical purpose: to act as a releasing agent that prevents the cooling wax from adhering to the inside of a mold. It forms an invisible barrier that ensures your finished candle can be removed smoothly and without damage, protecting intricate details and preventing cracks or breakage.

The core issue is that as wax cools and shrinks, it can form a strong bond with the mold's surface. Mold release spray is an inexpensive insurance policy that lubricates the mold, guaranteeing a clean separation and protecting both your finished candle and the longevity of your mold.

The Core Mechanism: How Mold Release Works

The function of mold release spray is based on simple surface physics. It's not just a spray; it's a strategic tool for managing the interaction between two materials.

Creating a Microscopic Barrier

Mold release is typically a silicone-based aerosol. When sprayed into a mold, it deposits a very thin, uniform layer of lubricant over the entire interior surface.

This layer acts as a physical barrier, preventing the liquid wax from making direct contact with the mold material itself.

Reducing Surface Tension and Grip

Even surfaces that feel smooth have microscopic pores and imperfections. Wax can seep into these imperfections as it cools, creating a powerful grip.

The release spray fills these tiny gaps, creating an ultra-smooth surface that the shrinking wax cannot hold onto, allowing it to slide out effortlessly.

Protecting Detailed Designs

This principle is most critical for candles with intricate patterns, sharp edges, or delicate textures. Without a release agent, these fine details are the most likely points of failure, easily breaking off and remaining stuck in the mold.

When to Use Mold Release: A Situational Guide

Not every candle-making scenario requires mold release spray. The decision depends almost entirely on the type of mold you are using.

Essential for Rigid Molds

For molds made of metal, aluminum, or rigid polycarbonate, using a mold release spray is not optional. These materials have zero flexibility.

If the wax adheres to a rigid mold, you will likely have to break the candle to remove it. A light coat of release spray is mandatory for success.

Recommended for Complex Silicone Molds

While silicone is naturally flexible and has non-stick properties, it is not infallible. Molds with deep cavities, sharp angles, or highly detailed textures benefit significantly from a light misting.

This ensures that delicate parts of the candle do not tear or get snagged during the de-molding process, which also helps prevent tearing the silicone mold itself.

Optional for Simple Silicone Molds

For basic shapes like cylinders, spheres, or simple geometric pillars in a silicone mold, you can often get a clean release without any spray.

However, many experienced candle makers still use a very light coat as a best practice. It provides extra insurance against sticking and can help extend the working life of the silicone mold by reducing stress during de-molding.

Understanding the Trade-offs and Best Practices

Using mold release spray correctly is key. Improper application can create new problems instead of solving them.

The Risk of Over-Application

The most common mistake is using too much spray. A heavy hand will cause the release agent to pool in the bottom or crevices of the mold.

This can result in an oily residue on your finished candle or create divots and imperfections on its surface. The goal is a micro-thin, even mist, not a wet coating.

Potential Impact on Surface Finish

In rare cases, a thick application of release spray can slightly dull the finish of the candle, making a glossy surface appear more satin. This is another reason why a light, even application from about 10-12 inches away is the professional standard.

Always Start with a Clean Mold

Mold release spray is not a substitute for proper mold hygiene. Always ensure your mold is completely clean and dry before application. Any dust, debris, or old wax residue will be trapped by the spray and transferred to your new candle's surface.

Making the Right Choice for Your Project

Your goal dictates your method. Use this as a guide to determine the best approach for your specific candle-making process.

- If you are using rigid metal or plastic molds: Always use a light, even coat of mold release to prevent certain damage during de-molding.

- If you are working with intricate silicone molds with fine details: Use a very light mist of release spray to protect the candle's design and extend the life of your mold.

- If you are using simple silicone molds for basic shapes: Mold release is optional, but it serves as excellent insurance for a perfect result every time.

Ultimately, mastering the use of mold release spray is a mark of a deliberate candle maker who prioritizes consistency and quality.

Summary Table:

| Mold Type | Is Mold Release Spray Necessary? | Key Benefit |

|---|---|---|

| Rigid Molds (Metal, Plastic) | Essential | Prevents candle damage and mold breakage |

| Complex Silicone Molds | Highly Recommended | Protects fine details and extends mold life |

| Simple Silicone Molds | Optional (Best Practice) | Provides insurance for a perfect release |

Achieve flawless, professional-quality candles with every pour. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the reliable, high-performance candle-making supplies they need for consistent, large-scale production. From durable molds to effective release agents, our wholesale-focused operations ensure you have the right tools for success. Contact our expert team today to discuss your supply needs and elevate your candle-making process.

Visual Guide

Related Products

- Honeycomb Hexagonal Pillar Silicone Candle Mold for Candle Making

- Round Honeycomb Pillar Silicone Candle Molds for Candles

- 3D Beehive Silicone Skep Wax Candle Molds for Candles

- 3D Square Honeycomb Pillar Silicone Candle Molds for Making Beeswax Candles

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

People Also Ask

- What essential components are required for a beeswax candle-making kit? Professional Tools for High-Quality Production

- How do you remove the beeswax sheet from the silicone mold? A Guide to Perfect, Tear-Free Sheets

- What components are included in a beekeeping-related candle-making kit? Simplify Your Beeswax Candle Production

- What are the primary economic benefits for commercial apiaries to engage in beeswax candle production? Maximize Profits

- How do you secure a silicone mold for candle making? Prevent Leaks and Achieve Perfect Candles

- What is the process for pouring and molding cleaned beeswax? Master the Art of Perfect Wax Cooling and Storage

- What is the first tip for pouring beeswax into a silicone mold? Ensure a Perfect Release

- How do you keep beeswax from sticking to a mold? Master the Water Mist Method for a Perfect Release