The definitive best practice is to wire your beehive frames when they are brand new, completely empty, and have not yet been used in a hive. This must be done before you install the wax foundation. Attempting to wire a frame that already contains foundation or drawn comb is significantly more difficult, messy, and far less effective.

Wiring is not an optional step; it is the structural reinforcement for your comb. It prevents foundation from sagging in the hive's heat and keeps the heavy honeycomb from breaking apart during the centrifugal force of honey extraction, thereby protecting both your equipment and your harvest.

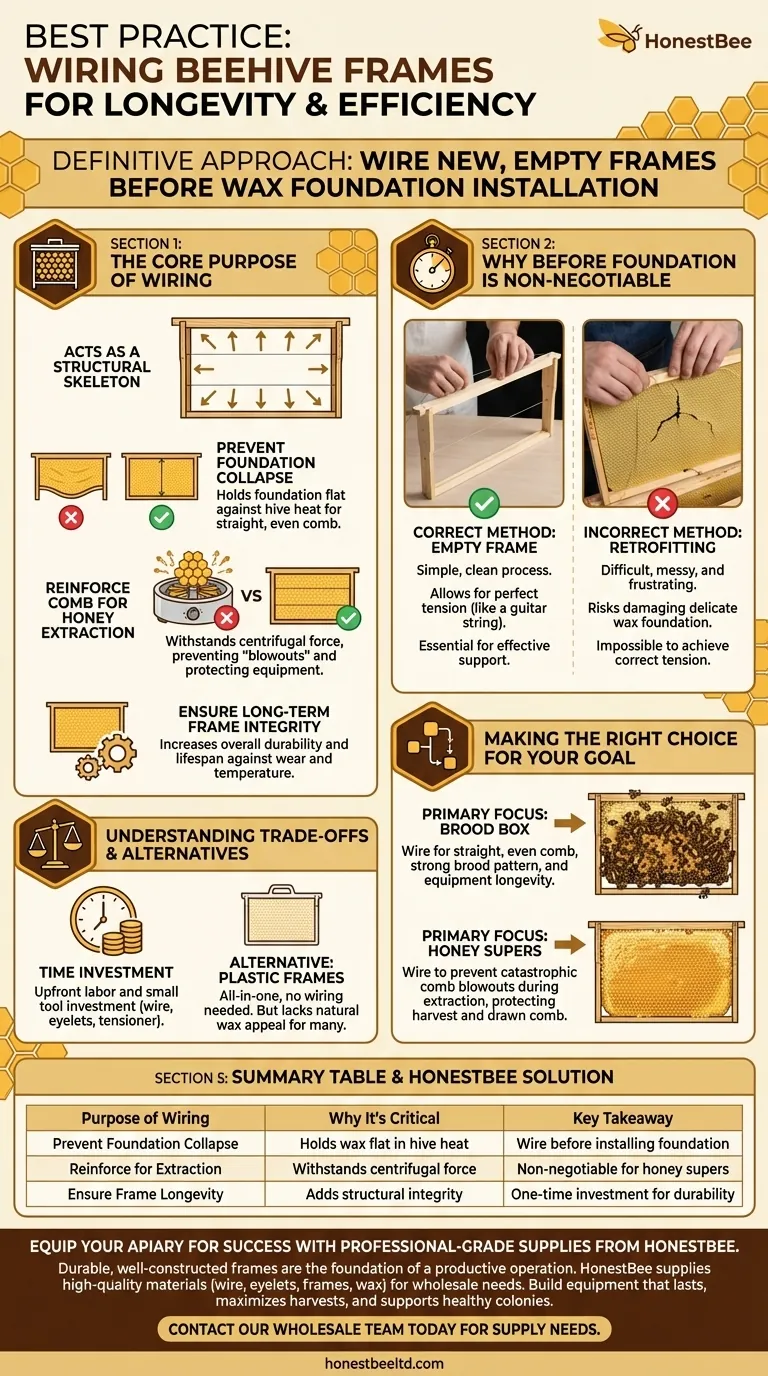

The Core Purpose of Wiring Frames

Understanding why you are wiring frames clarifies its importance for both brood chambers and honey supers. The wire acts as a skeleton within the wax, providing critical support against heat, weight, and force.

Preventing Foundation Collapse

Wax foundation is pliable and softens considerably in the warmth of a bustling hive. Without support, it can easily sag, warp, or collapse entirely.

Wiring creates a rigid grid that holds the foundation perfectly flat and centered. This encourages the bees to draw out straight, even comb, which is essential for a healthy brood pattern and efficient honey storage.

Reinforcing Comb for Honey Extraction

This is the most critical reason for wiring frames in your honey supers. A frame full of honey is incredibly heavy, yet the wax comb is fragile.

During extraction, the frames are spun at high speed. The immense centrifugal force will easily tear the comb apart—an event known as a "blowout"—if it is not reinforced by wires. Properly wired frames can withstand this process year after year.

Ensuring Long-Term Frame Integrity

Beehive frames endure years of inspections, movement, and temperature fluctuations. The tension from the wires helps hold the wooden frame itself together, adding to its overall durability and lifespan.

Why Wiring Before Foundation is Non-Negotiable

The timing of this task is just as important as the task itself. Integrating the wire into an empty frame is a simple, clean process; doing it later is impractical.

The Challenge of Retrofitting

Trying to thread wire through a delicate sheet of wax foundation without cracking or damaging it is exceptionally difficult. The process is frustrating and often results in a ruined foundation sheet.

A Clean and Taut Installation

Wiring an empty wooden frame allows you to pull the wire perfectly taut, like a guitar string. This tension is crucial for providing effective support. It is impossible to achieve the correct tension once a soft wax foundation is in the way.

Understanding the Trade-offs

While wiring is the recommended standard for wooden frames with wax foundation, it's important to understand the context of this choice.

The Time Investment

Wiring frames properly takes time and a small initial investment in tools like a wire spool, eyelets, and a tensioner. For beekeepers with many hives, this represents a significant upfront labor cost.

Alternatives to Wiring

The primary alternative is to use all-in-one plastic frames that have a foundation pattern molded directly into them. These do not require wiring.

However, many beekeepers prefer traditional wooden frames and natural wax foundation for their hives, which makes wiring an essential skill for ensuring the durability of that equipment.

Making the Right Choice for Your Goal

Your approach should be consistent, as the benefits apply to all parts of the hive.

- If your primary focus is the brood box: Wire your frames to guarantee straight, even comb for a strong brood pattern and to maximize the lifespan of your core equipment.

- If your primary focus is the honey supers: Wire your frames to prevent catastrophic comb blowouts during extraction, which protects your honey harvest and preserves the drawn comb for future seasons.

Investing the time to properly wire your new frames is a foundational step that pays dividends in hive productivity, harvest efficiency, and equipment longevity.

Summary Table:

| Purpose of Wiring | Why It's Critical | Key Takeaway |

|---|---|---|

| Prevent Foundation Collapse | Holds wax foundation flat in hive heat for straight comb. | Wire before installing foundation. |

| Reinforce for Extraction | Withstands centrifugal force to avoid honeycomb blowouts. | Non-negotiable for honey supers. |

| Ensure Frame Longevity | Adds structural integrity to the wooden frame itself. | A one-time investment for durable equipment. |

Equip your apiary for success with professional-grade supplies from HONESTBEE.

For commercial beekeepers and equipment distributors, durable, well-constructed frames are the foundation of a productive operation. Properly wiring frames is a critical step that we understand deeply.

HONESTBEE supplies the high-quality materials you need—from frame wire and eyelets to durable wooden frames and wax foundation—through our wholesale-focused operations. Let us help you build equipment that lasts, maximizes honey harvests, and supports healthy colonies.

Contact our wholesale team today to discuss your supply needs and ensure your frames are built to the highest standard.

Visual Guide

Related Products

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- Professional Galvanized Steel Frame Rest for Beehives

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

- Professional Frame Comb Fork and Lifter for Efficient Handling

People Also Ask

- When should I throw away my bee frame? A Guide to Hive Health & Frame Rotation

- What are some tips for setting up hive frames? Build a Strong Foundation for Your Hive

- What are the functions of wooden frames and wax sheets in beehive management? Optimize Your Apiary's Efficiency

- What are the best practices for assembling beekeeping frames? Pro Tips for Maximum Durability & Efficiency

- What are the small wooden 'frames' used for in beekeeping? Essential Tools for Hive Organization and Honey Storage