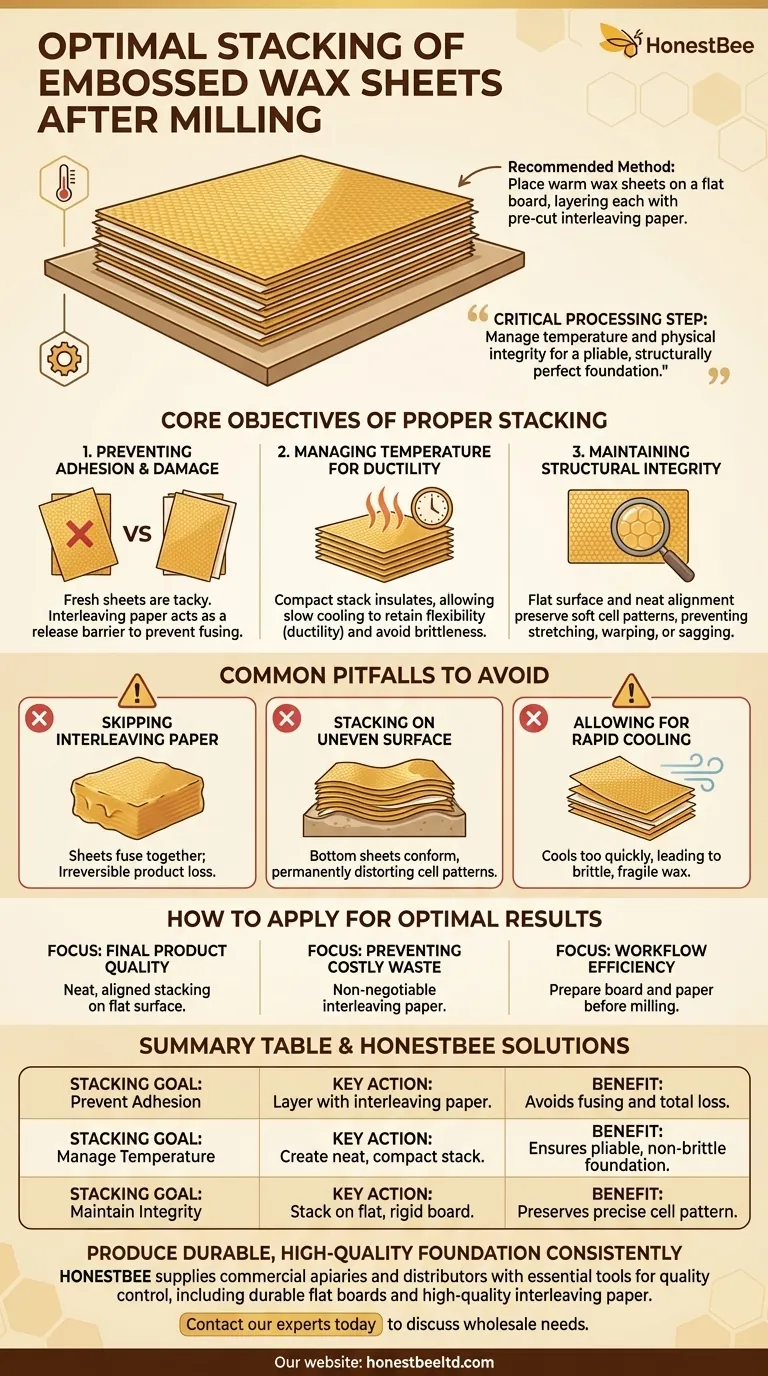

To properly stack embossed wax sheets after milling, you must place them neatly on a flat board or plate, layering each sheet between a sheet of pre-cut paper. This method prevents the warm, tacky sheets from sticking to each other and helps the stack retain an even temperature, which is critical for the quality of the final product.

Stacking embossed foundation is not just about storage; it's a critical processing step. The goal is to manage both temperature and physical integrity, using the residual heat from milling to ensure the final wax foundation is pliable, structurally perfect, and easy to handle.

The Core Objectives of Proper Stacking

The method for stacking freshly milled wax sheets is designed to achieve three specific goals simultaneously. Understanding these objectives clarifies why each step is essential.

Preventing Adhesion and Damage

Freshly milled wax sheets are warm, soft, and tacky. If stacked directly on top of each other, they will quickly fuse into a single, inseparable block.

Using interleaving paper between each layer of wax acts as a release agent. This simple barrier is the most effective way to prevent sticking and ensure each sheet remains separate and usable.

Managing Temperature for Ductility

A neat, compact stack acts as an insulator, allowing the wax sheets to cool down slowly and evenly. This process is crucial for retaining ductility.

Ductile wax is pliable and flexible, resisting cracks when it's handled or installed in a frame. Wax that cools too quickly becomes brittle and fragile. Retaining the warmth from milling improves the final quality of the foundation.

Maintaining Structural Integrity

The cell pattern on a freshly embossed sheet is soft and easily distorted. Stacking the sheets on a perfectly flat board and keeping the stack neatly aligned is vital.

This prevents the sheets from stretching, warping, or sagging under their own weight while they are still warm. Any distortion can alter the cell size and shape, making the foundation less effective for the bees.

Common Pitfalls to Avoid

Mistakes made during stacking can easily ruin a batch of foundation. Being aware of these common errors is key to preventing waste and frustration.

Skipping the Interleaving Paper

This is the most critical mistake. Without a barrier, the sheets will fuse together. This damage is irreversible and results in a complete loss of the product.

Stacking on an Uneven Surface

Placing a stack of warm, soft wax on an uneven surface will cause the sheets at the bottom to conform to that shape, permanently distorting the cell pattern. Always use a rigid, flat board or plate.

Allowing for Rapid Cooling

Stacking the sheets loosely or in a cold, drafty area will cause them to cool too quickly. This leads to brittle wax that can easily crack or break during subsequent handling. A neat, tight stack is essential for gradual cooling.

How to Apply This for Optimal Results

Your specific focus will determine which part of the process you need to emphasize most.

- If your primary focus is final product quality: Emphasize neat, aligned stacking on a flat surface to preserve perfect cell integrity and ensure uniform ductility.

- If your primary focus is preventing costly waste: Using interleaving paper between every single sheet is the non-negotiable step to prevent them from fusing together.

- If your primary focus is workflow efficiency: Prepare your flat board and pre-cut paper sheets before you begin milling to create a smooth, uninterrupted process.

Mastering this simple post-milling process is fundamental to producing durable, high-quality beeswax foundation.

Summary Table:

| Stacking Goal | Key Action | Benefit |

|---|---|---|

| Prevent Adhesion | Layer each wax sheet with interleaving paper. | Prevents sheets from fusing together, avoiding total loss. |

| Manage Temperature | Create a neat, compact stack. | Ensures slow, even cooling for a pliable, non-brittle foundation. |

| Maintain Integrity | Stack on a perfectly flat, rigid board. | Preserves the precise cell pattern and prevents warping. |

Produce Durable, High-Quality Foundation Consistently

Perfecting the post-milling process is critical for commercial-scale success. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the essential tools for quality control, including durable flat boards and high-quality interleaving paper designed for this exact purpose.

Contact our experts today to discuss your wholesale needs and ensure every batch of your beeswax foundation meets the highest standard of quality.

Visual Guide

Related Products

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Plastic Handle Single Row Artificial Fiber Bee Brush

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What is the use of a comb foundation mill? Boost Honey Production with Strategic Hive Control

- What texture is embossed on the beeswax foundation machine? The Precise Worker Bee Cell Pattern for Hive Efficiency

- What is the primary function of a manual honeycomb embossing machine? Create Custom Beeswax Foundations with Ease

- Why is the introduction of a beeswax foundation machine considered an important step in improving honey yields?

- What are the primary applications of fully automatic wax foundation machines? Maximize Your Apiary Production Efficiency