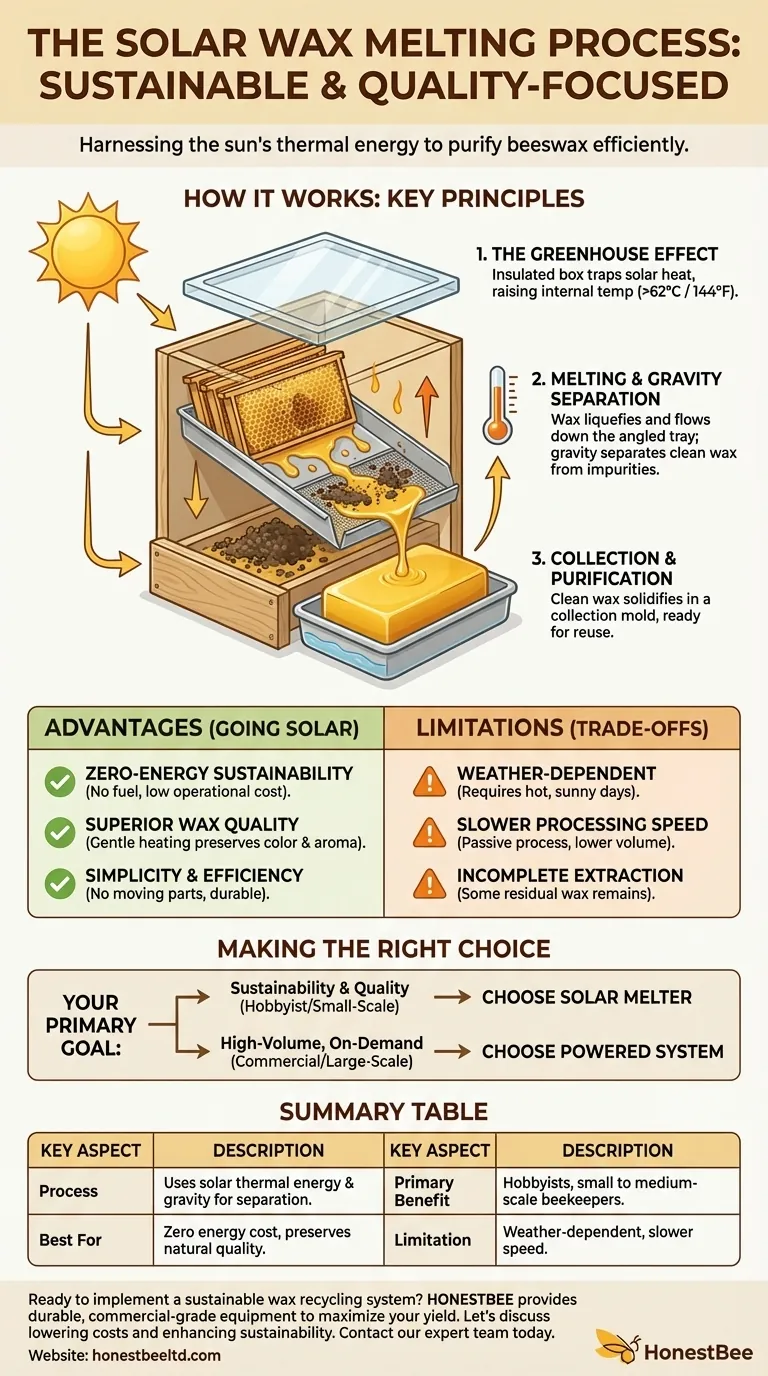

At its core, the solar wax melting process is a sustainable method that uses the sun's thermal energy to melt and purify beeswax from old honeycombs. An insulated box with a transparent top traps solar heat, raising the internal temperature above the melting point of wax (>62°C or 144°F), causing pure, liquid wax to separate from impurities and drain into a collection mold.

Beekeepers constantly cycle out old honeycomb, which contains valuable wax trapped with debris. The core challenge is how to reclaim this wax efficiently and cost-effectively. A solar wax melter solves this by providing a passive, energy-free solution that yields high-quality, reusable beeswax.

How a Solar Wax Melter Works: The Key Principles

A solar wax melter is a simple yet highly effective device. Its operation relies on a few fundamental principles of physics and smart design to separate valuable wax from waste.

The Greenhouse Effect in a Box

The melter is essentially an insulated box with a tight-fitting, transparent lid, usually made of glass or a durable double-webbed polycarbonate.

This design creates a miniature greenhouse. Sunlight passes through the lid and is absorbed by the dark combs and the interior surfaces of the box, converting it into heat. The insulated walls and sealed lid prevent this heat from escaping, allowing the internal temperature to build steadily.

Separation Through Melting and Gravity

Inside the box, old combs or frames are placed on a sloped metal tray or mesh screen. As the temperature rises above beeswax's melting point, the wax liquefies.

Because the entire device is angled, gravity pulls the liquid wax downwards. It flows down the sloped tray, leaving heavier debris like cocoons, pollen, and other impurities (collectively known as "slumgum") behind on the screen.

Collection and Purification

At the bottom of the slope, the clean, liquid wax drips into a collection pan or mold. This pan can sometimes contain a small amount of water, which helps the wax cool and solidify into a clean block, often with any remaining fine impurities settling at the bottom.

The result is a solid block of bright, clean beeswax, ready for reuse in making new foundation sheets or for other purposes like candlemaking.

The Advantages of Going Solar

Choosing a solar melter is a strategic decision that offers distinct benefits over powered alternatives, especially for small to medium-scale beekeepers.

Unmatched Sustainability

The most significant advantage is its zero-energy consumption. A solar melter requires no electricity, gas, or other fuel, which eliminates operational costs and minimizes your environmental footprint.

Superior Wax Quality

The process involves slow, gentle heating. This prevents the wax from being scorched or overheated, which can happen with direct heating methods. This gentle process preserves the wax's natural color and aroma, resulting in a premium-quality final product.

Simplicity and Efficiency

Solar melters are remarkably simple. With no moving parts, they are durable and require minimal maintenance. For maximum efficiency, many models are designed to be rotated throughout the day to track the sun's path across the sky, ensuring optimal heat absorption.

Understanding the Trade-offs and Limitations

While highly effective, a solar wax melter is not the perfect solution for every situation. Its effectiveness is bound by certain constraints that you must consider.

It's Entirely Weather-Dependent

The primary limitation is its reliance on the sun. The process only works effectively on hot, sunny days. It is inefficient or completely unusable during overcast weather, in cooler climates, or during winter months.

Processing Speed and Capacity

Solar melting is a passive and relatively slow process. While it can process a surprising amount of wax over a long summer day, it cannot match the high-speed, high-volume output of electric or steam-based wax renderers used in large commercial operations.

Incomplete Wax Extraction

While a solar melter is very good at separating clean wax, it is not 100% efficient. Some residual wax will always remain trapped in the slumgum left behind on the melting tray. More aggressive methods like steam presses can extract a slightly higher percentage of wax, but often at the cost of energy and equipment complexity.

Making the Right Choice for Your Goal

To decide if a solar wax melter is the right tool, consider your primary objective as a beekeeper.

- If your primary focus is sustainability and low operational cost: A solar wax melter is the ideal, eco-friendly choice for any hobbyist or small-scale operation.

- If your primary focus is preserving wax quality: The gentle, even heat of a solar melter is superior to most powered methods that risk scorching the wax.

- If your primary focus is high-volume, on-demand processing: You will likely need to invest in a steam or electric rendering system better suited for large-scale commercial needs.

By understanding its principles and trade-offs, you can effectively harness the sun's free energy to reclaim one of the hive's most valuable resources.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Uses solar thermal energy in an insulated box to melt beeswax, separating it from debris via gravity. |

| Primary Benefit | Zero energy cost, sustainable, and preserves the natural quality of the wax. |

| Best For | Hobbyists and small to medium-scale beekeepers focused on sustainability and wax quality. |

| Limitation | Weather-dependent; slower processing speed compared to powered alternatives. |

Ready to implement a sustainable wax recycling system?

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-efficiency equipment you need to maximize your wax yield. Our wholesale-focused operations ensure you get reliable, commercial-grade solar wax melters and other essential beekeeping supplies.

Let's discuss how our solutions can lower your operational costs and enhance your sustainability efforts. Contact our expert team today for a consultation.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results