For most beekeepers, the standard for filtering honey is a 600-micron mesh. This size effectively removes the majority of wax, propolis, and other hive debris while preserving the beneficial pollen grains that are characteristic of raw, unprocessed honey.

The goal of filtering is not simply to achieve clarity, but to strike a critical balance between removing unwanted debris and retaining the natural, beneficial components of the honey, like pollen.

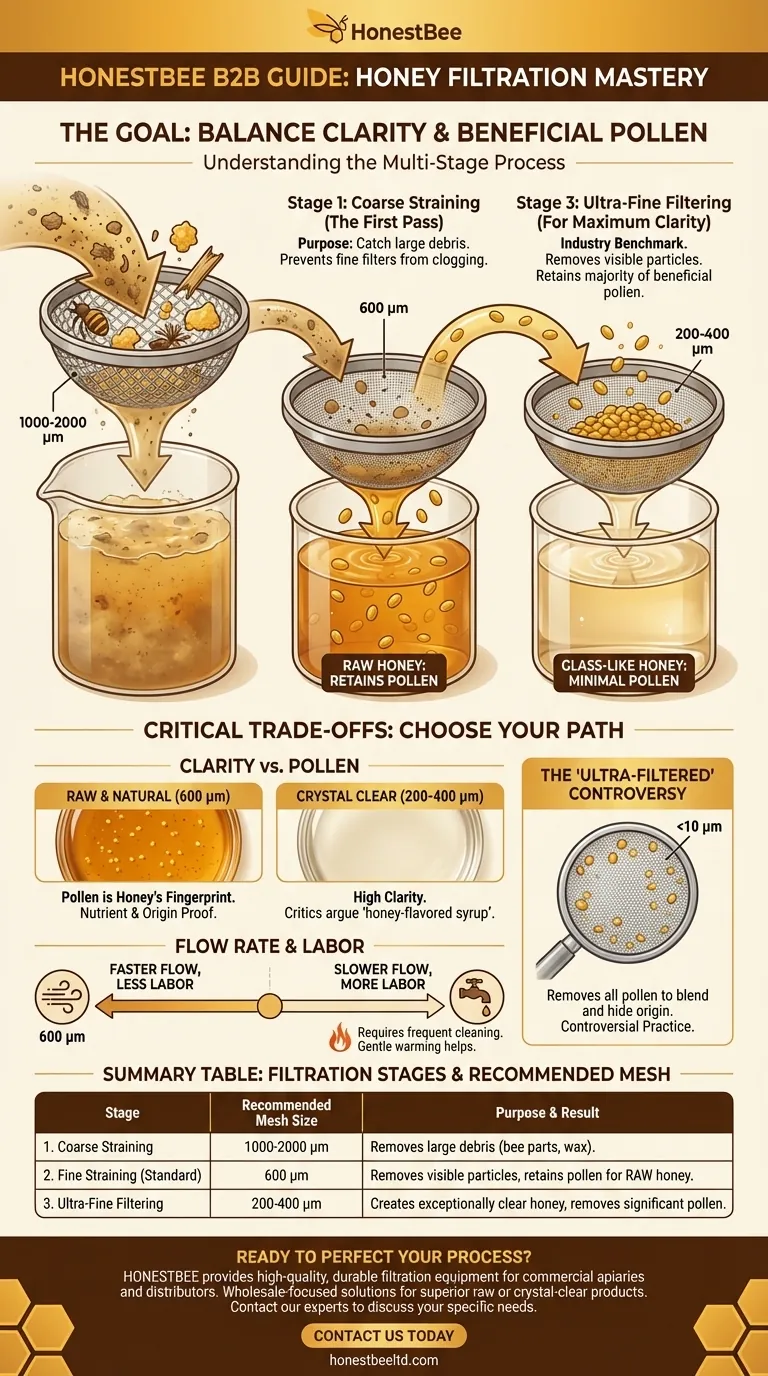

Understanding Honey Filtration: A Multi-Stage Process

Effective honey processing isn't about using a single filter. It's a staged approach that progressively removes smaller and smaller particles, giving you control over the final product.

### The Goal of Straining vs. Filtering

First, it's important to clarify the terms. Straining typically refers to removing large, visible debris, while filtering removes much finer particles. For beekeepers, both are part of the same process.

### Stage 1: Coarse Straining (The First Pass)

Your initial pass should use a coarse strainer, often in the 1000 to 2000-micron range (1-2 mm).

The sole purpose of this stage is to catch large debris like bee parts, chunks of wax, and splinters of wood directly after extraction. This prevents the finer filters from clogging immediately.

### Stage 2: Fine Straining (The "Raw Honey" Standard)

This is the most critical stage and where the 600-micron filter is used.

A 600-micron mesh is the industry benchmark for producing clean honey that can still be classified as raw. It removes suspended particles visible to the naked eye without stripping out the vast majority of pollen.

### Stage 3: Ultra-Fine Filtering (For Maximum Clarity)

For honey that is exceptionally clear, some producers use filters in the 200 to 400-micron range.

This step removes even more suspended solids, including a significant portion of the pollen. The result is a glass-like honey, but it comes at the cost of removing some of the honey's natural character.

Understanding the Trade-offs: Clarity vs. Pollen

Choosing a filter size is a decision that directly impacts the quality and characteristics of your final product. There is no single "best" size, only the right size for your specific goal.

### The Value of Retaining Pollen

Pollen grains are like a fingerprint for honey. They prove its floral source and geographical origin, and they contain trace amounts of nutrients and proteins.

Removing all the pollen creates a product that some critics argue is no longer true honey, but rather a "honey-flavored syrup."

### The Impact on Flow Rate and Labor

The finer the mesh, the slower the honey will flow. This is a significant practical consideration.

A 200-micron filter will clog much faster than a 600-micron one, requiring more frequent cleaning and making the process much more labor-intensive. Warming the honey slightly (never above hive temperature, ~95°F/35°C) can help improve flow without damaging it.

### The "Ultra-Filtered" Commercial Practice

Large-scale commercial honey is often ultra-filtered at sizes below 10 microns. This process removes all pollen and is sometimes used to blend and hide the honey's country of origin, a controversial practice in the industry.

Choosing the Right Mesh for Your Goal

To select the correct system, first define what kind of honey you want to produce.

- If your primary focus is producing raw, natural honey for home use or local sale: Use a two-stage system with a coarse pre-filter followed by a 600-micron filter.

- If your primary focus is creating crystal-clear honey for competition or specialty markets: Consider a three-stage system, finishing with a 400-micron or even 200-micron filter, but be aware you are removing beneficial pollen.

- If your primary focus is simplicity and efficiency with small batches: A single 600-micron filter can work, but expect it to clog and require cleaning as you work.

Ultimately, the right filter empowers you to control the final character of your honey.

Summary Table:

| Filtration Stage | Recommended Mesh Size | Purpose & Result |

|---|---|---|

| Stage 1: Coarse Straining | 1000 to 2000 microns | Removes large debris like bee parts and wax chunks. |

| Stage 2: Fine Straining (Standard) | 600 microns | Removes visible particles while retaining pollen for raw honey. |

| Stage 3: Ultra-Fine Filtering | 200 to 400 microns | Creates exceptionally clear honey but removes significant pollen. |

Ready to perfect your honey filtration process?

As a trusted supplier for commercial apiaries and distributors, HONESTBEE provides the high-quality, durable filtration equipment you need to scale your operation efficiently. Our wholesale-focused solutions ensure you get the right tools to produce superior raw honey or crystal-clear products for your market.

Contact our experts today to discuss your specific needs and discover how our beekeeping supplies can enhance your honey's quality and your operation's productivity.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Stainless Steel Honey Filter with Support Handle

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Two-Stage Plastic Honey Filter for Buckets

People Also Ask

- What is the role of filtration in honey processing? Ensure Purity, Clarity, and Shelf Life

- What are the benefits of drying honey filtering equipment after use? Protect Your Honey Quality & Equipment Investment

- Why are dual filtration sieves used in honey processing? Balance Purity & Nutrition for Professional Honey Production

- How does automated honey filtration and filling machinery improve quality? Guard Your Apiary Against Pest Contamination

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality